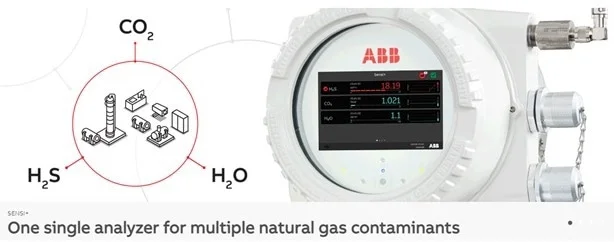

Sensi+, the GLA533-NG model from ABB, identifies various gas contaminants in natural gas at the same time. It delivers continuous H2S, H2O, and CO2 measurements for custody transfer, tariff compliance, and process monitoring.

A single, compact analyzer that uses ABB’s renowned laser-based technology to provide accurate measurement while allowing quick response time to process disturbances.

Image Credit: ABB Measurement & Analytics

Overview

The Next Generation Single Analyzer Solution for Multiple Natural Gas Contaminants

The Sensi+ GLA533-NG model is developed to measure natural gas contaminants such as H2S, H2O, and CO2. Real-time contamination level monitoring enables the activation of threshold alarms to reroute contaminated streams that might otherwise imperil the safety and operational yield.

Sensi+ has a simple and comprehensive user interface with AnalyzerExpertTM features that directly allow expert actions and insights from the device for better information and user experience.

Advantages of ICOS Technology

For over 15 years, ABB’s Integrated Cavity Output Spectroscopy (ICOS) laser absorption technology has been at the core of the world’s most reliable gas analyzers used for applications requiring highest overall performance. Advanced spectroscopic analyses provide highest accuracy, precision, sensitivity, and reliability.

Thanks to ICOS Technology, Sensi+ features:

- Rapid responsiveness to changes and rapid refreshment rate on measurement

- Internal performance metrics for asset health monitoring

- A high-resolution diode laser absorption technology and data analytics to reduce cross-interferences

- Low sample flow, reducing the environmental effect and economic loss due to gas venting

- Decreased ownership costs: the sample is measured directly without conditioning, and the design minimizes the consumption of consumables

- no need for periodic calibration

Image Credit: ABB Measurement & Analytics

Why Measure Contaminants in Natural Gas?

Excess levels of the target contaminants cause internal corrosion in natural gas infrastructure, particularly pipelines and storage facilities, and other mission-critical assets. As a result, measurements of these target gases are typically required in custody transfer requirements. Specific contaminants must be monitored due to regulatory requirements and tariff compliance.

Sensi+ is a solution for measuring three natural gas impurities concurrently and continuously in a single device.

Features and Benefits

Easy Installation and Commissioning for Hazardous Areas

The hazardous area compliant analyzer, with its flame-proof and dual-seal construction, requires only a simple wall mount installation and process tie-in, without a complex purging system.

With no field calibration required, a simple field validation is required before the analyzer is ready to produce rapid and reliable data.

Image Credit: ABB Measurement & Analytics

User Interface

Intuitive and Insightful User Interface on a Modern Software Platform

The analyzer has cutting-edge user interfaces for local and remote access, enabling quick and detailed information.

Local HMI

Sensi+ comes with a 7-inch screen and three LEDs for information and a gesture control system. For more detailed information, the local HMI provides different views:

- Alarms screen

- Measurement’s screen

- System information

- Diagnostics and advanced diagnostics

Gesture Control

The local HMI is a read-only interface, and navigation is accomplished using a gesture controller. The user can move between the various pages by passing their hand in front of the gesture detector located beneath the screen.

Image Credit: ABB Measurement & Analytics

Remote HMI

The remote HMI is a HTML-based user interface that delivers detailed information and settings without requiring proprietary software. The remote HMI offers numerous access points and menus, including:

- Measurement screen

- Alarms display, acknowledgment, and information

- Settings and configurations of gas parameters, physical interfaces, and general parameters

- Reports and export of historical data

- Process Events

- Systems information

Image Credit: ABB Measurement & Analytics

Maintenance and Reliability

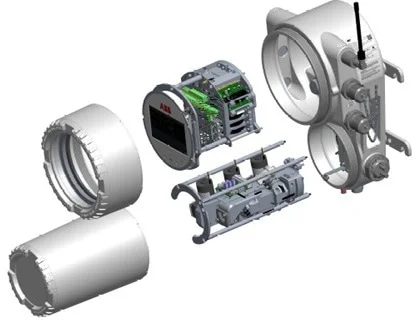

The Sensi+ features a modern design for convenient serviceability while maintaining a low maintenance schedule.

This analyzer was built from the ground up to be managed by people with little or no prior experience with spectroscopic devices.

Image Credit: ABB Measurement & Analytics

Both hardware and software offer low maintenance by utilizing easily changeable and field-accessible electro-mechanical components such as:

- Detector

- Filters

- Proportional valve assembly

- Pump Manifold

- Wetted path assembly

Software Maintenance Support Features

- Automated Pump health status validation

- Self-diagnostics

- AnalyzerExpert Features

- Direct access to user manual and service guides

Reliable Light Source

Light source replacement is no longer necessary, thanks to rugged laser technology. Near-infrared diode lasers used in ABB analyzers provide several years of stable continuous operation in various environmental conditions.