In the chemical industry, ethylene oxide (EtO) is known as a carcinogenic and mutagenic compound that has been commonly utilized, especially as a sterilant for medical products and as a reaction intermediate in the production of ethylene glycol.

Image credit: Thermo Fisher Scientific

As a result of its toxicity, state, federal and local regulators have expressed an interest in tracking very low levels of EtO in and around commercial sterilizers.

Measurement Challenges

Low-level detection of ethylene oxide has been complex for quadrupole mass spectrometry due to interfering species with identical molecular weights, such as CO₂, acetaldehyde, and propane, which might appear in the sample matrix.

EtO is highly reactive, particularly with acids, making it hard to gather a stable sample for the following analysis at a laboratory.

At sterilization facilities, scrubber systems can use aqueous acids to transform ethylene oxide to ethylene glycol. If any residual acid mists are present in the sample, some might be lost. EtO is hard to trap and concentrate due to its low boiling point. An analytical technology improved for real-time, direct measurement of EtO is essential to resolve such difficulties.

Solution

With novel Thermo Scientific™ StarBoost™ Technology, the Thermo Scientific™ MAX-iR™ FTIR Gas Analyzer could address such difficulties.

This optical improvement solution considerably increases the signal-to-noise ratio (SNR) of the MAX-iR Analyzer, offering minimum detection limits (MDLs) that are 50x lower compared to the other commercially available Fourier-transform infrared (FTIR) gas analyzers.

This can be done without the need for extremely long pathlength gas cells. Optically enhanced FTIR (OE-FTIR) technology enables the detection of <1 part-per-billion (ppb) EtO in real-time.

This MAX-iR Analyzer is known to be the basis of the fully automated Thermo Scientific™ EMS-10™ Continuous Emissions Monitoring System (CEMS), which consists of adaptable Thermo Scientific™ MAX-Acquisition™ Control Software and complies with United States Environmental Protection Agency (US EPA) CEMS standards.

A combination of field trials and laboratory performance studies illustrate how the EMS-10 System fulfills the application needs for an EtO CEMS.

Field trials were performed at a commercial sterilization facility in North America, where the EMS-10 System was utilized to continuously quantify EtO emissions from a common stack. US EPA ALT-142 approves OE-FTIR usage in lieu of gas chromatography (GC) for EtO emission testing at commercial sterilizers, which have been controlled under 40 CFR Part 63, Subpart O.)

All data were gathered utilizing the EMS-10 System configured with a StarBoost Technology and MAX-iR Analyzer. FTIR configuration details are explained in Table 1.

Table 1. MAX-iR Analyzer configuration details. Source: Thermo Fisher Scientific – Environmental and Process Monitoring Instruments

| . |

. |

| Detector |

InAs |

| Laser type |

VCSEL diode laser |

| Optical path length |

9.86 m |

| Gas cell volume |

0.4621 L |

| Pressure sensor |

1 atm |

| Gas cell windows |

CaF₂ |

| Gas cell O-rings |

Viton |

| Gas cell mirror material |

Nickel-plated aluminum with gold coating |

| StarBoost optical enhancement filter |

Long pass filter |

| Spectral range |

2900–3400 cm-1 |

Laboratory Performance Study

Materials

Table 2 explains the certified EtO standard utilized in the test protocol (discussed as the “reference gas”). This also contained ethane as a tracer for dynamic spike recovery studies. Ethylene was used as a calibration transfer standard (CTS) for routine pre-test QA/QC.

Table 2. Reference gas cylinder information. Source: Thermo Fisher Scientific – Environmental and Process Monitoring Instruments

| Cylinder ID |

Expiration date |

Gas |

Certified concentration |

Analytical uncertainty |

| CC736527 |

30 September, 2023 |

Ethylene oxide |

1223 ppb |

±10% |

| Ethane |

100.20 ppm |

±10% |

| CC512410 |

25 May, 2030 |

Ethylene |

97.78 ppm |

±1% |

The gas manufacturer has verified compositions by making use of direct comparisons to National Institute of Standards and Technology (NIST) traceable calibration standards and NIST gas-mixture reference materials.

To dilute the reference gas mixture and zero the MAX-iR Analyzer, ultra-high purity (UHP) nitrogen was utilized. Before the study, regular MAX-iR instrumental diagnostics and direct calibration checks were made to guarantee that the analyzer was working correctly.

Limit of Detection

A limit of detection (LOD) test illustrates the least amount of EtO to be detected above the background in a representative gas matrix. The EMS-10 System was fixed to sample ambient laboratory air at its target sample flow rate.

The EtO response was quantified for around 7–11 consecutive 1-min scans, and the LOD was specified as three times the standard deviation of these measurements. Results are displayed in Table 3.

Table 3. Ethylene oxide LOD results. Source: Thermo Fisher Scientific – Environmental and Process Monitoring Instruments

| |

Average |

Standard deviation (σ) |

LOD (3 σ) |

| Ethylene oxide (ppb) |

-0.3 |

0.2 |

0.6 |

Accuracy and Linearity

Accuracy and linearity of the EtO measurements were identified next to the emission standard concentration (this could also be executed for users’ specific, actionable level). An EtO reference gas was initiated into the MAX-iR Analyzer for direct measurement.

Image credit: Thermo Fisher Scientific

The reference gas was diluted in nitrogen to three target concentrations: a low (26.6 ppb), mid (51.9 ppb), and high (99 ppb) level. Each was quantified in triplicate for a total of nine measurements, thereby guaranteeing that the same gas concentration was not initiated twice in succession.

The percent error was assessed for each level as the difference between the anticipated reference concentration and the average measured concentration, divided by the span value (99 ppb).

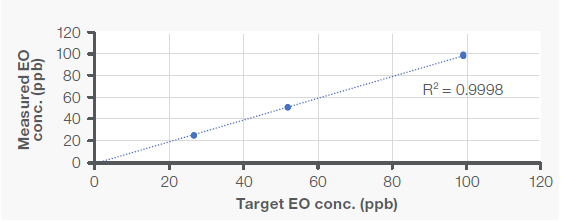

For linearity to be identified, the expected versus average quantified concentration was plotted to evaluate R2. For precision results, see Table 4. Linearity results are displayed in Figure 1.

Table 4. Ethylene oxide accuracy results. Source: Thermo Fisher Scientific – Environmental and Process Monitoring Instruments

| Level |

Replicate |

EtO concentration (ppb) |

Error (% of span) |

| |

|

Target |

Measured |

|

| Zero |

1 |

0.0 |

-1.1 |

~MDL |

| Low |

1 |

26.6 |

24.6 |

-1.95% |

| Mid |

1 |

51.9 |

50.5 |

-1.38% |

| High |

1 |

99.0 |

98.1 |

-0.93% |

| Zero |

2 |

0.0 |

-1.1 |

~MDL |

| High |

2 |

99.0 |

98.2 |

-0.76% |

| Mid |

2 |

51.9 |

50.7 |

-1.12% |

| Low |

2 |

26.6 |

24.8 |

-1.72% |

| Zero |

3 |

0.0 |

-0.6 |

~MDL |

| High |

3 |

99.0 |

99.4 |

0.35% |

| Low |

3 |

26.6 |

25.2 |

-1.40% |

| Mid |

3 |

51.9 |

51.0 |

-0.86% |

Figure 1. Ethylene oxide linearity results. Image Credit: Thermo Fisher Scientific – Environmental and Process Monitoring Instruments

Response Time

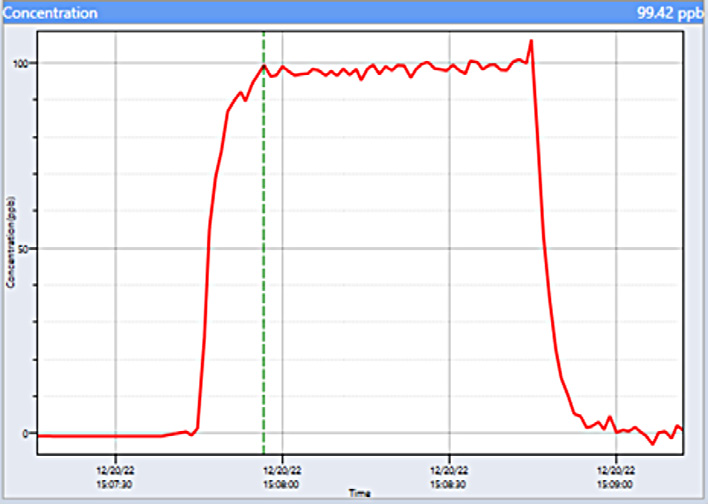

This test identifies the time it takes the EMS-10 System to react to a change in EtO concentration (operating usually at its target sample flow rate). The “zero” gas was initiated into the EMS-10 System at a flow rate that surpassed the sample pump flow.

EtO reference gas was initiated at the high level (99 ppb), and once the EtO response stabilized (that is, did not differ by over 1%), the time needed to obtain 95% of full scale (“rise time”) was quantified (12 seconds). Zero gas was reintroduced, and once the EtO response stabilized, the time needed to reach <5% of full scale (“fall time”) was measured (11 seconds) (Figure 2).

Figure 2. Ethylene oxide response time. Image Credit: Thermo Fisher Scientific – Environmental and Process Monitoring Instruments

Field Study

Field trials were performed at a commercial sterilization facility, where the EMS-10 System continuously quantified EtO emissions from a common stack, tracking US EPA ALT-142. A stainless-steel probe was inserted into the stack and fixed to a 100-ft sample line heated to 120 °C.

This sample line was linked to the EMS-10 System, which had a 120 °C diaphragm pump and heated particulate filter. An unheated exhaust line was associated with the outlet of the EMS-10 System to eliminate the sample from the test location.

After direct calibration checks and routine pre-test diagnostics, analyte spiking was executed to illustrate the accuracy and bias of the instrument, as per the US EPA Method 301.

This illustrated the affected transport of EtO via the EMS-10 System when the complete sampling train was challenged. EtO reference gas was spiked into the native stack emissions at 154 ppb (Tables 5 and 6).

Table 5. Analyte spike data for US EPA Method 301 Section 12. Source: Thermo Fisher Scientific – Environmental and Process Monitoring Instruments

| Test run |

Tracer (ppmv) |

Dilution factor |

Ethylene oxide (ppmv) |

Calculated spike level (ppmv) |

Percent recovery |

| |

Spiked |

Native |

|

Spiked |

Native |

|

|

| 1 |

29.188 |

0.013 |

0.061 |

0.136 |

0.028 |

0.146 |

92.7% |

| 2 |

29.306 |

0.059 |

0.061 |

0.138 |

0.036 |

0.151 |

91.1% |

| 3 |

29.273 |

0.041 |

0.061 |

0.140 |

0.034 |

0.148 |

94.1% |

| 4 |

29.386 |

0.056 |

0.061 |

0.138 |

0.041 |

0.155 |

88.6% |

| 5 |

29.365 |

0.047 |

0.061 |

0.142 |

0.038 |

0.153 |

92.8% |

| 6 |

29.404 |

0.087 |

0.061 |

0.143 |

0.030 |

0.146 |

98.1% |

| 7 |

29.392 |

0.048 |

0.061 |

0.144 |

0.042 |

0.157 |

91.7% |

| 8 |

29.439 |

0.068 |

0.061 |

0.143 |

0.043 |

0.157 |

90.8% |

| 9 |

29.373 |

0.048 |

0.061 |

0.146 |

0.044 |

0.158 |

92.5% |

| 10 |

29.416 |

0.076 |

0.061 |

0.147 |

0.042 |

0.156 |

94.2% |

| 11 |

29.422 |

0.051 |

0.061 |

0.142 |

0.045 |

0.159 |

89.3% |

| 12 |

29.425 |

0.099 |

0.061 |

0.148 |

0.045 |

0.159 |

93.1% |

| Mean |

29.366 |

0.058 |

0.061 |

0.142 |

0.039 |

0.154 |

92.4% |

Table 6. Statistical analysis for US EPA Method 301 Section 12. Source: Thermo Fisher Scientific – Environmental and Process Monitoring Instruments

| Bias analysis |

Value |

Criteria |

Validation |

| Relative bias, BR |

7.63% |

<10% |

PASS |

| Relative standard deviation, RSD |

2.82% |

<20% |

PASS |

Table 7. Summary of results. Source: Thermo Fisher Scientific – Environmental and Process Monitoring Instruments

| Test |

Measurement |

Result |

| Limit of detection |

3 σ |

0.6 ppb |

| Accuracy |

Avg. error (% of span) |

-1.08% |

| Linearity |

R² |

0.9998 |

| Response time |

Rise time

Fall time |

12 seconds

11 seconds |

| Spike recovery |

Avg. % recovery |

92.37% |

| US EPA Method 301 |

Relative bias

Precision (RSD) |

7.63%

2.82% |

Results and Conclusions

The EMS-10 System, configured with StarBoost Technology, perfectly tracks low-level EtO emissions from chemical manufacturing and commercial sterilization facilities.

Having a LOD below 1 ppb and responsivities of less than 15 seconds, the EMS-10 OE-FTIR System displayed excellent performance compared to the standard GC systems, which generally have a LOD of 50 ppb and an analysis time of ≥10 minutes.

Technology with lower detection limits avoids over-reporting emissions when stack concentrations are below 50 ppb.

The performance of the EMS-10 OE-FTIR System surpassed current US EPA standards for EtO, and the flexibility and sensitivity of the system made it simpler to adapt to shifting regulations, such as alterations to the National Emissions Standards for Ethylene Oxide Emission Standards and Hazardous Air Pollutants (NESHAP) for Sterilization Facilities (40 CFR Part 63, Subpart O).

This information has been sourced, reviewed and adapted from materials provided by Thermo Fisher Scientific – Environmental and Process Monitoring Instruments.

For more information on this source, please visit Thermo Fisher Scientific – Environmental and Process Monitoring Instruments.