The growing demand for renewable energies has called for the optimization of the energy produced by wind farms. This is due to the low emission of greenhouse gases and the cleanliness of wind energy.

Bellat, A. et al. recently published a journal paper looking at using modeling to optimize existing wind farm designs. Their research is looked at throughout this article.

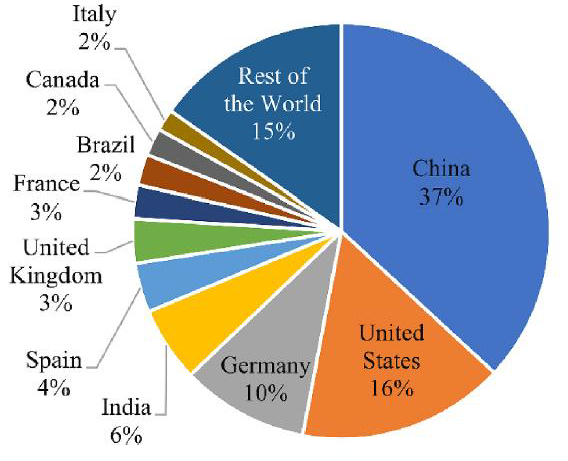

Figure 1 shows the power production by country, illustrating that China is the largest producer of wind power. The International Energy Agency has been making a lot of efforts to meet the global needs of 18% by 2050.

Figure 1. Wind energy produced by country. Image Credit: Bellat, A et al.

Designing a wind farm is challenging in that it involves choosing an appropriate location of one wind turbine relative to the other, mainly due to the interference of wakes generated by upstream wind turbines.

Such interferences and their strong dependence on installation site variables and design parameters affect the performance of wind farms as well as the entire viability of the wind project. Therefore, it is crucial to use rational methods such as heuristic optimization methods to solve this problem.

Optimizing the design of existing wind farms should involve maximizing the energy and minimizing the cost of a wind farm. It is often recommended to “repower” or “decommission” old wind farms.

The redevelopment of an existing wind farm involves changing a few parts or even a turbine. In the event that the “repowering” method is delicate, the wind farm is decommissioned, consequently leading to the shutdown of electricity production.

This article discusses the use of wind farm modeling to optimize the design of existing wind farms.

Methodology

Wind Farm Modeling

The wake downstream of the wind turbines is characterized by a high-speed deficit and level of turbulence which affects the performance of the wind turbines. The powers supplied are reduced and the loads on the rotors are greater, which results in the reduction of their life.

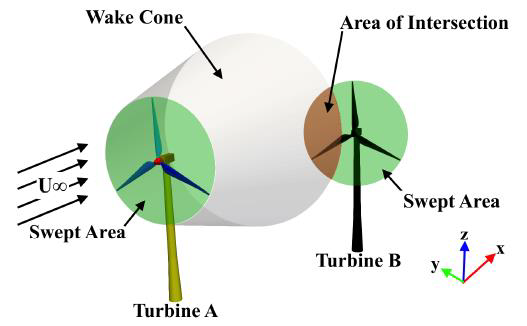

The Jensen wake model was used here for wind speed calculation. Figure 2 illustrates the influence of the downstream turbine by the propagation of the wake from the upstream turbine. The variation of the wake diameter depends on the size of the rotor and the wake minimization coefficient.

Figure 2. Influence of the downstream turbine by the propagation of the wake from the upstream turbine. Image Credit: Bellat, A et al.

Case Study: Horns Rev 1 Wind Farm

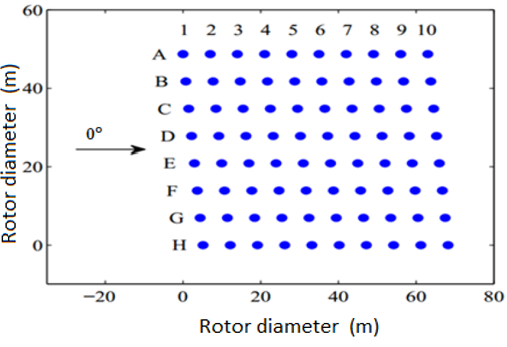

The Horns-rev1 wind farm located in the North Sea 14 km from the west coast of Denmark covers an area of approximately 20 km2. It is composed of 80 Vestas-type wind turbines placed in a regular arrangement of 8 rows and 10 columns with the inter-distance between the wind turbines equal to 7 times the diameter of the rotor for a wind direction equal to 0° as shown in Figure 3.

Figure 3. Presentation of the Horns-rev 1 marine wind farm. Image Credit: Bellat, A et al.

Objective Function

The aim of the studied objective function is to maximize the power and minimize the cost of a wind farm. To achieve the expectations of the objective function, the wind farm studied was updated by installing new wind turbines outside or inside a wind farm while respecting the constraints related to the wind farm area and the cost of installation.

Optimization Algorithm

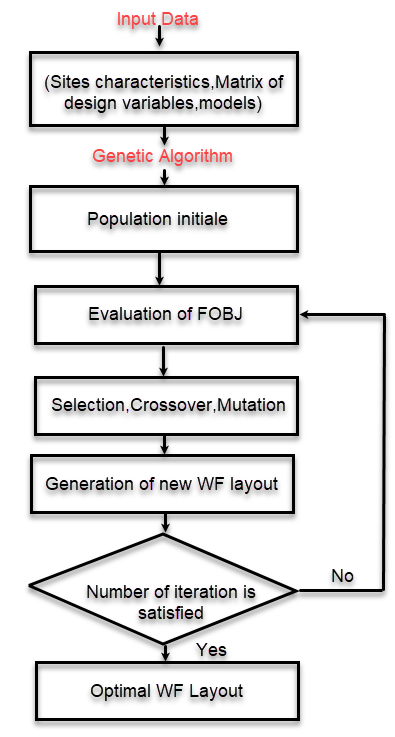

Many studies have shown that genetic algorithms (GA) are very effective in solving optimization problems. Hence, GA has been used here to optimize wind farms even if they are expensive.

Figure 4 illustrates a flowchart of the genetic algorithm, showing the optimization procedure as per the objective function defined above.

Figure 4. Genetic algorithm steps. Image Credit: Bellat, A et al.

The selection of turbines is limited to the same models of turbines existing in the studied wind farm (Vestas). Table 1 gives the code, the diameter of the rotor, the nominal speed, and the nominal power.

Table 1. Turbine data used in the optimization. Credit: Bellat, A et al.

| Turbine Code |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

| Rated Power (Kw) |

1815 |

1815 |

2000 |

2000 |

2000 |

2000 |

2600 |

| Rotor Diameter (m) |

90 |

100 |

80 |

90 |

100 |

10 |

100 |

| Rated Speed (m/s) |

13 |

11.5 |

14 |

13 |

12 |

11 |

15 |

| Turbine Code |

8 |

9 |

10 |

11 |

12 |

13 |

14 |

| Rated Power (Kw) |

3000 |

3000 |

3000 |

3075 |

3300 |

3300 |

3300 |

| Rotor Diameter (m) |

90 |

112 |

126 |

112 |

105 |

112 |

117 |

| Rated Speed (m/s) |

16 |

12 |

10.5 |

13 |

13.5 |

12.5 |

13 |

| Turbine Code |

15 |

16 |

17 |

18 |

19 |

|

|

| Rated Power (Kw) |

3450 |

3450 |

3450 |

3450 |

3450 |

|

|

| Rotor Diameter (m) |

105 |

112 |

117 |

126 |

136 |

|

|

| Rated Speed (m/s) |

13.5 |

12.5 |

11.5 |

11.5 |

11 |

|

|

Results

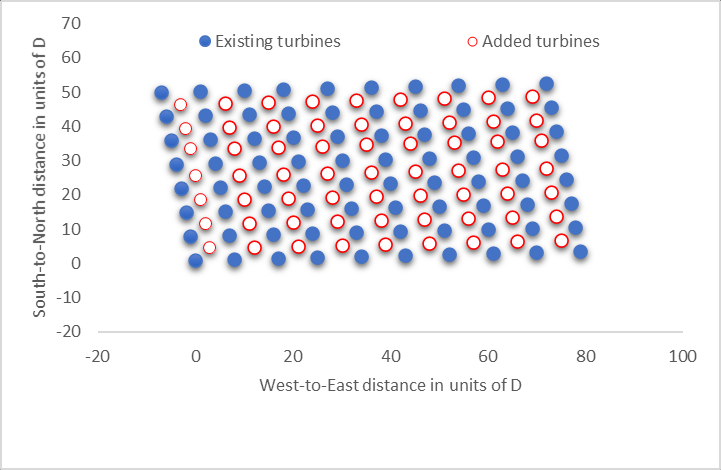

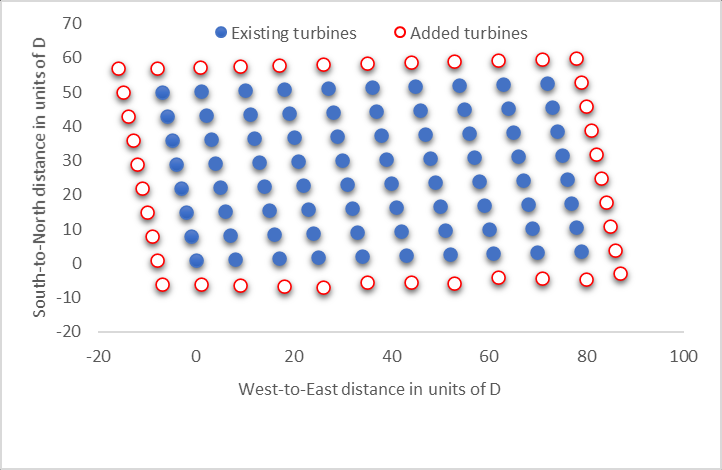

To evaluate the approach, two wind farm upgrade proposals were tested. Figure 5 and Figure 6 respectively show these two proposals. The existing turbines are numbered from 1 to 80 while the others are numbered from 81.

Figure 5. Internal upgrade proposal. Image Credit: Bellat, A et al.

To respect a minimum distance of 3.5 D (where D is the turbine diameter) between the turbines, the number of turbines added internally is 63 while externally equal to 40 and they all take on the red color.

Figure 6. External upgrade proposal. Image Credit: Bellat, A et al.

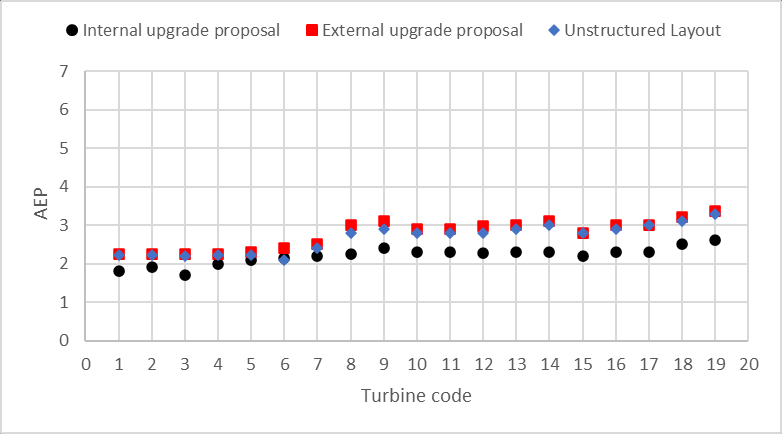

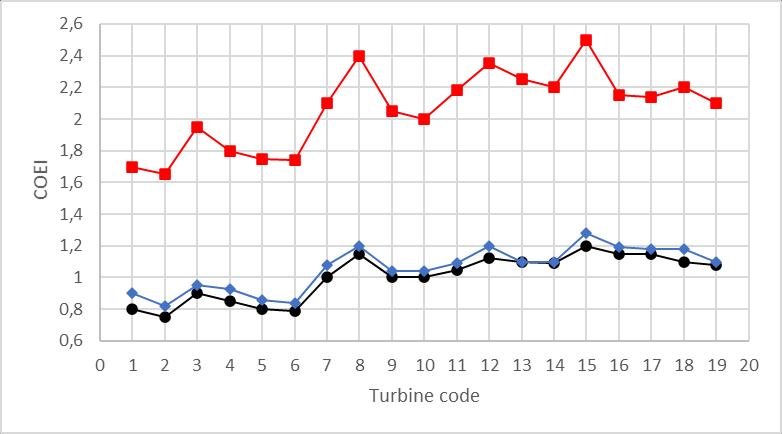

Figure 7 shows the annual energy production (AEP) of each wind turbine.

Figure 7. Annual energy production for each turbine by the studied objective function. Image Credit: Bellat, A et al.

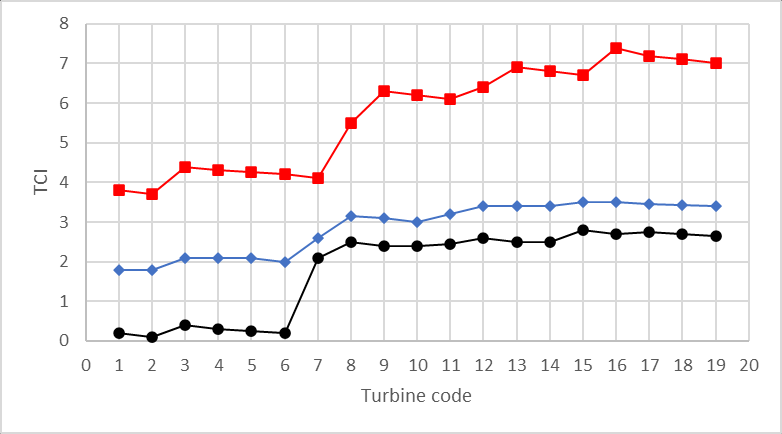

The results of Figure 7 and Figure 8 show a compromise between the annual production of energy and the cost; however, in the internal proposal of turbines, the AEP varies between 1.95 and 2.70. Moreover, the cost varies according to the type of turbine between 1.40 to 2.85.

Figure 8. Normalized total cost index. Image Credit: Bellat, A et al.

By contrast, the external openings with only one type of turbine have an AEP value varying between 2.21 to 3.31, and with regard to the TCI, the values vary between 3.85 and 7.4. Small wind turbines are ideal for internal upgrades with a relatively reasonable cost and higher AEP.

On the other hand, large wind turbines increase the cost of energy production. The increase of the AEP in the case of the external update is accompanied by an increase in the cost. This is explained by the added area which presents an important rate in the calculation of the cost.

Figure 9 shows that the internal updates are close to unity. This is explained by an increase in AEP in accordance with the TCI.

Figure 9. Normalized cost of energy index. Image Credit: Bellat, A et al.

Conclusions

This article studies the leveling of wind farms and evaluated the objective function which aims to maximize energy and minimize the cost. Two approaches were adopted: the addition of the turbines internally and externally. The results showed that both approaches are interesting in terms of annual energy production. However, the cost is relatively high in updating externally than internally.

Journal Reference:

Bellat, A., Mansouri, K., Raihani, A., (2021) Optimizing the layout of wind turbines by upgrading a wind farm. E3S Web of Conferences, 297, p. 01038. Available at: https://doaj.org/article/67bf2713d2dc4e73b5c9f9be5d3a22c1.

References and Further Reading

- IRENA. Renewable Power Generation Costs in 2017; International Renewable Energy Agency: Abu Dhabi, UAE, 2018. Available at: https://www.irena.org/publications/2018/jan/renewable-power-generation-costs-in-2017

- Global Wind Statistics 2017. Global Wind Energy Council (GWEC), February 2018. Available at: https://gwec.net/wp-content/uploads/vip/GWEC_PRstats2017_EN-003_FINAL.pdf

- World Energy Perspectives 2016. EXECUTIVE SUMMARY. World Energy Council. Available at: https://www.worldenergy.org/assets/downloads/20160906_Resilience_Cyber_Executive_Summary_WEB.pdf

- The shift Project Data Portal. Available at: theshiftproject.org/en/data-portal/

- BP Statistical Review of World Energy. June 2017. Available at: https://www.connaissancedesenergies.org/sites/default/files/pdf-actualites/bp-statistical-review-of-world-energy-2017-full-report.pdf

- Environmental Impacts of Wind Power. Available at: https://www.ucsusa.org/resources/environmental-impacts-wind-power

- Mosetti, G., et al. (1994) Optimization of wind turbine positioning in large wind farms by means of a genetic algorithm. Journal of Wind Engineering & Industrial Aerodynamics, 51, pp. 105–116. doi.org/10.1016/0167-6105(94)90080-9.

- 2014 Wind Technologies Market Report; US Department of Energy, Wind and Water Power Technologies Office: Berkeley, CA, USA, 2015.

- Lindvig, K (2010) The installation and servicing of offshore wind farms. In European Forum for Renewable Energy Sources; A2SEA A/S: Fredericia, Denmark.

- Saraswati, N., et al. (2017). Operation and Maintenance Map of U.S. Offshore Wind Farms; ECN-E–17-028. The Netherlands, November 2017. Available at: https://publicaties.ecn.nl/PdfFetch.aspx?nr=ECN-E--17-028

- Wind Farm Lifecycle.

- Hou, P., et al. (2017). Offshore wind farm repowering optimization. Applied Energy, 208, pp. 834–844. doi.org/10.1016/j.apenergy.2017.09.064.

- Topham, E., et al. (2017) Sustainable decommissioning of an offshore wind farm. Renewable Energy, 102, pp. 470–480. doi.org/10.1016/j.renene.2016.10.066.

- Sommer, A & Hansen, K (2002). Wind Resources at Horns Rev; Technical Report, Report No. D-160949; TechWise A/S: Fredericia, Denmark, December; p. 69.

- Jensen, L., et al. (2004) Wake Measurements from the Horns Rev Wind Farm; EWEC: London, UK; pp. 22–25.

- Overview of the Energy Sector. Available at: https://ens.dk/en/our-services/statistics-data-key-figures-and-energy-maps/overview-energy-sector

- Barthelmie, R., et al. (2009) Modelling and measuring flow and wind turbine wakes in large wind farms offshore. Wind Energy, 12, pp. 431–444. doi.org/10.1002/we.348.

- Rathmann, O., et al. (2006) Wind turbine wake model for wind farm power production. In Proceedings of the European Wind Energy Conference, Athens, Greece, 27 February–2 March.

- Barthelmie, R., et al. (2010) Quantifying the impact of wind turbine wakes on power output at offshore wind farms. Journal of Atmospheric and Oceanic Technology, 27, pp. 1302–1317. doi.org/10.1175/2010JTECHA1398.1.

- Frandsen, S., et al. (2006) Analytical modelling of wind speed deficit in large offshore wind farms. Wind Energy, 9, pp. 39–53. doi.org/10.1002/we.189.

- Frandsen, S., et al. (2009) The making of a second-generation wind farm efficiency model complex. Wind Energy, 12, pp. 445–458. doi.org/10.1002/we.351.

- Beaucage, P., et al. (2012) Overview of six commercial and research wake models for large offshore wind farms. In Proceedings of the European Wind Energy Conference & Exhibition; European Wind Energy Association (EWEA 2012), Copenhagen, Denmark, 16–19 April.

- Rivas, R., et al. (2009) Solving the turbine positioning problem for large offshore windfarms by simulated annealing. Wind Energy, 33, pp. 287–297. doi.org/10.1260/0309-524X.33.3.287.

- Vezyris, C (2012) Offshore Wind Farm Optimization Investigation of Unconventional and Random Layouts. Master’s Thesis, TU Delft, Delft, The Netherlands.

- Park, J & Law, K (2015) Layout optimization for maximizing wind farm power production using sequential convex programming. Applied Energy, 151, pp. 320–334. doi.org/10.1016/j.apenergy.2015.03.139.

- Abdulrahman, M & Wood, D (2017) Investigating the power-COE trade-off for wind farm layout optimization considering commercial turbine selection and hub height variation. Renewable Energy, 102, pp. 267–516. doi.org/10.1016/j.renene.2016.10.038.

- Feng, J & Shen, W Z (2015) Modelling wind for wind farm layout optimization using joint distribution of wind speed and wind direction. Energies, 8, pp. 3075–3092. doi.org/10.3390/en8043075.

- Herbert-Acero, J.-F., et al. (2009) Linear wind farm layout optimization through computational intelligence. In Proceedings of the 8th Mexican International Conference on Artificial Intelligence, Guanajuato, Mexico, 9–13 November; pp. 692–703.

- Tesauro, A., et al. (2012). State of the art of wind farm optimization. In Proceedings of the European Wind Energy Conference & Exhibition; European Wind Energy Association (EWEA 2012), Copenhagen, Denmark, 16–19 April.

- Chowdhury, S., et al. (2013) Optimizing the arrangement and the selection of turbines for wind farms subject to varying wind conditions. Renewable Energy, 52, pp. 273–282. doi.org/10.1016/j.renene.2012.10.017.

- Chen, Y., et al. (2013) Wind farm layout optimization using genetic algorithm with different hub height wind turbines. Energy Conversion and Management, 70, pp. 56–65. doi.org/10.1016/j.enconman.2013.02.007.