Lithium-ion batteries have been instrumental in powering the modern-day world. However, numerous issues have been raised about whether batteries should continue to play a significant role as the world progresses toward a greener future.

Image Credit: asharkyu/Shutterstock.com

What are Lithium-Ion Batteries?

Lithium-ion (Li-ion) batteries are widely used to power up modern-day consumer electronics.

The anode of the battery is typically constructed of graphite (carbon), and the cathode is usually made up of lithium iron phosphate (LiFePO4) or lithium cobalt oxide (LiCoO2) separated by electrolyte-filled porous separators. Cathodes and anodes are linked to current collector terminals, and the electrode package is enclosed in a case.

The main advantages of lithium-ion batteries over other batteries are high energy capacity, a large number of charge-discharge cycles, and low self-discharge. It is used as an energy storage device in power systems and power source in electric vehicles.

How Do Lithium-Ion Batteries Work?

Lithium batteries provide optimal conditions for the movement of metal ions within the electrodes. When the battery is charged, a voltage of a certain magnitude is applied to the electrodes, stimulating lithium ions to move from the lithium cathode to the carbon anode. An oxidative reaction accompanies this process.

During discharge, a load is applied to the system, causing the metal ions to move in the opposite direction.

Applications of Lithium-Ion Batteries

For many years, the primary market for lithium-ion batteries has been mobile phones. However, this situation is changing as lithium-ion batteries are increasingly used in health care devices, electric vehicles, and unmanned aerial vehicles (UAVs).

Healthcare devices

Lithium-ion batteries are prime candidates for health care devices due to their small size, weight, high energy density, and long lifespan. Pacemakers, implantable radio transmitters, wearable biosensors, gastric stimulators, defibrillators, surgical tools, and monitors are medical devices that use Li-ion batteries.

Electric vehicles

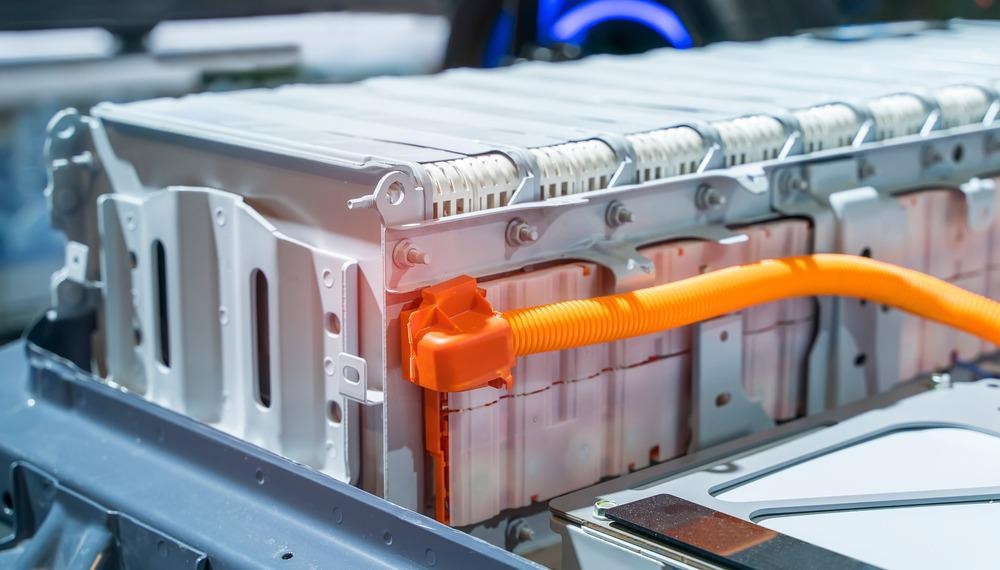

Image Credit: Immersion Imagery/Shutterstock.com

Li-ion batteries are also used in electric vehicles. This industry has had a significant increase in recent years thanks to the different policies implemented by governments to reduce gas emissions.

It is predicted that the Li-ion battery market for electric vehicles will reach almost $70 billion by 2026.

Are Lithium-Ion Batteries Bad For The Environment?

Lithium mining in Andean countries is carried out using saline water. Even though it is not suitable for drinking, the absence of saline water can significantly impact water and environmental resources.

One ton of lithium requires a staggering 2.2 million gallons of water. More than half of the water in Chile's Salar de Atacama has been used by mining activities in the region, significantly impacting local farmers.

Lithium batteries contain potentially toxic nickel, copper, and lead materials. When disposed of improperly, used batteries can lead to an environmental disaster, and if stored uncontrolled, they become explosive.

The Environmental and Ethical Problems With Lithium-Ion Batteries

Video Credit: Bloomberg Technology/YouTube.com

Lithium-Ion Waste

Lithium-ion batteries waste is a valuable resource. The materials and metals used in Li-ion batteries are not found abundantly, and access to these resources is critical for everyone today.

Initial concerns about the lack of natural resources to expand lithium-ion battery production were related to lithium. Today, however, cobalt reserves are of more significant concern.

Some countries are now arguing that end-of-life batteries with a high cobalt content should be immediately recycled to ensure the supply of this metal.

Lithium-Ion Battery Recycling

Most of the materials that make up batteries are recyclable. This also shows how important it is to collect them for recycling. Specialized companies collect used batteries for their recycling.

First, the body is opened and disassembled into its components. Then the electrolyte, containing lithium salts, is drained. After that, the anode and cathode plates are separated and cleaned.

The next stage is the processing of copper and aluminum parts for recycling. Battery cases are shredded to be further used to produce new products.

Lithium-Ion Battery Leakage

Electrolyte leakage is a common indication of lithium battery (LIB) failure, and a minor quantity of leakage of electrolyte vapor might be considered an early indication of probable battery damage. The explosion of gases generated by electrolyte leakage causes a substantial share of LIB safety issues, whereas minor damage to battery packs is often impossible to detect.

LIB electrolytes are mostly made up of difficult-to-detect volatile and redox neutral solvents such as methyl ethyl carbonate (EMC), vinyl carbonate, or dimethyl carbonate (DMC).

Recent Developments in Lithium-Ion Battery Alternatives

Researchers at the University of Texas have invented a stable sodium-based battery, which recharges as fast as a standard Li-ion battery.

The researchers created sodium antimony intermetallic telluride, a new anode material that minimizes the risk of dendritic growth and surface corrosion. It improves battery stability and allows fast charging, similar to a lithium-ion battery.

In collaboration with the National Institute of Energy in Slovenia, researchers from the Chalmers University of Technology in Sweden are creating an aluminum-ion battery. Due to the quantity of aluminum in the Earth's crust and its theoretical potential to carry charges better than lithium, this battery type presents a possible alternative to lithium-ion.

Batteries manufactured from aluminum rather than lithium may provide more economical, large-scale storage for renewable projects because of the reduction in material and environmental costs.

Companies Making Batteries More Green and Efficient

IBM has invented a battery free of nickel, cobalt, and other metals, avoiding the humanitarian and environmental concerns of lithium-ion batteries. The battery is built using materials taken from saltwater, which is a considerably less invasive means of sourcing than mining.

They also demonstrated that the battery beats Li-ion alternatives, indicating that it can improve energy storage and electric vehicles. Furthermore, reaching an 80 percent charge takes only five minutes.

The safer, non-flammable battery will be cost-effective due to the unique materials-sourcing technique.

AquaBattery, a Dutch startup, has invented a battery that only employs saltwater as a storage medium. Simply adding water reservoirs or using larger tanks increases the storage capacity.

Unlike conventional lithium-ion batteries, the team's technique uses non-toxic and abundant elements such as water and table salt. This provides fire and health protection while also reducing carbon emissions.

AquaBattery claims that its solution will be highly scalable, low-cost and long-lasting.

Future Outlooks of Batteries

Batteries are essential for a low-carbon future on Earth, and it is in everyone's best interests to ensure that these batteries are safe, clean and long-lasting.

Eco-friendly alternatives to lithium-ion batteries must be considered and developed, and looking at how Li-ion battery materials can be reused, recycled, and repurposed is essential to a greener future.

References and Further Readings

Aouf, R. (2020). IBM Proposes Sustainable Successor To Lithium-Ion Battery. [Online] Dezeen. Available at: https://www.dezeen.com/2020/01/06/ibm-research-sustainable-battery-sea-water/ (Accessed on 20 April 2022).

Bitenc, J., Lindahl, N., Vizintin, A., Abdelhamid, M. E., Dominko, R., & Johansson, P. (2020). Concept and electrochemical mechanism of an Al metal anode‒organic cathode battery. Energy Storage Materials, 24, 379-383. https://doi.org/10.1016/j.ensm.2019.07.033

Gaines, L. L., & Dunn, J. B. (2014). Lithium-ion battery environmental impacts. In Lithium-Ion Batteries (pp. 483-508). Elsevier. https://doi.org/10.1016/B978-0-444-59513-3.00021-2

Harper, G., Sommerville, R., Kendrick, E., Driscoll, L., Slater, P., Stolkin, R., ... & Anderson, P. (2019). Recycling lithium-ion batteries from electric vehicles. Nature, 575(7781), 75-86. https://doi.org/10.1038/s41586-019-1682-5

Lu, Y., Zhang, S., Dai, S., Liu, D., Wang, X., Tang, W., ... & Huang, J. (2020). Ultrasensitive detection of electrolyte leakage from lithium-ion batteries by ionically conductive metal-organic frameworks. Matter, 3(3), 904-919. https://doi.org/10.1016/j.matt.2020.05.021

Wang, Y., Dong, H., Katyal, N., Hao, H., Liu, P., Celio, H., ... & Mitlin, D. (2022). A Sodium–Antimony–Telluride Intermetallic Allows Sodium‐Metal Cycling at 100% Depth of Discharge and as an Anode‐Free Metal Battery. Advanced Materials, 34(1), 2106005. https://doi.org/10.1002/adma.202106005

Wilson, J. (2022). Imperial Graduate Awarded €2.5 Million European Funding For Saltwater Battery. [Online] Imperial College London. Available at: https://www.imperial.ac.uk/news/234235/imperial-graduate-awarded-25-million-european/ (Accessed on 20 April 2022).

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.