In this interview, Milan Milosevic, the President of Durasens LLC, talks to AZoCleanTech about monitoring flocculation with the Jar FlocCAM® and Basin FlocCAM®.

What are the Jar FlocCAM® and Basin FlocCAM®, what do they do, and how?

The JarFlocCAM® and Basin FlocCAM® are devices developed to monitor flocculation. The Jar FlocCAM® monitors flocculation during jar tests and the Basin FlocCAM® in the flocculation basin. The Jar FlocCAM® mounts directly onto a standard square 2-liter jar. The Basin FlocCAM® mounts on a fence surrounding the basin.

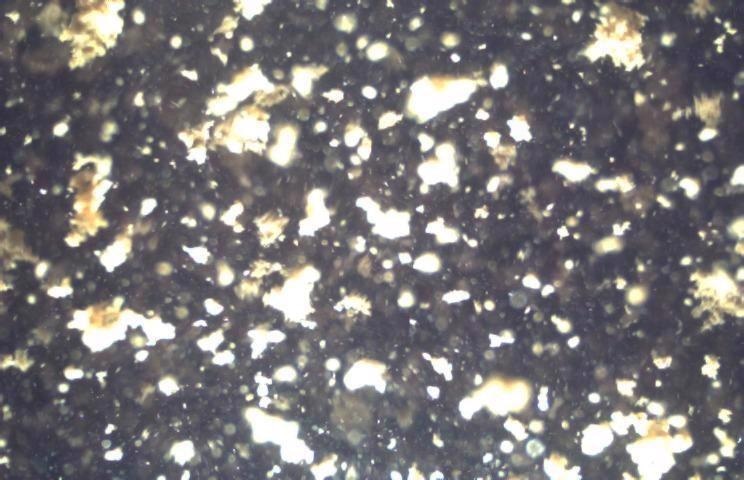

The technology behind these devices is based on image analysis. The FlocCAM®s take continuous real-time images of the flocs in situ. These live images are analyzed in real-time. Individual flocs are identified, the size and shape of every floc particle are determined, and a number of parameters quantifying their size and shape are determined. In addition, the distribution of flocs by size in each image is found, and a number of parameters characterizing this distribution are determined.

An image can be analyzed as often as one every second. The parameters are typically averaged using the user selected running N point average to reduce the statistical noise. These averaged values are stored locally in a CSV file and can be further analyzed using Microsoft Excel or similar software.

Image credit: Durasens

Why do water treatment plants need to monitor their flocculation process?

The principal task of every water plant is to remove the suspended solid matter and particulates from water. The suspended microscopically small particles called flocs have a roughly equal specific gravity as the water, so they freely levitate in the water column. An electric charge that builds up on these particles is generally of the same polarity, so these particles repel each other, which prevents them from colliding and sticking together. The first step in the treatment is to add chemicals that neutralize the charges on the particles and allow them to collide and stick together, forming larger flocs. To promote the collisions of these small particles, the water is mixed. Once flocs grow bigger, the water is transferred to the sedimentation tanks, where flocs can settle to the bottom of the tank. In this way, most of the solid matter is removed from the water. Only the tiniest particles remain suspended. In the last step, the water is filtered to remove these remaining particles.

The importance of the flocculation is that the more optimized it is, the more solid matter is removed, and less is left for removal by filtering. If flocculation is suboptimal, the filters have to remove more and become clogged quicker. Filters can be cleaned by the process known as backwashing, but the more often the filters need to be backwashed, the less efficient the plant. It is using more energy and producing less water.

How does monitoring the flocculation process benefit water treatment plants?

The flocculation process requires chemicals to be added to water, and it uses electricity to backwash the filters. Both operations are expensive to the plant. Chemicals have to be purchased, and the sludge formed by the sedimented flocs has to be removed and disposed of as chemical waste, since it contains the flocculation chemicals. Optimizing the flocculation prevents overdosing with chemicals, reducing the expense of purchasing the chemicals and reducing the amount of chemical waste that requires costly disposal. In addition, the optimal flocculation reduces the amount of matter that has to be removed by the filters, thus reducing the plant's use of energy and simultaneously increasing the water output.

What are the environmental benefits of optimized flocculation?

As mentioned above, water treatment requires energy, consumes chemicals, and as a byproduct, it generates chemical waste. Aside from benefiting the economy of water treatment plants, optimal flocculation reduces the amount of energy necessary for the treatment, therefore benefiting the environment by reducing the overall electricity demand. The amount of electrical energy saved by a single plant may seem trivial and inconsequential to the overall demand, but when multiplied by the number of water treatment plants (every municipality has or shares a water treatment plant), it becomes significant.

Similarly, the amount of chemical waste from a single plant may not be that significant, but the amount of waste from all the plants in the US is definitely substantial.

How is Jar FlocCAM® used in water research?

Water research is an active area of environmental science. Theoretical and experimental work to better understand the different steps in water treatment is being constantly pursued. The various theories of the flocculation process aim to account for the effects of various conditions that affect it. It is known that water quality, temperature, pH, etc., have a significant impact on the treatment process. It is also well known that rain, wind, solar irradiation, etc., can hugely disturb a plant's operation. With most of these environmental factors, there is little a plant can do, but predicting the nature of the impact and applying timely corrective actions such as selecting different coagulation chemicals, adjusting their dosing, adjusting their mixing speed, etc., can minimize disturbances.

It is not practical to run experiments in a working plant, so researchers can use the jar test to mimic what is occurring in the flocculation basin. These tests are standard tools in water treatment plants to help them decide how to adjust their process in response to seasonal and other changes in raw water. Traditionally, these tests are run concurrently in multiple jars with different doses of chemicals, and the resulting floc particles are observed by the eye to determine which dose appears optimal. No quantitative parameters are provided for comparison with past (or future) tests. Quantification of the flocculation process provided by the Jar FlocCAM® offers substantial enhancement to the standard jar test, both for the water treatment plants and for the research community. In addition to quantifying the end result of the test, the Jar FlocCAM® provides quantification of the entire flocculation process enabling researchers to assess the effects of various parameters on the dynamics of the reaction. This improved understanding developed by academic researchers can then be utilized by water treatment plants to help them optimize their process.

About Durasens

Durasens manufactures and sells FlocCAM®s , instruments that take the guesswork out of evaluating floc quality in water treatment plants. The Basin FlocCAM® monitors flocs in flocculation tanks, and the Jar FlocCAM® monitors floc particles’ formation during a jar test.

About Milan Milosevic

Milan Milosevic is President of Durasens LLC which makes equipment for water and wastewater treatment plants in addition to analytical instrumentation for process control plants.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.