As the world’s reliance on electronics grows, the search for viable solutions to recycle them intensifies. However, electronics can contain a variety of metals that are difficult to separate for proper recycling. Scientists have discovered that spent brewer’s yeast, a byproduct of beer production and the base for Marmite, can be used several times to extract metals such as aluminum, zinc, and copper from a solution.

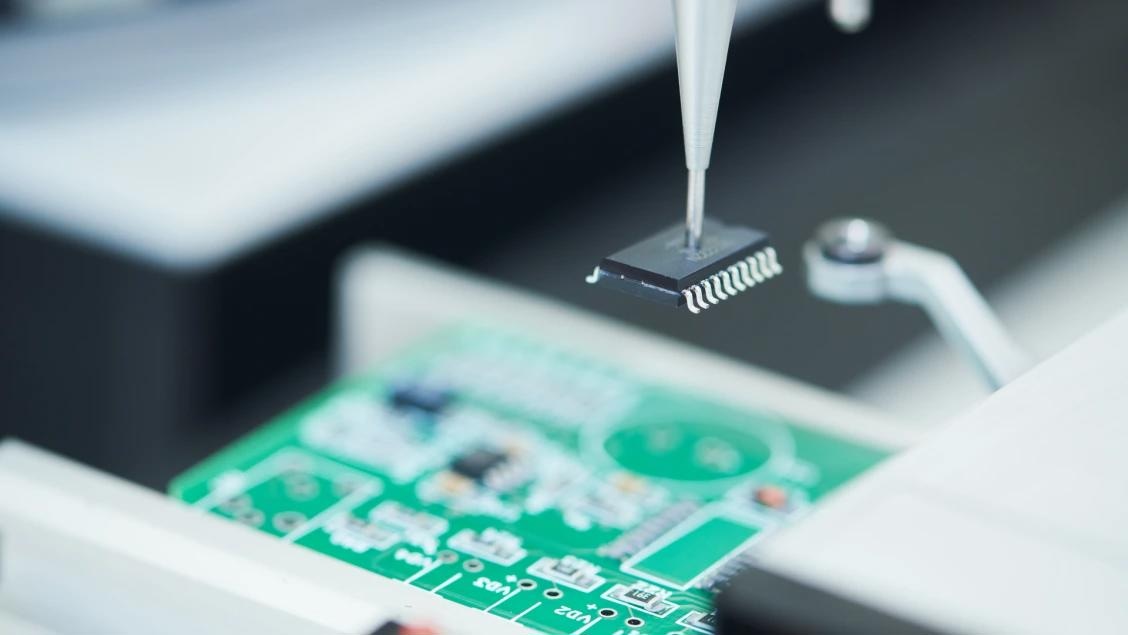

A robot installs a chip on a printed circuit board. Printed circuit boards and other electronics contain many different metals which are difficult to separate out for recycling purposes. Image Credit: Frontiers

A robot installs a chip on a printed circuit board. Printed circuit boards and other electronics contain many different metals which are difficult to separate out for recycling purposes. Image Credit: Frontiers

When the process was tested on a polymetallic waste stream, more than half of the copper and 90% of the zinc recovered.

When electronic equipment that can no longer be utilized is recycled, the rare natural materials used to produce them are expected to be used to their full potential. However, electronic debris is notoriously difficult to recycle due to the difficulty of separating the various metals in the waste.

Scientists have discovered a method of selectively extracting metals from a waste stream by utilizing spent brewer’s yeast, the same beer byproduct that goes into Marmite. Furthermore, the yeast can be reused, making the procedure even more environmentally beneficial.

Electronic waste is difficult to recycle because it is very heterogeneous. Getting the metals in solution is a first step, but the selective recovery of the metals remains a challenge. Compared to processes such as chemical precipitation, biosorption using spent brewer’s yeast presents a cheap and environmentally friendly approach.

Dr. Klemens Kremser, Study Corresponding Author and Postdoctoral Researcher, University of Natural Resources and Life Sciences

There are plenty of ways to separate the various metal components of electronic waste, including the use of additional biosorbents, or biological materials that can absorb pollutants. They all have serious drawbacks, though. For example, polluted slag is produced by chemical precipitation, and biochar, a charcoal-like biosorbent, is challenging to remove from wastewater.

So, the scientists used brewer’s yeast. Since spent brewer’s yeast is a typical byproduct of beer production, it is inexpensive and readily available. COMET (Competence Center for Excellent Technologies), Austria’s competence center program, provided funding for this study.

The scientists collected 20 liters of spent brewer’s yeast, isolated the biomass from the remaining brewing residue, and dried the biomass. Electrostatic interactions on the yeast’s surface allow metal ions to adhere to it, a process known as sorption. Changing the pH of this solution affects the interactions, allowing the yeast to adsorb more or different metal ions, depending on the solution’s composition and pH.

The scientists selected to test yeast biomass against commercially essential metals such as zinc, aluminum, copper, and nickel. The scientists evaluated each metal solution at various pH and temperature levels to determine whether it was feasible to strengthen the interactions and extract additional metal. The scientists additionally placed the yeast against an actual polymetallic waste stream.

Using waste biomass for metal recovery is not a completely new process, but the selectivity of biosorption processes is a key factor for efficient metal recovery from polymetallic waste streams. We demonstrated high metal recovery rates from a complex metal solution using an environmentally friendly and cheap biomass. Yeast biomass is considered a safe organism, and the demonstrated reusability of the biomass makes it an economically feasible approach.

Anna Sieber, Study First Author and PhD Fellow, K1-MET

Reduce, Reuse, Recycle

From the test metal solutions, the scientists were able to extract more than 50% of aluminum, more than 40% of copper, and more than 70% of zinc. They recovered more than 50% of copper and more than 90% of zinc from the polymetallic waste stream where the yeast was tested.

Temperature changes had little effect on efficiency, with the exception of zinc, where they increased the recovery rate by 7.6%. Similar to this, changing the pH had no impact on most of the metal solutions—except aluminum, where it increased recovery efficiency by 16%.

Sieber added, “The metals can be removed from the yeast surface by acid treatment and thus could be recycled.”

The scientists were able to recycle the yeast itself five times to recover various metals without significantly affecting its capacity to do so.

However, before the metal recovery technique is put into practice on an industrial scale, the scientists warn that significantly more research in real-world settings is needed to evaluate it.

Kremser concluded, “The metal removal process in this study was optimized for the four metals in question. The metal removal process in this study was optimized for the four metals in question.”

Journal Reference:

Sieber, A., et. al. (2024) Spent brewer’s yeast as a selective biosorbent for metal recovery from polymetallic waste streams. Frontiers in Bioengineering and Biotechnology. doi:10.3389/fbioe.2024.1345112