Jul 6 2017

Experts at Rutgers University-New Brunswick and Michigan State University have worked on making it almost possible for biofuels such as ethanol in U.S. gasoline to become cheaper.

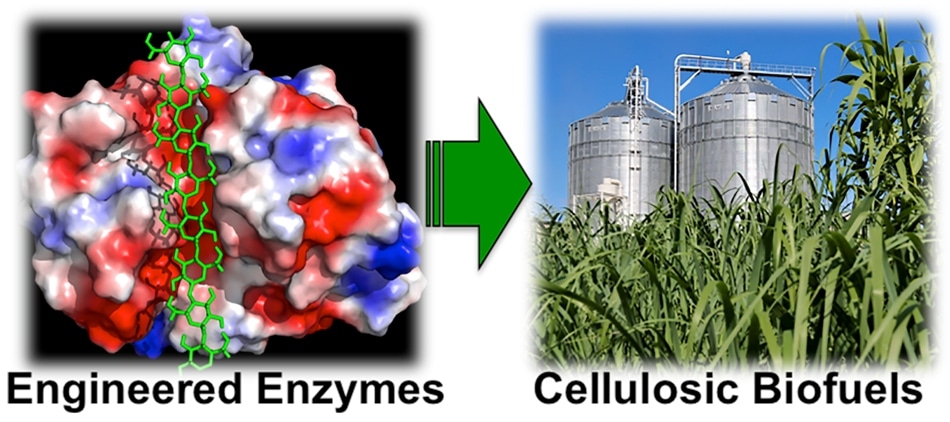

Photo: Enzymes, genetically engineered to avoid sticking to the surfaces of biomass such as corn stalks, may lower costs in the production of cellulose-based biofuels like ethanol. Shishir Chundawat/Rutgers University and U.S. Department of Energy

Photo: Enzymes, genetically engineered to avoid sticking to the surfaces of biomass such as corn stalks, may lower costs in the production of cellulose-based biofuels like ethanol. Shishir Chundawat/Rutgers University and U.S. Department of Energy

These Researchers have showed how to genetically engineer and design enzyme surfaces such that they bind less to corn stalks and various other cellulosic biomass, decreasing enzyme costs in biofuels production, according to a study featured this month on the cover of ACS Sustainable Chemistry & Engineering.

The bottom line is we can cut down the cost of converting biomass into biofuels.

Shishir P. S. Chundawat, Senior Author of the Study and an Assistant Professor, The Department of Chemical and Biochemical Engineering, Rutgers University-New Brunswick

Chundawat, whose department is in the School of Engineering, stated that the enzymes tapped to assist in turning switchgrass, corn stover (leaves, corn stalks and other leftovers) and poplar into biofuels at almost 20% of production costs. Enzymes cost about 50 cents for a single gallon of ethanol, thus using fewer enzymes or recycling them could make biofuels more cost-effective.

Gasoline, in the United States, generally comprises of up to 10% ethanol and corn grain is considered to be the primary feedstock of ethanol, according to the U.S. Energy Information Administration. About 15 billion gallons of ethanol are produced each year by biorefineries.

Chundawat said that, over the past few years, some refineries started to transform the inedible parts of corn plants into ethanol.

The challenge is breaking down cellulose (plant) material, using enzymes, into sugars that can be fermented into ethanol. So any advances on making the enzyme processing step cheaper will make the cost of biofuel cheaper. This is a fairly intractable problem that requires you to attack it from various perspectives, so it does take time.

Shishir P. S. Chundawat, Senior Author of the Study and an Assistant Professor, The Department of Chemical and Biochemical Engineering, Rutgers University-New Brunswick

Biomass comprises of lignin, which is an organic polymer capable of binding to and strengthening plant fibers. However, lignin inactivates enzymes that fasten to it, hindering efforts to decrease the cost and use of enzymes, according to Chundawat.

The Rutgers and Michigan State University Researchers have demonstrated how custom designed enzymes (proteins) have the potential to restrict their binding to and inactivation by lignin. This indeed will eventually reduce enzyme use and make enzyme recycling possible for biorefineries in the coming years, Chundawat said.

Other Authors of the study are Chandra K. Bandi, a Doctoral Student in Rutgers’ Department of Chemical and Biochemical Engineering; Marissa Berger, an Undergraduate Student in Rutgers’ Department of Biomedical Engineering; and Jihyun Park, a former Undergraduate Student in Rutgers’ Department of Chemical and Biochemical Engineering. The National Science Foundation largely supports Professor Chundawat’s current research on engineering enzymes for enabling low-cost biofuel production.