Walnut shell abrasives are used extensively in processes such as blasting, cleaning, cosmetics, filtration, polishing and tumbling, as well as non-skid and filler applications. Walnut shells are pulverized, ground and categorized to standard particle sizes that extend from coarse grit to fine powders.

There are two types of ground Walnut Shells produced: standard-grade English Walnut Shells (juglans regia) and filtration-grade Black Walnut Shells (juglans negra).

This article highlights the applications and uses of walnut shells.

Characteristics of Crushed Walnut Shells

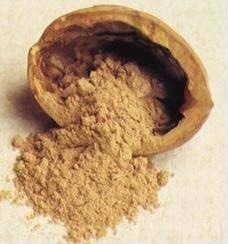

Walnut shell media (Figure 1) is an all-natural, biodegradable, long-lasting material with exceptional strength properties. Its specific gravity ranges between just 1.2-1.4 and has hardness levels of 3.5 MOH and 91 Rockwell.

Figure 1. Walnut shell blasting media. Image Credit: Composition Materials

Walnut Shell Blasting

In walnut shell blasting, air blast or wheel blast equipment is employed to remove paints and coatings from buildings, boats, cars, furniture, fiberglass, steel, etc. As an environmentally friendly material, Walnut shells are often utilized in outdoor blasting applications.

Walnut shell blasting can remove coatings and paints without damaging substrates. Under certain blast parameters, blasting with walnut shells can facilitate selective coating removal in which the top coating is removed without impacting the underlying coatings.

In blast operations, walnut shells can offer economacal advantages by reclaiming and reusing media for numerous blast cycles. When blast cleaning, various factors need to be considered including media particle size, nozzle distance, p.s.i. and safety. Walnut shell blasting is also an excellent alternative to sandblasting.

Walnut Shells for Deflashing, Polishing and Tumbling

Walnut shells are utilized for deflashing and cleaning parts, as well as for tumbling and polishing. In tumbling applications, a polishing compound is often introduced into the walnut shell mix.

Walnut Shell Fillers

Ground walnut shell flours are utilized as fillers in the construction, adhesive, furniture, paint, plywood, paint, resin, rubber and cosmetic industries. In manufacturing, walnut shell flour can be used as an all-natural additive.

Additionally, walnut shells are used in burn-out applications to enhance ceramic porosity and as a non-skid additive for stairs, floors, decks, pools and ramps.

Figure 2. Walnut shell flour. Image Credit: Composition Materials

Walnut Shell for Filtration

The Black Walnut variety (juglans negra) has an extremely hard shell with characteristics that make it an ideal media in filtration operations. For example, Black Walnut Shells offer excellent filtration solutions in oil fields for separating oil or solids from water.

Figure 3. Black walnut shell filtration media. Image Credit: Composition Materials

Walnut Shells in Cosmetics

Walnut shells can be used in a range of bath and body products, hand soaps and scrubs. This all-natural, biodegradable ingredient is a superb alternative to microbeads and has been utilized in cosmetic formulations for more than 30 years.

This information has been sourced, reviewed and adapted from materials provided by Composition Materials.

For more information on this source, please visit Composition Materials.