Interview conducted by Lee PickeringJan 5 2022

Interview conducted by Lee PickeringJan 5 2022As a company, Composition Materials has been active since 1923. Since that time, the company has specialized in value-added fillers for use worldwide in the manufacturing, aviation, paint and coatings, aerospace, automotive, medical, non-skid, engineered surfaces, electronics, rubber and cosmetics industries.

Virtually all of Composition Materials’ fillers and abrasives are manufactured from raw materials obtained from sustainable, recycled, or renewable sources.

The company has continued this tradition since its founding, developing ‘green’ products suitable for numerous uses and applications.

What products does Composition Materials offer, and how has this product offering evolved over the years?

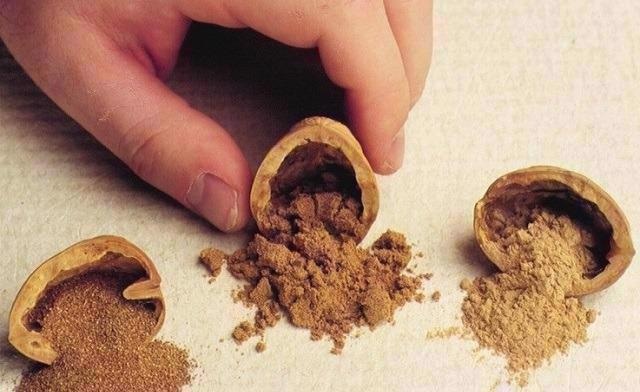

Composition Materials' specialty has been to repurpose and recycle by-products of various industries. From the agricultural sector, we have produced abrasives and fillers from Walnut Shells, Apricot Shells, Pecan Shells, Almond Shells, Rice Hulls and Corn Cob.

We started to manufacture products made from ground walnut shell in the 1950s. These products were initially employed in filler applications before seeing further use in pressure blasting for blast cleaning and paint removal.

Ground walnut shells offer a number of unique and beneficial characteristics owing to their hardness and angularity of their component particles. Walnut shell products are also 100% natural, renewable and biodegradable.

In the 1980s the cosmetics industry start to include natural raw ingredients in products, a trend which saw us begin to supply ground and classified walnut shell and apricot shell designed for use in personal care products.

These products have been popular options for more than 30 years with cosmetics companies around the world using these in formulations for scrubs, soaps, hand cleaners and exfoliation products.

Are there any natural products that Composition Materials was prompted to develop specifically for the cosmetics industry?

We have been supplying ground walnut shells to a number of industries since the 1950s, and this has given us many years of expertise in the grinding, classifying, quality control, and packaging of these materials.

We were approached by one of the earliest active cosmetic companies in the 1980s, and this company was specifically looking for formulations with natural raw ingredients.

Ground walnut shell and apricot shell proved ideal for use in cosmetics, particularly scrubs, soaps, and personal care formulations, due to their excellent exfoliating action, consistency, and versatility. We also helped develop the use of almond meal in cosmetics applications.

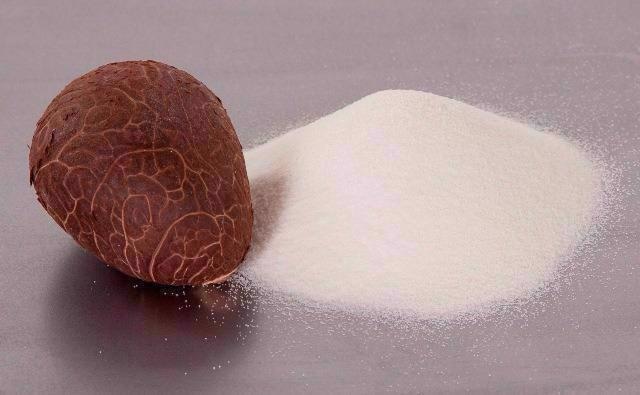

In 2005, we developed a 100% natural white exfoliator to meet demands from the industry. This is made from Tagua which is a renewable and sustainably sourced ingredient from the rainforests of South America. Tagua has proven to be an attractive option for cosmetic formulators looking for a 100% natural biodegradable ingredient in an appealing white color.

Our Tagua comes from a sustainable supply in South America, and using and harvesting Tagua helps protect these rainforest trees from deforestation.

We have assisted many cosmetic companies in selecting the most effective and applicable ingredient type and size for their product and target market.

Figure 1. Walnut Shell for Cosmetics.

Image Credit: Composition Materials

Where are your products grown?

California is the largest grower of the raw materials used in our products. We have also worked with South America and Turkey.

What does sustainability mean to you personally and to Composition Materials as a company?

For us, sustainability refers to the capacity for the ingredient to be replenished with every new crop. Since crops such as apricot, walnut, almond, pecan, and tagua are derived from fruits, nuts or seeds grown on trees, these materials naturally replenish every year.

As we specifically use the shells of walnut, apricot, and pecan, we can acquire these as by-products of the food industry and produce versatile abrasives, fillers and powders sustainably.

What does the current market for sustainable microbead alternatives look like, and how has this evolved over the years?

The US passed legislation to ban the use of plastic microbeads in personal care products with the Microbead-Free Waters Act of 2015.

New laws, and a general interest in sustainable and enviornmentally friendly products from consumers, have led to an increased demand for natural raw ingredients internationally. We anticipate this demand will continue to grow as cosmetics and personal care companies look for more cost-effective, sustainable microbead alternatives.

Companies from many other industries are also seeking natural abrasives, fillers and raw ingredients for a variety of applications.

As well as ensuring products are legally compliant, what are the other advantages of these natural products?

The biggest advantage to using our natural products is environmental. The harm caused by plastic microbeads was widely researched and recognized, and banning these tiny plastic particles from cosmetic products has had a positive environmental effect.

The other key advantage is sustainability. Cosmetic companies are under increasing pressure from both consumers and regulatory bodies to be more sustainable, prompting them to look at natural products, such as walnut shell, apricot shell and tagua, which offer biodegradable, sustainable options.

Figure 2. Tagua Cosmetic White Exfoliant.

Image Credit: Composition Materials

Have there been any notable challenges to supplying natural products in the cosmetics industry?

Cosmetics companies sometimes prefer uniformity in their products’ color, and they tend to develop products in a variety of colors that may not naturally occur. With consumer demand for environmentally friendly products increasing, formulators are becoming more interested in developing products that incorporate natural ingredients. Our Tagua product is a natural white color making this a good option when a white color is required.

Figure 3. Apricot Pit Shell for Cosmetics.

Image Credit: Composition Materials

Have these challenges been difficult to overcome?

We have worked with agricultural by-products since the company was founded in 1923. Our expertise and experience allow us to manufacture consistent products in terms of supply and quality.

We look forward to continue to develop green solutions for the personal care industry as well as other industries for years to come.

About Alan Nudelman

Alan Nudelman is President Emeritus of Composition Materials Co., Inc.

Since 1923, Composition Materials has specialized in value-added fillers and abrasives for industries worldwide including manufacturing, paint & coatings, aviation, aerospace, automotive, medical, non-skid, engineered surfaces, and cosmetics.

Nearly all of the fillers and abrasives supplied by Composition Materials are manufactured from raw materials that are from recycled, sustainable, or renewable sources.

This information has been sourced, reviewed, and adapted from materials provided by Composition Materials.

For more information on this source, please visit Composition Materials.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.