Aug 13 2019

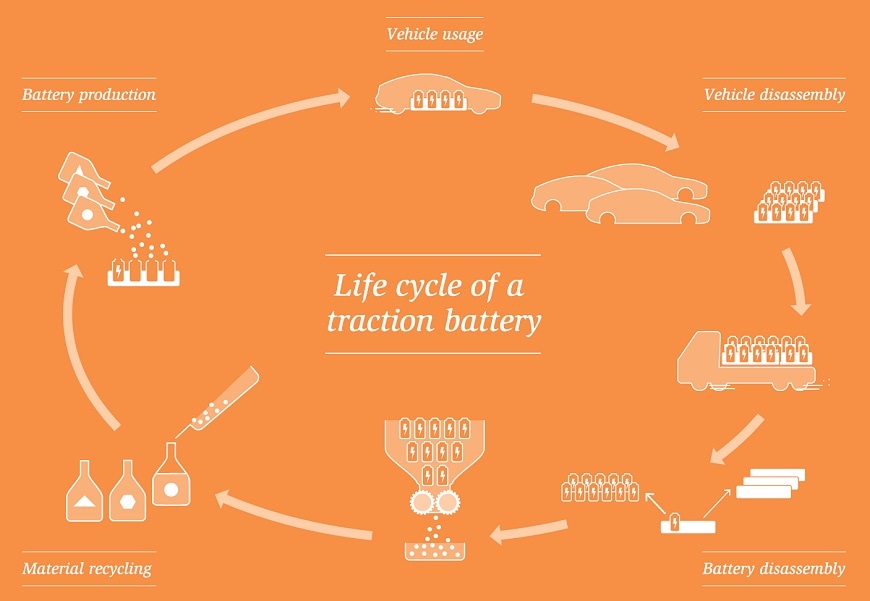

There has been a sudden increase in the number of registrations of electric cars. However, what is the solution to dump used batteries? The association of Swiss car importers, “auto-schweiz,” is working hard to find a recycling solution for the whole industry, with Empa experts supporting it.

(Image credit: Empa)

(Image credit: Empa)

The serrated metal roller crunches and eats all the way through the battery modules, powders the plastic frames, slices the silver foils of the lithium polymer packs, and shreds everything into pieces. The end product is a fine powder. If it is subsequently treated with a number of acid baths, salts and oxides are produced, which can be used to construct new batteries.

The YouTube video “Neue Recycling-Methode für Batterien aus Elektroautos,” released in May 2019, displays something that has never been witnessed before—the shredding of lithium-ion batteries. This process looked impossible since these batteries are flammable. Just a little bit of electrical voltage and a single spark is sufficient to turn everything into ashes.

Therefore, Duesenfeld, a German company, fully discharges the batteries and fills the airtight shredder with nitrogen. Prior to the removal of the powder, the flammable electrolyte liquid is evaporated and emptied. In this manner, 96% of all materials in the battery can be recycled.

At present, about 40,000 electric cars and plug-in hybrids with lithium-ion batteries are running on Swiss roads—just below 1% of the whole vehicle fleet. Soon, there will be more. From January to March 2019, the new registrations already increased to 5.3%.

Moreover, this is just the start—a complete series of high-performance electric cars will hit the market later this year: Mercedes EQC, Audi e-tron, Peugeot e-208, to name a few. These models will conform to the Tesla Model 3, which has been at the top of the registration statistics since March 2019.

Next year, the VW Group will introduce its first electric mass-market automobile—the VW iD.3. Hence, it is the right time to think about the fate of the batteries when these cars stop working or are scrapped at the end of their lives.

A Recycling System for Car Importers

The association “auto-schweiz,” representing a majority of the Swiss car importers, is fully aware of this issue. Hence, in 2018, car importers sought the help of Empa to estimate the cornerstones of a recycling system for car batteries. Empa had already informed other industry associations such as Swico on the recycling of electronic devices and computer technology.

However, unlike electronic products, there has been no early recycling fee charged for cars so far. auto-schweiz is trying hard for an industry solution and has appointed the Swiss Auto Recycling Foundation to create such a solution. Since 1992, this foundation has been in charge of the dismantling and recycling of end-of-life vehicles in Switzerland.

Empa scientist Rolf Widmer and his team from Empa’s “Technology and Society” lab have been collaborating with the Auto Recycling Foundation on this project since March 2019. They examine recycling systems in neighboring countries, analyze costs and the ecological footprint, and create model calculations in order to predict the future quantities of old batteries—and, finally, propose appropriate policies.

Hot or Cold Recycling?

The majority of lithium-ion batteries are not cold shredded, just as in the case of the Duesenfeld method discussed above; they are rather burnt in an oven prior to being crushed. Umicore, a Belgian company, is the market leader.

While performing hot recycling, the thin copper foils of the battery melt and, along with nickel and cobalt, they form an alloy that is recyclable. However, the battery’s graphite, lithium, liquid electrolyte, and aluminum burn and end up in the slag. They can no longer be reused.

Besides hot Umicore recycling and cold shredding under inert gas, there are other automated dismantling techniques as well. Batrec Industrie AG, a Swiss battery-recycling specialist, shreds some batteries in a wet environment to avoid fires. The Empa experts will do a comparison of all these techniques.

The Transport Problem

However, the hunt for the best recycling system is not only about shredding but also about creating a supply chain.

Traction batteries of vehicles damaged in an accident can burn suddenly and have to be transported as hazardous goods in special containers thus far.

Daniel Christen, Managing Director, Swiss Auto Recycling Foundation

This is expensive and time-consuming. Christen is searching for a more economical solution to “disarm” batteries and supply them to disposal companies.

Already there exist techniques for this purpose: Blubox Trading AG in Birrwil, for instance, employs the “Firebox” from a Dutch producer. The Firebox is a shipment container with an integrated fire extinguishing system that can accommodate a whole car or a larger charge of “disarmed” batteries.

Last but not least, the car recyclers and forwarding agents should be given training so that dismantled electric cars do not turn dangerous. A database for rescue workers is already available that offers this type of information: On a tablet, the firefighter enters the number of the license plate and can spot an electric car on the site. The tablet displays the way the battery must be disconnected. With the same information, electric cars could also be decommissioned safely.

Many Questions Still Unanswered

However, there are still several open questions that must be answered prior to setting up a recycling system. How will the market for used batteries grow? Will it someday be valuable repairing exhausted battery packs with new modules and returning them to the market—just like refurbished gearboxes or engines?

Will old car batteries instead become stationary solar power storage units in their “second life”? How long will it take for dismantled batteries to arrive at the recycling companies? Does Switzerland require large recycling capacities in any way, or will car producers overseas gather and recycle most of the batteries themselves?

Most of them will rely on the value of lithium, cobalt, nickel, and graphite, on the market prices of the raw materials, on the price and performance of new batteries, as well as on politics, which can establish the framework conditions and issue regulations.

Whatever the case may be, the good news is that electric cars are not a recycling issue. All steps of the recycling process are technically practicable. And several specialists are already working on it.

Source: https://www.empa.ch/