AZoCleantech speaks to Dr. Junqiao Wu about his team's smart-roof coating development. The technology could be used to transform roof materials, automatically disabling radioactive cooling in the winter and keeping us warm and cool depending on the season.

How did you begin your research into roof coatings?

I have been studying material physics of the phase change material, vanadium dioxide, for many years [e.g., Science, 355, 371 (2017) and Nature Nanotech. 4, 732 (2009)]. When I read the literature on radiative cooling, I started wondering, what if we are in the winter when there is a need for heat retention as opposed to radiating cooling? I then realized that vanadium dioxide can be used to make a temperature-adaptive, switchable roof material.

What current cool-roof systems are available?

Currently, roof materials can be made with constant high emissivity in the thermal infrared (8~14 micron), simultaneously with minimal solar absorption. These materials are good for strong passive radiative cooling to suit hot climates. Thermal emissivity is a physical parameter to characterize how strongly a surface can radiate heat away from the surface to the sky. A material with high thermal emissivity stays cooler than low emissive materials, even if they both sit in the same environment.

Your team has developed a smart-roof coating. What does the coating consist of?

The coating is a three-layer structure, made of periodic island arrays of the phase change material tungsten-doped vanadium dioxide, sitting on top of a transparent barium fluoride layer, with a metal layer underneath. The entire structure is supported by flexible tape.

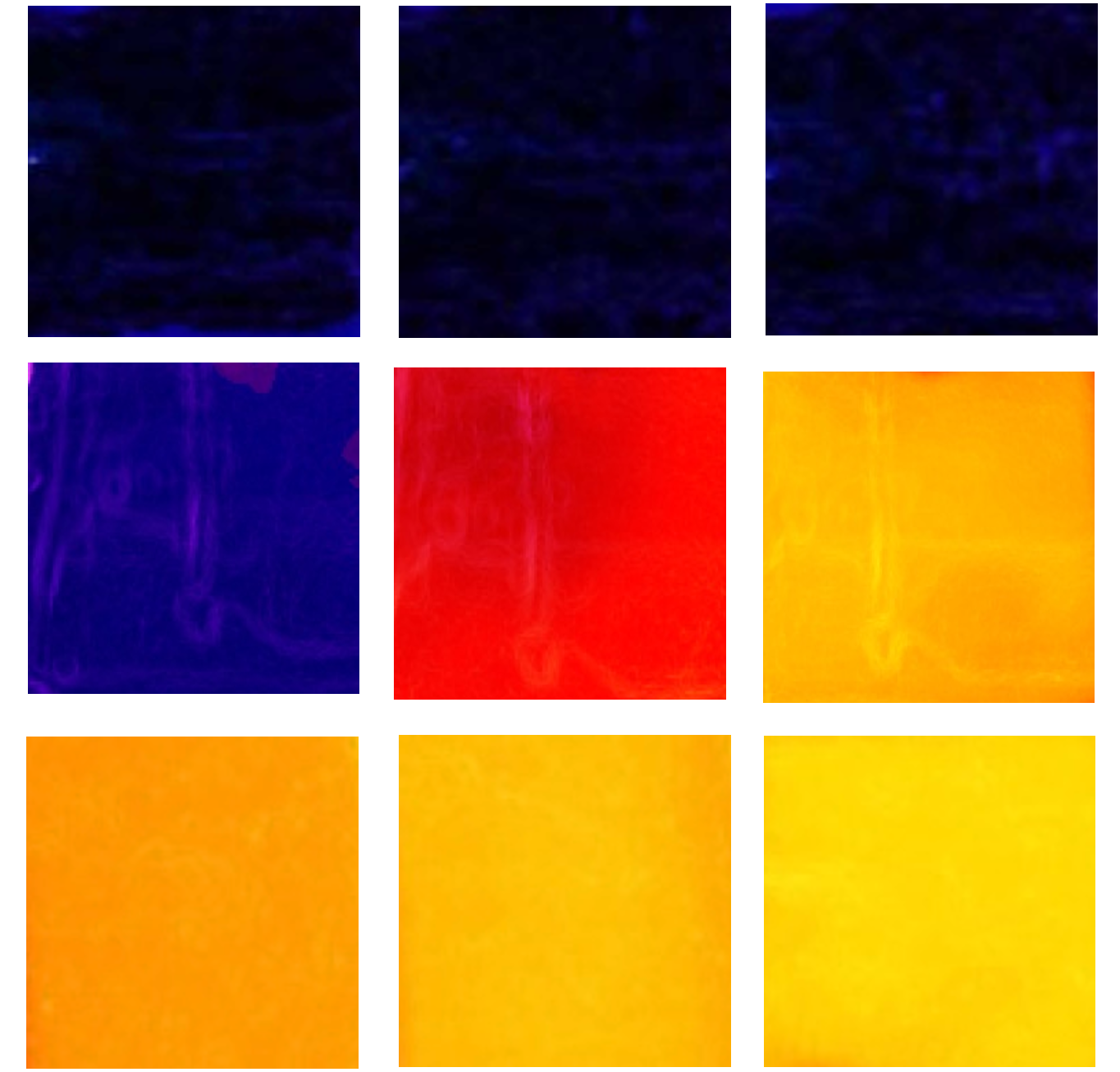

Thermal images of: (top row) a regular roof material with low emissivity, (middle row) TARC, and (bottom row) a regular roof material with high emissivity, imaged with a thermal camera at: (left column) 20 degrees Celcius, (middle column) 25 degrees Celsius, and (right column) 30 degrees Celcius. Brighter images indicate radiation of more heat from the surface (hence stronger radiative cooling). It is clear that TARC is unique in the sense that it switches from a low-radiation mode at low temperatures to a high-radiation mode at high temperatures. Image Credit: Junqiao Wu, UC Berkeley

How does the smart-roof coating differ from current technology on the market?

Hot climates need roofs that have low solar absorption and high thermal emissivity to keep the house cool, while cold weather requires roofs that have high solar absorption and low thermal emissivity to keep the house warm. However, for most climates, the weather is hot in the summer or daytime, and cold in winter or nighttime, hence the need for a roof that can automatically (namely, without a user’s activation or energy input) switch between these two modes. Our technology precisely addresses this need.

What are the main advantages of the coating?

The coating automatically switches the emissivity in response to environmental temperature and without human activation. As a result, it can keep the house relatively warm when the temperature is below 22 oC and keep the house relatively cool when the temperature is above 26 oC, without consuming gas or electricity. The structure is designed so that it does not maximize the building energy saving in the summer, nor in the winter, but saves the maximal amount of energy over the entire year for a given climate. We call it a “holistic approach”.

How does the material help keep our homes warm and cool depending on the weather outside? How does this help reduce energy costs?

In hot weather, a roof with high thermal emissivity can radiate heat away into the sky to keep the house relatively cool, saving air conditioning energy; in cold weather, a roof with low emissivity can maximally retain the heat inside the house and keep it warm, saving energy needed for heating. Our roof takes advantage of a temperature-triggered solid-solid phase transition in the structure, to switch between a high emissivity state at a temperature above 26 oC and a low emissivity state at a temperature below 22 oC, hence maximally saving energy, not in the summer nor in the winter, but holistically over all seasons around the year.

Image Credit: Alexphot/Shutterstock.com

Is there a potential for this to be adopted on a wider scale? What are the challenges that may be faced and how could these be overcome?

We are working on developing the product at larger scales and at a lower cost. We must use different materials with unique material processing techniques. We are making progress already.

How important is emissions-free air conditioning and heating in a warming world?

It can be estimated that for most climate zones, using our product on the roof can save residential building energy for heating and air conditioning by about 10% over the year, when compared to other existing roof materials.

How does this material automatically turn off the radioactive cooling in the winter?

The physical mechanism is based on a solid-solid phase transition in the key material (vanadium dioxide), where the material automatically changes from being an insulator and transparent to thermal infrared at low temperatures, to being a metal and reflective to thermal infrared at high temperatures. The phase transition is driven by environmental temperature, not by human activation: in a similar way to water automatically changing from solid ice to liquid water at a certain temperature, except that here the change of the material is from a solid-state to another solid-state. Across the phase change at the pre-set temperature, the emissivity and intensity of radiation from the material are drastically changed.

When carrying out your study, how were you able to predict the annual energy savings the temperature-adaptive radiative coating (TARC) provides in different climate zones?

Weather information is available for all climate zones in the weather database. Using a physical model, we simulate the surface temperature of TARC compared to all other non-switching roof materials for different cities at different hours over 365 days of the year. The simulation considers sunlight absorption, thermal radiation, as well as air convection, all injecting into or dissipating energy from the roof. The surface temperature difference of the roofs is then converted to energy savings needed to keep the internal temperature of the house to a preset, comfortable temperature.

What challenges have you faced when developing TARC?

The project spanned over a period of three years. Synthesizing the material, designing the structure, fabricating the device, characterizing the product, and simulating the performance, all took us significant amounts of trials and corrections. We finally succeeded.

How could the coating be used as thermal protection in batteries? How could this benefit several different industries?

Like human beings, rechargeable batteries also like to live in a comfortable range of temperatures. Both overheating and overcooling would damage the batteries and shorten its lifetime. It is envisioned that TARC can also be used for battery thermal management at zero energy consumption. As is known, rechargeable batteries are used broadly in many industries such as electronics, space, and transportation.

What are the next steps for the project?

Scaling up the product, elongating its lifetime, optimizing its performance, and customizing for different application scenarios.

Where can readers find more information?

The paper is published at Science, 374, 1504 (2021). It is available at: https://www.science.org/doi/10.1126/science.abf7136

About Dr. Junqiao Wu

Dr. Junqiao Wu is currently a Materials Science Professor at the University of California, Berkeley, and a faculty scientist at the Lawrence Berkeley National Laboratory. His honors include the 29th Ross N. Tucker Memorial Award, the Presidential Early Career Award for Scientists and Engineers (PECASE) from the White House, and elected Fellow from the American Physical Society (APS).

Dr. Junqiao Wu is currently a Materials Science Professor at the University of California, Berkeley, and a faculty scientist at the Lawrence Berkeley National Laboratory. His honors include the 29th Ross N. Tucker Memorial Award, the Presidential Early Career Award for Scientists and Engineers (PECASE) from the White House, and elected Fellow from the American Physical Society (APS).

The Wu group explores physics and applications of electronic materials, and has published over 250 highly cited papers in the field. For more information, see the Wu group research website at http://wu.mse.berkeley.edu

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.