Feb 13 2019

Artificial leaves imitate photosynthesis—the process in which plants produce carbohydrates using water, carbon dioxide from the air, and energy from the sun. However, even the modern artificial leaves, which have the potential in minimizing carbon dioxide from the atmosphere, function only in the laboratory as they use clean, pressurized carbon dioxide from tanks.

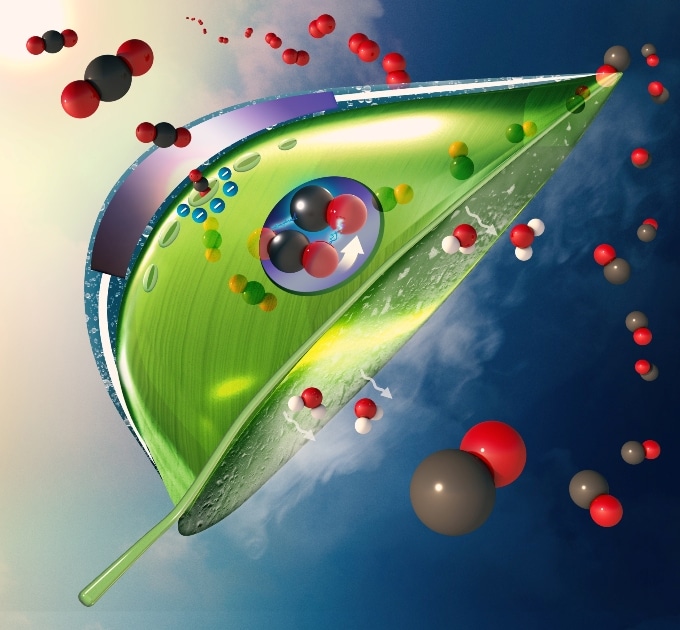

An artificial, bio-inspired leaf. Carbon dioxide (red and black balls) enter the leaf as water (white and red balls) evaporates from the bottom of the leaf. An artificial photosystem (purple circle at the center of the leaf) made of a light absorber coated with catalysts converts carbon dioxide to carbon monoxide and converts water to oxygen (shown as double red balls) using sunlight. (Image credit: Meenesh Singh).

An artificial, bio-inspired leaf. Carbon dioxide (red and black balls) enter the leaf as water (white and red balls) evaporates from the bottom of the leaf. An artificial photosystem (purple circle at the center of the leaf) made of a light absorber coated with catalysts converts carbon dioxide to carbon monoxide and converts water to oxygen (shown as double red balls) using sunlight. (Image credit: Meenesh Singh).

Currently, scientists from the University of Illinois at Chicago have suggested a design solution that could allow artificial leaves to work outside the lab and in the environment. Their enhanced leaf, which would use carbon dioxide—a strong greenhouse gas—from the air, would be nearly 10 times more efficient at converting carbon dioxide to fuel when compared to natural leaves. Their findings are published in the journal ACS Sustainable Chemistry & Engineering.

So far, all designs for artificial leaves that have been tested in the lab use carbon dioxide from pressurized tanks. In order to implement successfully in the real world, these devices need to be able to draw carbon dioxide from much more dilute sources, such as air and flue gas, which is the gas given off by coal-burning power plants.

Meenesh Singh, Assistant Professor, Department of Chemical Engineering, UIC College of Engineering.

Meenesh Singh is also the corresponding author of the paper.

If the pressurized carbon dioxide supply is cut off from these leaves, they should have another means to gather and concentrate carbon dioxide from the air to trigger their artificial photosynthetic reactions.

Singh and his colleague Aditya Prajapati, a graduate student in his lab, suggested to find a solution to this issue by encasing the conventional artificial leaf inside a transparent capsule composed of a semi-permeable membrane of quaternary ammonium resin filled with water. The membrane permits water from inside to evaporate out as it gets heated by sunlight. As water evaporates out through the membrane, it selectively draws carbon dioxide from the air. The artificial photosynthetic unit within the capsule is composed of a light absorber coated with catalysts that turn the carbon dioxide into carbon monoxide, which can be tapped and used as a source for producing different synthetic fuels. In addition, oxygen is produced and can either be collected or released into the adjacent environment.

“By enveloping traditional artificial leaf technology inside this specialized membrane, the whole unit is able to function outside, like a natural leaf,” Singh said.

As per their calculations, 360 leaves, each with a length of 1.7 m and a width of 0.2 m wide, would generate nearly half-ton of carbon monoxide per day that could be employed as the source for synthetic fuels. With 360 artificial leaves covering an area of 500 m2, it would be possible to achieve a 10% reduction in carbon dioxide in the surrounding air within 100 m of the array in a single day.

Our conceptual design uses readily available materials and technology, that when combined can produce an artificial leaf that is ready to be deployed outside the lab where it can play a significant role in reducing greenhouse gases in the atmosphere.

Meenesh Singh, Assistant Professor, Department of Chemical Engineering, UIC College of Engineering.

This research was carried out at UIC’s Materials and Systems Engineering Laboratory. The chemical engineering department offered financial support to carry out this work. A part of the funding was offered via UIC’s provost graduate research award.