Anguil Environmental Systems was commissioned to provide an oxidizer and packed tower air stripper capable of treating a 65 gallon per minute water stream containing substantial concentrations of Volatile Organic Compounds (VOCs), Diesel Range Organics (DRO) and Total Suspended Solids (TSS).

The customer had initially sent the wastewater stream via a cooling tower, but this was repeatedly fouling from the DRO in the water. Each time the tower was brought out of service for cleaning, it resulted in significant maintenance costs and production downtime.

The customer was also working to achieve zero VOC emissions from their facility – an additional factor that had to be considered.

The Solution

Anguil’s application engineers explored these issues, initially determining that a Regenerative Thermal Oxidizer (RTO) would best meet the customer’s needs. The engineers were not convinced that the air stripper would work, however, due to the water characteristics outlined by the customer.

Anguil’s team evaluated the water stream for the air stripping application, with the analysis of the supplied water confirming that concentrations of the heavier Diesel Range Organics (naphthalene and higher) were present beyond their solubility limits.

The presence of this in the water stream would result in the rapid fouling of any air stripper, adversely affecting stripping performance and potentially creating a safety risk.

Anguil advised the customer to explore options around oil/water separation and emulsion breaking in order to remove and potentially recover the resellable product before this entered the air stripper.

The Result

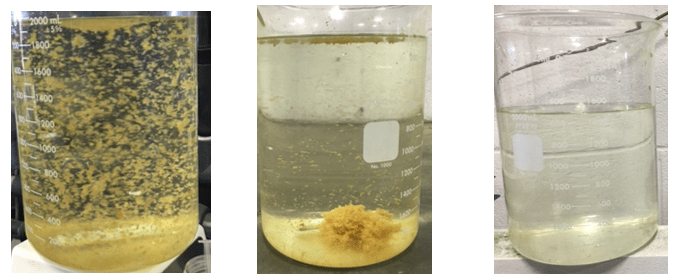

Water samples provided by the customer were used to conduct an initial bench evaluation of oil/water separation.

This evaluation did not reveal the presence of DRO, meaning that either the customer-supplied water analysis was erroneous, or the water samples received were not representative of the customer’s process water.

The emulsion breaking tests were performed, but as predicted, were unsuccessful. Anguil also attempted to coagulate the water to determine the suitability of this approach, revealing that this method had potential.

Results of the initial separation study prompted Anguil to advise two courses of action.

The customer would be required to redo their water analysis using the recommended test methods, improving confidence in the treatment design requirements. Then, based on the second round of analytical tests, a two-stage pilot study should be conducted.

Stage 1 of this pilot study would see Anguil representatives conducting onsite treatability studies. Results would then be employed as part of a full-scale, onsite pilot with the appropriate equipment (Stage 2).

The Pilot Study

Stage 1

Representatives from Anguil performed onsite jar tests directly using the process water.

The process water’s temperature was typically between 110 °F and 120 °F, so it was deemed advantageous to engage with the process directly, rather than shipping samples off-site and risking any compromise in sample integrity due to biological action, cooling or chemical reactions.

Several trials were conducted, revealing that the water could be coagulated by raising the pH from 4 to 8.5. This was achieved utilizing a poly aluminum chloride (PAC) based coagulant blend and a standard polymer.

Turbidity, color and solids content were notably reduced following coagulation and filtration.

Both untreated and treated water was sent away for third party lab analysis to evaluate the overall effectiveness of the process. This revealed promising results, prompting the customer to move forward with Stage 2 of the pilot study.

Image Credit: Anguil Environmental Systems

Stage 2

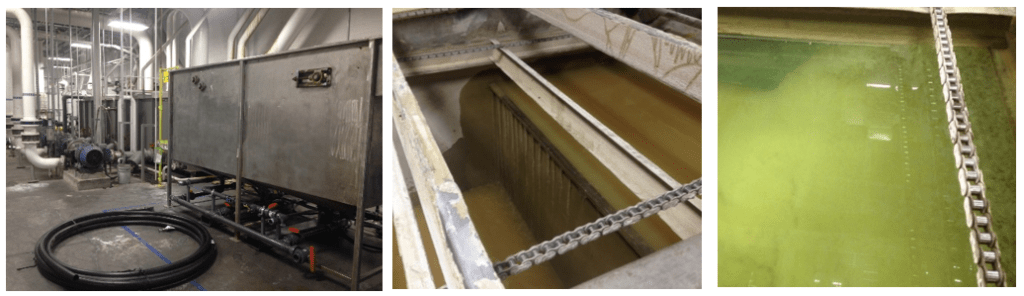

Anguil modified its pilot clarification system based on the treatment goals and site constraints, enabling the commencement of the second stage of the study.

Once the equipment had arrived on site, it was unloaded and placed within the facility. A generator was employed since the facility was unable to ensure the required power would be available. With this in place, the pilot system was unpacked and plumbed into the existing process piping.

Image Credit: Anguil Environmental Systems

Pilot System

With equipment in place and pumps primed and running, operators filled the tank with process water and started the processing using the chemical formula established in Stage 1 (raise pH > 8.5 using 50% caustic solution, add 300 ppm coagulant, add 1 ppm polymer).

As anticipated, the clarifier influent exhibited floc which quickly started to settle at the bottom of the clarification tank. Continued processing resulted in further, more obvious clarity improvements in the clarification tank.

Submerged sections of the tank started to become visible as the dirty water was gradually displaced by the coagulated and clarified water.

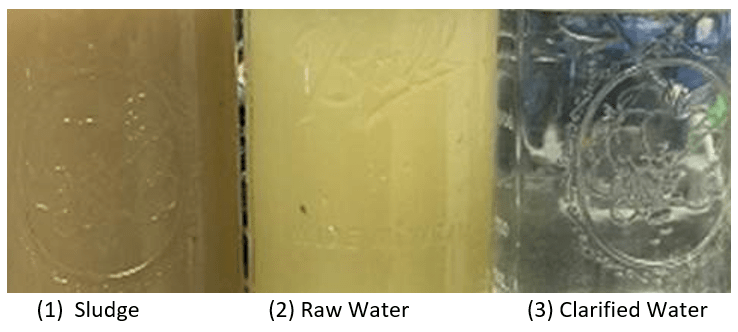

Water samples obtained from the clarifier effluent were clearly cleaner than the initial raw process water, and acceptable levels of clarity were achieved via continued processing.

Once the effectiveness of the clarification process had been confirmed, treated samples were acquired and tested using the test protocol employed in Stage 1.

A sludge sample was also sent for benzene analysis to ascertain any risks from the sludge and determine whether this should be considered hazardous.

Sludge production rates were quantified by coagulating, flocculating and then filtering defined volumes of process water. Filtered samples were wrung dry before being air dried for a number of days, and both wet and dried samples were weighed.

Image Credit: Anguil Environmental Systems

Pilot Test Results

Qualitative and quantitative results from these measurements were in line with the customer’s expectations and treatment goals. The chemical coagulation protocol and clarifier employed in the pilot achieved an 85% or greater DRO reduction alongside an 80% reduction in TSS.

Anguil recommended using a ballasted floc system in the final treatment system to accommodate the design flow rate of 65 GPM.

Therefore, an additional set of samples was acquired for ballasted floc testing, achieving similar DRO removal rates while improving TSS reduction to under 1 NTU.

The customer asked Anguil to recommend a sludge dewatering system in response to a review of sludge production rates and its classification as potentially hazardous.

Once the treatment system capabilities and facility requirements had been reviewed, Anguil also advised removing the air stripper and oxidizer from the scope of supply.

Removing the heaviest organics was deemed a solution to the facility’s heat exchanger fouling issues, while the limited VOC loading did not warrant the use of an oxidizer.

Anguil guided the customer through the equipment design and selection process by identifying and rectifying shortcomings in the analytical data, avoiding time and cost specifying and designing equipment that would not address the customer’s project goals.

Choosing to commission Anguil for this project resulted in a solution that successfully met the customer’s objectives, despite the selected solution being very different from the initial request.

Onsite jar and pilot tests helped educate the customer, allowing them to become more familiar with the treatment process and facilitating an appreciation of the proposed system’s benefits, capabilities and trade-offs.

Working closely with the customer onsite allowed Anguil to explore and comprehend the customer’s requirements and process thoroughly.

The customer’s process variables were identified, and any factors potentially impacting treatment system performance could be managed. This enabled the seamless integration of the new treatment system into the existing process.

This information has been sourced, reviewed and adapted from materials provided by Anguil Environmental Systems.

For more information on this source, please visit Anguil Environmental Systems.