Jul 27 2018

Precious metals, though limited in supply, are great in demand. While they are chiefly sourced through mining, there is growing interest in the possibility of recycling them from metallurgical waste leachates (waters that have moved via the treated materials during mineral processing and therefore contain some of the compounds that are present in the minerals).

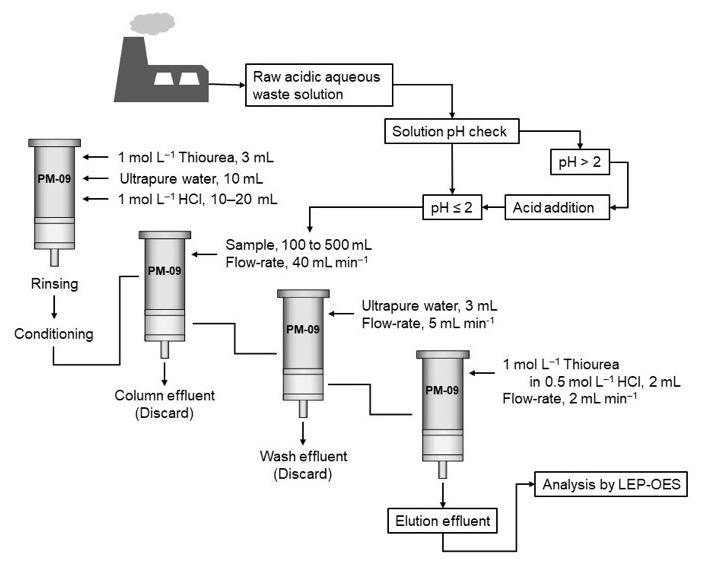

Operating protocol for the on-site analysis of precious metals using LEP-OES coupled with SPE-assisted selective preconcentration. (Image credit: Kanzawa University)

Operating protocol for the on-site analysis of precious metals using LEP-OES coupled with SPE-assisted selective preconcentration. (Image credit: Kanzawa University)

As a result, compact and moveable instruments to carry out the analysis of wastewaters in on-field rapid analysis are extremely preferred to enhance the efficiency of the recovery of valuable metals.

Liquid-electrode plasma-optical emission spectrometry, or LEP-OES, has evolved as a tool to perform on-site analysis of elements in aqueous matrices, as it is portable and much less expensive in comparison to conventional methods. On the other hand, if the concentration of noble metals is extremely low, as is the case for precious metals found in waste spills, the technique may not be sensitive enough to give accurate analysis - one of the drawbacks is that metallurgical waste leachates contain numerous ions that impede the analysis.

Here, for accurate detection of the precious metals, it is essential to incorporate analyte separation and enrichment steps (that is, steps that make detection easier by eliminating other substances and increasing the concentration of the analyte) in the analysis of the samples.

This is what Suman Barua, Hiroshi Hasegawa, Ismail M.M. Rahman and coworkers from Fukushima University and Kanazawa University did, reporting the initial application of LEP-OES together with a solid-phase extraction (SPE) system (which is used as the pre-treatment step to remove the competing ions, thus enriching the noble metals) for the quick on-site concurrent analysis of the precious metals such as platinum, palladium, and gold.

In order to maximize retention and recovery of the precious metals, the SPE parameters were optimized; to maximize the emission peaks for the individual elements, the LEP-OES parameters were optimized. The technique was tested on certified reference material for wastewater as well as on actual aqueous waste samples, from which over 95% of the precious metals were recovered. It takes less than 15 minutes to perform the high-precision on-site measurements, paving the way to practical examination of the precious metal content of wastewaters.