Apr 17 2018

Scientists at the National Institute of Standards and Technology (NIST) have created a nanoscale coating for solar cells that enable the absorption of around 20% more sunlight when compared to uncoated devices. They achieved this by trapping light with the help of an optical version of a whispering gallery. The coating was applied with the help of a method that can also be used in manufacturing and has opened the door for the development of highly efficient and inexpensive solar cells with renewable, abundant, and eco-friendly materials.

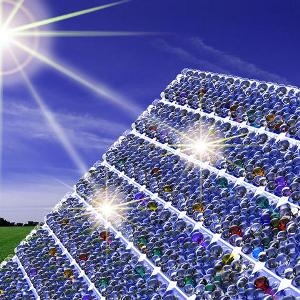

The illustration shows the nanoresonator coating, consisting of thousands of tiny glass beads, deposited on solar cells. The coating enhances both the absorption of sunlight and the amount of current produced by the solar cells. (Image credit: K. Dill, D. Ha, G. Holland/NIST)

The illustration shows the nanoresonator coating, consisting of thousands of tiny glass beads, deposited on solar cells. The coating enhances both the absorption of sunlight and the amount of current produced by the solar cells. (Image credit: K. Dill, D. Ha, G. Holland/NIST)

The coating comprises of thousands of tiny glass beads that have a width of just around one-hundredth of the width of a strand of human hair. When the coating is hit by sunlight, the light waves get steered around the nanoscale bead, similar to the movement of sound waves around a curved wall, for instance, around the dome in St. Paul’s Cathedral in London. Such curved structures are called acoustic whispering galleries. A person standing close to one part of the wall in these structures can easily hear the faint sound emerging from any other part of the wall.

Although whispering galleries for light were created nearly 10 years ago, scientists have only recently investigated their use in solar-cell coatings. In this research performed by a team including Dongheon Ha from NIST and the University of Maryland’s NanoCenter, the light absorbed by the nanoresonator coating ultimately leaks out and is then absorbed by an underlying solar cell formed of gallium arsenide.

The team used a laser as a light source to excite individual nanoresonators in the coating and discovered that the coated solar cells absorbed about 20% more visible light than bare cells. The measurements also showed that the coated cells generated 20% more current on average.

According to Ha, this is the first research that has demonstrated the efficiency of the coatings with the help of precision nanoscale measurements. “Although calculations had suggested the coatings would enhance the solar cells, we could not prove this was the case until we had developed the nanoscale measurement technologies that were needed,” he added.

Ha, collaborator Yohan Yoon from NIST and Maryland’s NanoCenter and NIST physicist Nikolai Zhitenev have reported the research in the latest issue of the Nanotechnology journal.

The researchers have also developed a rapid, inexpensive technique for applying the nanoresonator coating. Earlier, scientists coated semiconductor material by dipping it in a nanoresonator solution tub. This process was not only time-consuming but unnecessarily coated both sides of the semiconductor material, although only one side needed the treatment.

In the technique developed by the researchers of this study, droplets of the nanoresonator solution were placed on only one side of the solar cell. A coating made of closely packed nanoresonators was formed by pulling a wire-wound metal rod across the solar cell and then spreading out the solution. This is the first time that the team has applied the rod technique, which had been in use for more than 100 years to coat material in a factory setting, to a gallium arsenide solar cell.

“This is an inexpensive process and is compatible with mass production,” stated Ha.