The circular economy offers a solution to the linear system of “take, make, use, dispose.” It tries to maintain resources in use for as long as feasible, optimize their value while they are in use, and recover and regenerate products when they are no longer useful. Plastic sand bricks and blocks are a fantastic example of the type of innovation needed to develop a circular economy. This article aims to summarize research recently published in Sustainability.

Image Credit: Smit/Shutterstock.com

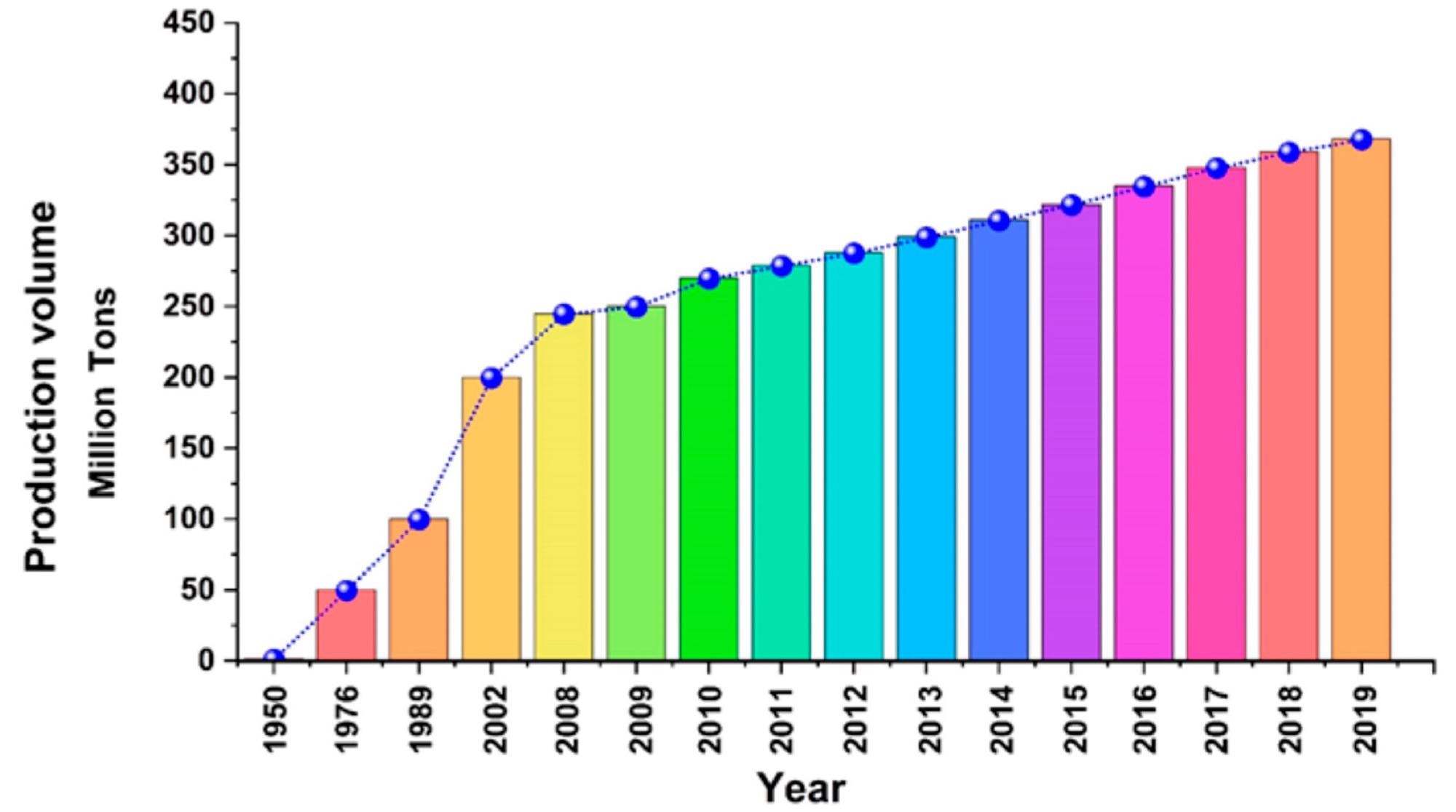

Figure 1 depicts the growth of plastic garbage from 1950 to 2019. Due to present consumption patterns and waste management techniques, landfills and the natural environment will contain around 12 billion tons of plastic litter by 2050.

As a result, different initiatives have been made throughout the world, especially in wealthy countries, to convert plastic trash into valuable items. Since the construction sector rules most economies and consumes the rawest resources, there is a lot of opportunity for developing new construction materials from plastic trash.

Figure 1. World plastic waste generation 1950 to 2019. Image Credit: Khadke, et al., 2021

This study discusses current advancements in the creation of plastic-sand mixtures. Plastic sand bricks are used in a variety of civil engineering applications, including precast bricks, partition walls, roof tiles, canal linings, and paving bricks.

These applications are important for assisting in the disposal of plastic trash that accumulates worldwide and remains non-degradable. Investigations on the use of plastic waste to enhance the qualities of concrete are not covered in this study since the topic has already been covered extensively, as shown in Table 1.

Table 1. A list of literature review studies discussing the use of plastic in construction materials. Source: Al-Sinan & Bubshait, 2022

| Title |

Review Scope |

| “Use of Recycled Plastics in Concrete: A Critical Review” [21] |

Use of plastic in concrete mix |

| “Potential Use of Plastic Waste as Construction Materials: Recent Progress and Future Prospect” [22] |

Use of plastic in construction material (general) |

| “Use of Recycled Plastic as Fine Aggregate in Cementitious Composites: A Review” [23] |

Use of plastic as fine aggregate |

| “Engineering Properties of Concrete with Waste Recycled Plastic: A Review” [24] |

Use of plastic in concrete |

| “Mortar and Concrete Composites with Recycled Plastic: A Review” [25] |

Use of plastic in cement and concrete |

| “Use of Plastic Waste as Aggregate in Cement Mortar and Concrete Preparation: A Review” [26] |

Use of plastic in cement and concrete |

| “Application of Plastic Wastes in Construction Materials: A Review Using the Concept of Life-Cycle Assessment in the Context of Recent Research for Future Perspectives” [27] |

Use of plastic in construction material (general) |

Methodology

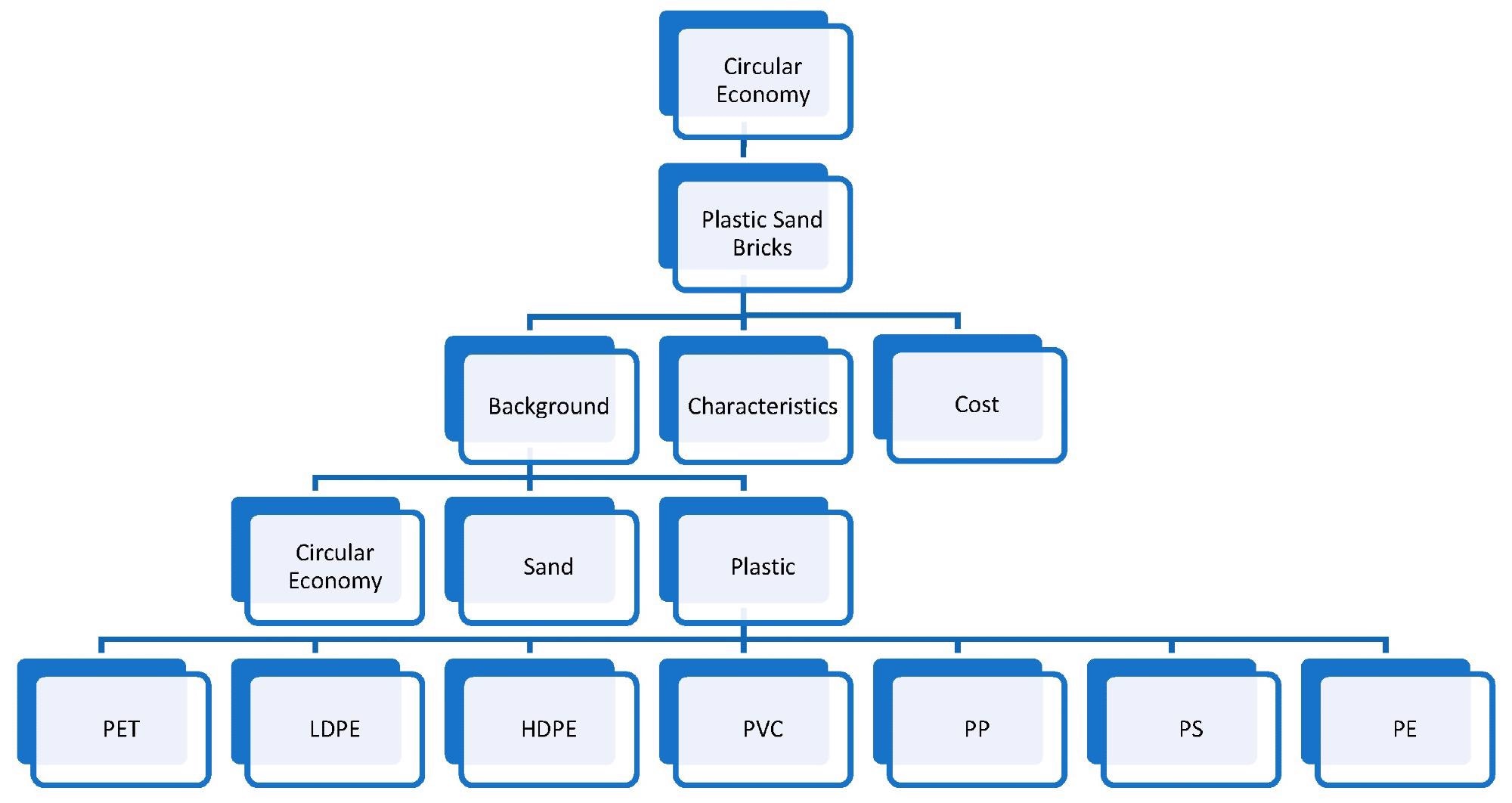

The cyclical economy and the practicality of employing plastic sand bricks as an alternative construction material are the focus of the mind map used in this review article (Figure 2).

Figure 2. The mind map is used in this literature review. Image Credit: Al-Sinan & Bubshait, 2022

The literature review was primarily undertaken with the use of keywords. Plastic sand, plastic sand bricks, plastic sand blocks, plastic waste in construction, PET sand bricks, low-density polyethylene (LDPE) sand, high-density polyethylene (HDPE) sand, polyester (PE) sand, and nylon sand were among them.

Thermoplastic and thermosetting plastics are the two forms of plastic. Unlike thermoplastics, which can be bent, remolded, and recycled, thermosetting plastics stay in a stable, solid state once hardened.

Table 2 shows the many types of plastic, their uses, and features, as well as their potential for usage as recycled building materials.

Table 2. Types of plastic. Source: Al-Sinan & Bubshait, 2022

| Plastic Type |

Characteristics and Use/Construction Application |

| Polyethylene terephthalate (PET or PETE) |

Strong, clear, hard, and absorbs very little water. Example of use: beverage bottles and food bottles.

Can be utilized in different types of construction materials, concrete, unfired clay brick, soil-cement block, asphalt-concrete mixture, mortar. |

| Low-density polyethylene (LDPE) |

Soft and flexible. Example of use: garbage bags.

Can potentially be used in the production of blocks and bricks. |

| High-density polyethylene (HDPE) |

White or colored, withstands high temperatures, has a high strength-to-density ratio. Examples of use: buckets and detergent bottles.

Can be used in the manufacturing of tables, plastic lumber, chairs, and other furniture. |

| Polyvinyl chloride (PVC) |

Rigid, hard, clear, extremely good tensile strength, and very dense. Examples of use: plumbing pipes and fittings.

Can be used as an aggregate/gravel in cement-based materials. |

| Polypropylene (PP) |

Hard, flexible, non-toxic, transparent, resistant to different chemicals, and withstands high temperatures. Examples of use: lunch boxes and potato chip bags.

Can be utilized as aggregates/gravel in asphalt mixtures. |

| Polystyrene (PS) |

Transparent, relatively hard, lightweight, and colorless. Examples of use: toys and disposable plastic cutlery and dinnerware.

Can be used as insulation materials (parts that are not highly stressed mechanically). |

| Polyester (PE) |

Stable, strong, lightweight, shock-absorbing, highly thermally efficient, energy absorbing, and resistant to most chemicals. Examples of use: safety belts and fabrics for conveyor belts. |

The use of plastic in construction products is compatible with long-term development and helps to improve environmental circumstances. Its use as a raw material in the production of bricks is discussed in the following section of the paper. Table 3 shows the papers that were picked based on the review selection method.

Table 3. List of the research title, type of materials, and scope of studies included in the review. Source: Al-Sinan & Bubshait, 2022

| Title |

Year |

Type of Material |

Scope of Study |

| “Plastic Wastes, Glass Bottles, and Paper: Eco-Building Materials for Making Sand Bricks” [33] |

2020 |

PET, LDPE, and HDPE |

plastic sand bricks |

| “Experimental Study on Strength Behaviour of Plastic Sand Bricks” [11] |

2021 |

PET, LDPE, and HDPE |

plastic sand bricks |

| “Study of Sand-Plastic Composite Using Optimal Mixture Design of Experiments for Best Compressive Strength” [40] |

2021 |

LDPE and HDPE |

plastic sand bricks |

| “Recycling Waste Plastic Bags as a Replacement for Cement in Production of Building Bricks and Concrete Blocks” [36] |

2020 |

melted plastic bags |

bricks and concrete blocks |

| |Utilization of Low-Density Polyethylene (LDPE) Plastic Wastes in the Production of Paving Tiles” [34] |

2020 |

molten plastics |

paving tiles |

| “The Effect of Composition of Plastic Waste Low Density Polyethylene (LDPE) with Sand to Pressure Strength and Density of Sand/LDPE Composite” [41] |

2019 |

LDPE |

plastic sand bricks |

| “Recycling High-Density Polyethylene (HDPE) into Construction Materials as a Key Step in Plastic Waste Reduction” [2] |

2018 |

HDPE |

pavers |

| “Comparative Study on Conventional HDPE Paver Blocks with M-Sand and Bagasse Ash as Constituent Materials” [42] |

2021 |

HDPE |

paver blocks |

| “An Experimental Study on Brick Manufactured Using M-Sand, Sawdust, and Recycled Plastic” [43] |

2019 |

PP |

plastic sand bricks |

| “Fabrication and Testing of Plastic Sand Bricks” [44] |

2019 |

PET |

plastic sand bricks |

| “Experimental Study on the Use of waste Polyethylene Terephthalate (PET) and River Sand in Roof Tile Production” [45] |

2019 |

PET |

roof tiles |

| “Manufacture of Tiles Using Waste Plastic and River Sand” [46] |

2019 |

PET |

roof tiles |

| “Effect of Waste PET on the Structural Properties of Burnt Bricks” [47] |

2020 |

PET |

burnt bricks |

| “Manufacturing of Bricks from HDPE and PP Plastic” [48] |

2020 |

HDPE and PP |

plastic sand bricks |

The following test was used to analyze the plastic bricks to traditional bricks: strength properties, water permeability, efflorescence, hardness, and soundness. Table 4 demonstrates the crushing values and water absorption for different plastic and sand mix combinations.

Table 4. Compressive strength and water absorption of various mixes. Source: Al-Sinan & Bubshait, 2022

| Plastic: Sand Ratio |

Maximum Load

(KN) |

Compressive Strength

N/mm2 |

Water Absorption |

| 1:2 |

232 |

9.17 Mpa |

0.346% |

| 1:3 |

162 |

6.4 Mpa |

1.57% |

| 1:4 |

88 |

3.5 Mpa |

1.467% |

The traditional bricks absorbed 7.08% of the water. The plastic bricks had no alkali, while the conventional bricks had alkali, according to the efflorescence test results. The brick’s hardness was determined through a hardness test. The soundness test resulted in a distinct ringing sound, suggesting that the product is of good quality. Furthermore, the plastic sand bricks were lighter than standard bricks.

Abdel Tawab et al. used melted plastic bags instead of cement to make bricks and concrete blocks. Melted waste plastic and sand were used to make the bricks, while melted waste plastic, sand, and gravel were used to make the blocks.

The bending moment, bending stress, and thermal conductivity of plastic sand brick with different percentages of LDPE are shown in Table 5.

Table 5. Physical characteristics of plastic sand bricks with various plastic percentages. Source: Al-Sinan & Bubshait, 2022

| Plastic:Sand |

Bending Moment

N·m |

Bending Stress

N·m−2 |

Thermal Conductivity

W/m·k |

| 2:1 |

1711.25 |

10.26 |

1.43 × 10−3 |

| 1:1 |

721.55 |

4.32 |

1.53 × 10−3 |

| 1:2 |

540 |

3.24 |

1.71 × 10−3 |

The thermal conductivity readings were identical in bricks and blocks with similar plastic content (50%). The bending moment, and thus the bending stress, improved with the plastic component in both bricks and blocks.

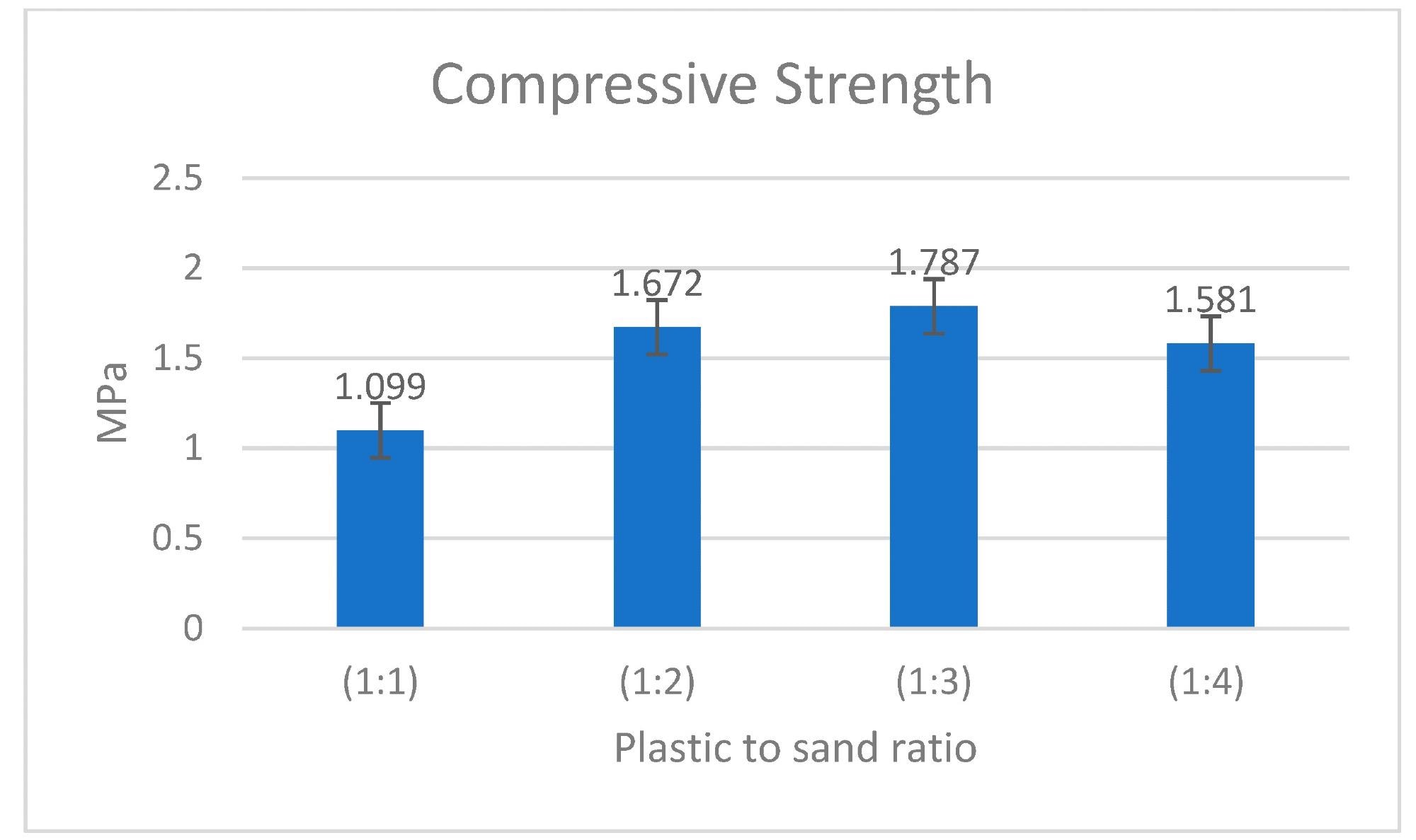

The compressive strength of different plastic to sand ratios is shown in Figure 3.

Figure 3. Compressive strength with various plastic to sand ratios. Image Credit: Osarumwense, et al., 2020

The highest load that a conventional sand-cement composite (control) could withstand was 29 KN. At a 1:3 ratio, the tile (sample) could withstand a maximum load of 39 KN.

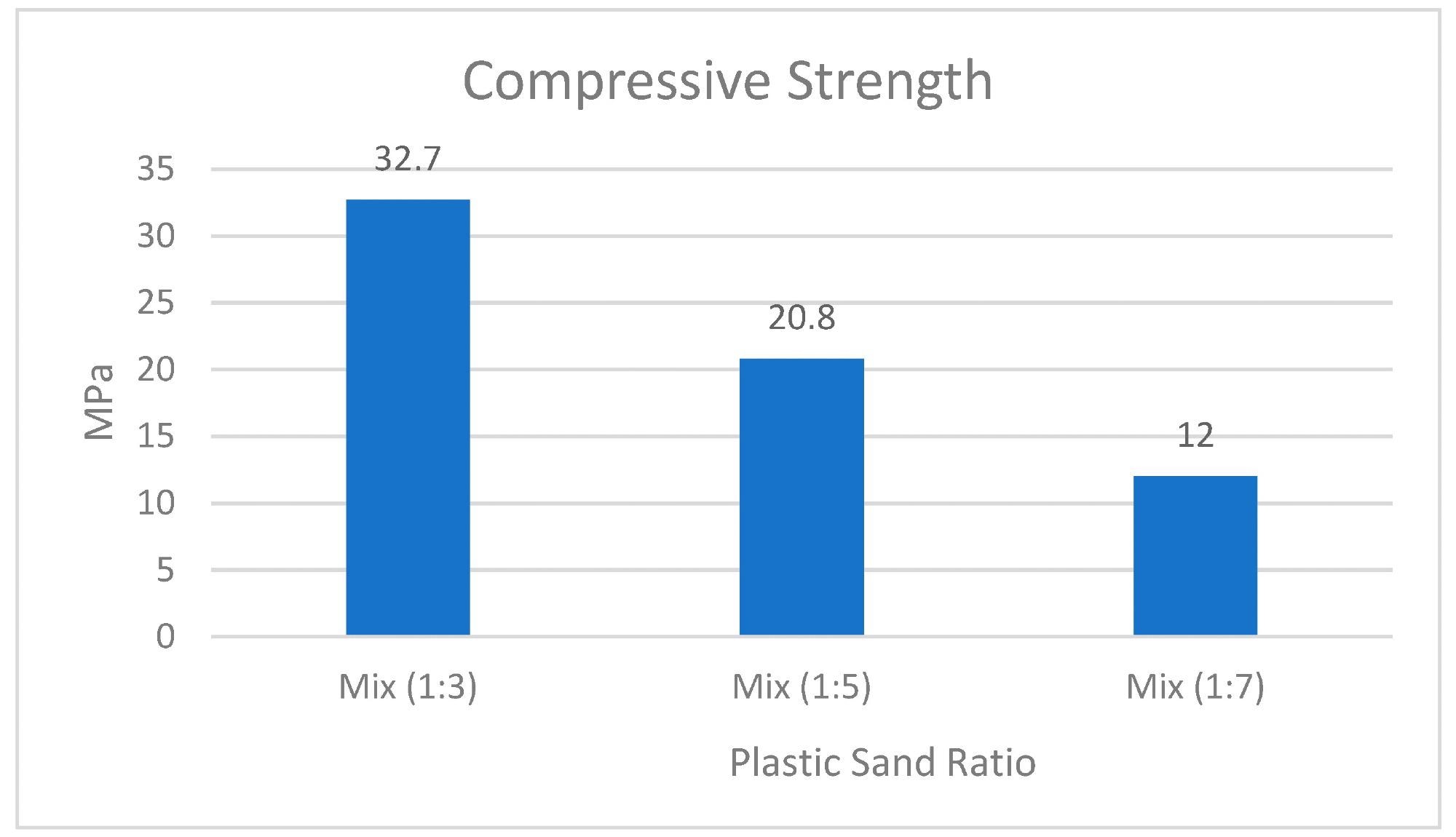

Susila et al. tested the strength properties of samples with LDPE plastic to sand ratios of 1:3, 1:5, and 1:7 at 200 °C. The samples with the highest average compressive strength of 32.7 Mpa had a 1:3 plastic to sand ratio and 3 mm sand grains (Figure 4).

Figure 4. Compressive strength average of the specimen with plastic and sand mixture. Image Credit: Susila, et al., 2019

Table 6 illustrates the compressive strength after compaction for the three sand to plastic ratios, as well as the strength properties after 12 hours of exposure to 35 °C.

Table 6. Compressive strength of various ratios after compaction and after 12 h of 35 °C exposure. Source: Dominique, et al., 2018

| Plastic:Sand Ratio |

Compressive Strength

MPa |

Compressive Strength

(after Heat Exposure)

MPa |

| 1:3 |

21.73 |

17.79 |

| 1:4 |

26.15 |

22.37 |

| 1:5 |

4.79 |

3.52 |

Chauhan et al., evaluate plastic waste (PET) and river sand bricks carried out the research. Table 7 shows the results of the compressive strength test.

Table 7. Compressive strength test results. Source: Chauhan, et al., 2018

| Plastic:Sand Ratio |

Maximum Load

(KN) |

Compressive Strength

(kg/cm2) |

| 1:2 |

500 |

193.87 (19.01 MPa) |

| 1:3 |

350 |

135.71 (13.31 MPa) |

| 1:4 |

165 |

63.97 (6.27 MPa) |

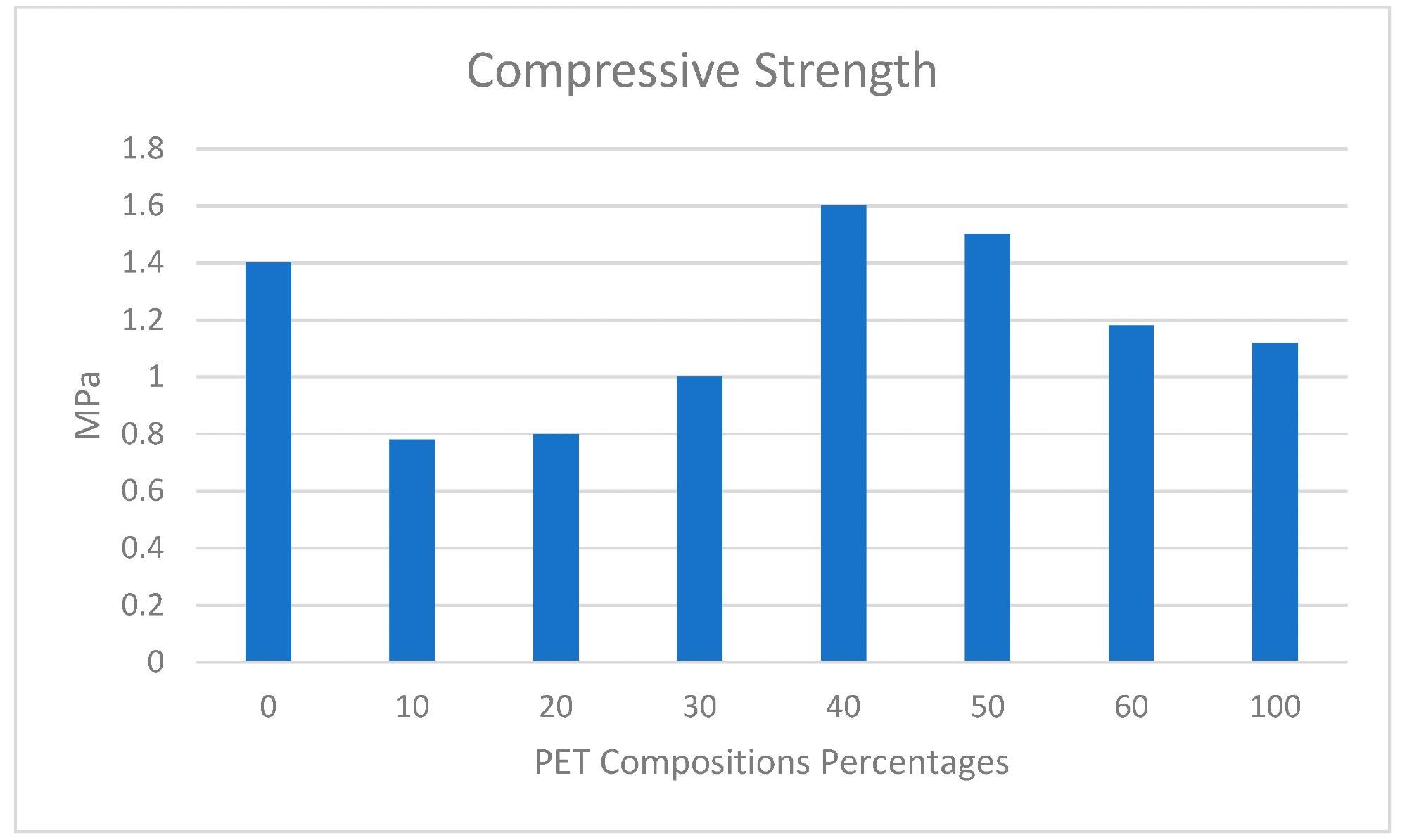

Bamigboye evaluated the performance of roof tiles made from recycled PET and river sand in various amounts. Eventually, it was discovered that composite tiles containing 40% PET had the maximum value, followed by those containing 50% PET (Figure 5).

Figure 5. Compressive strength average of the specimen with plastic and sand mixture. Image Credit: Bamigboye, et al. 2019

Mohan et al. investigated the feasibility of making bricks from HDPE and PP waste. To make the final brick, the mixture was heated to the plasticity zone, poured into a mold, and crushed. The compressive strengths of HDPE: PP bricks with various ratios, as well as the proportion of water absorption, are shown in Table 8.

Table 8. Compressive strength of various HDPE: PP ratios. Source: Mohan, et al., 2020

| HDPE:PP Ratio |

Compressive Load

(KN) |

Compressive Strength

MPa |

Water Absorption % |

| 50:50% |

157 |

7.5 |

0.44 |

| 40:60% |

97 |

4.64 |

0.25 |

| 70:30% |

128 |

6.12 |

0.23 |

Discussion

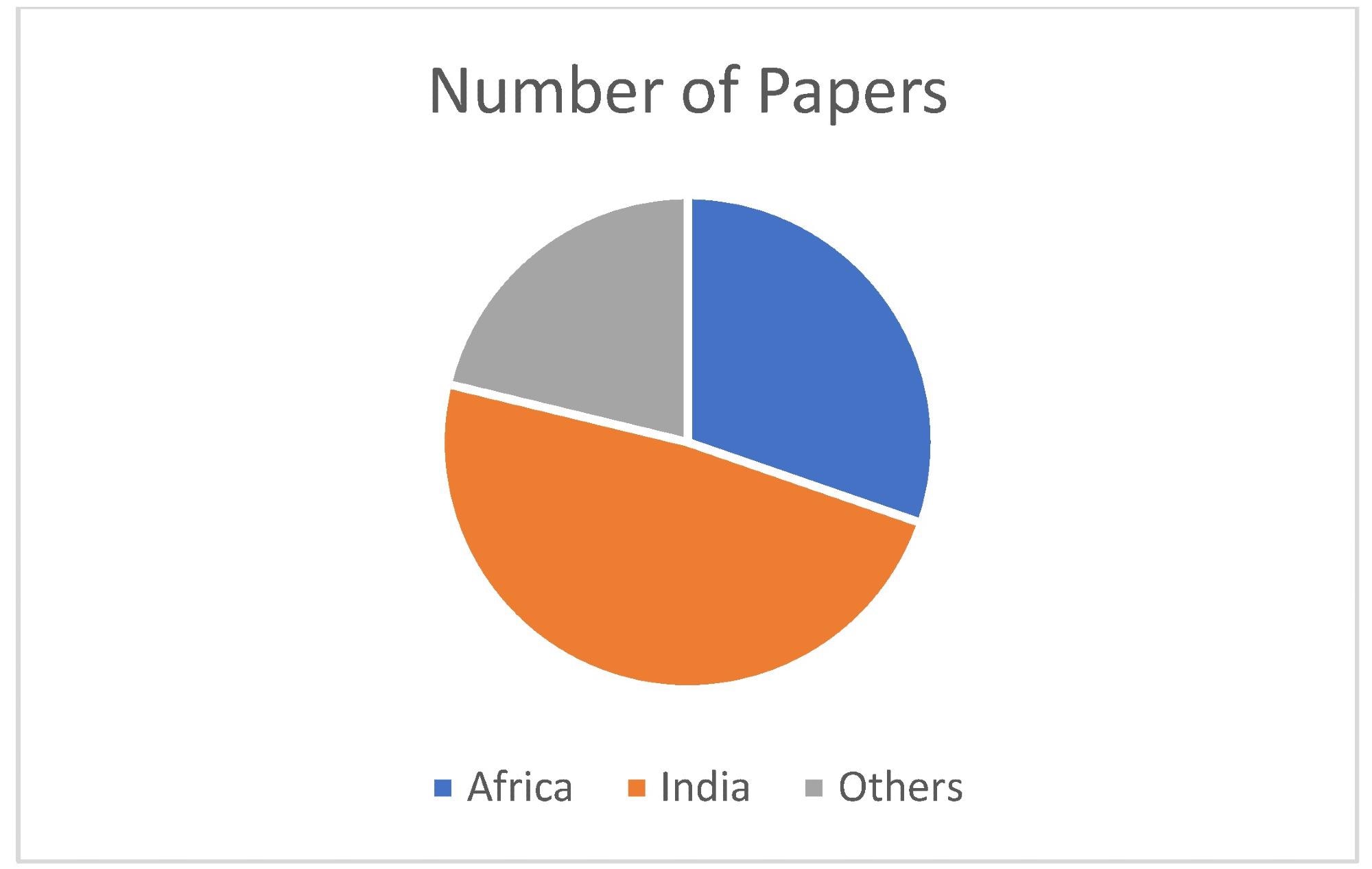

This literature study covered investigations on plastic sand bricks, blocks, and tiles from several different countries. Table 9 lists these countries and the references that go with them.

Table 9. Country of origin of studies included in this literature review. Source: Al-Sinan & Bubshait, 2022

| Reference No. |

Country |

Number |

| [10] |

Algeria |

1 |

| [11,12,13,15,16,17,18,42,43,44,48,50,51,52,53,54] |

India |

16 |

| [33] |

Philippines |

1 |

| [40,46] |

Ethiopia |

2 |

| [36] |

Egypt |

1 |

| [5,34,45,47] |

Nigeria |

4 |

| [41] |

Indonesia |

1 |

| [18] |

Paraguay |

1 |

| [55] |

Poland |

1 |

| [2] |

Rwanda |

1 |

| [37] |

Malaysia |

1 |

| [56] |

Colombia |

1 |

| [7] |

Iraq |

1 |

| [57] |

South Africa |

1 |

Figure 6 depicts the proportion of research from each nation that was included in this literature evaluation as visual analysis.

Figure 6. The proportion of studies from each country is used in this literature review. Image Credit: Al-Sinan & Bubshait, 2022

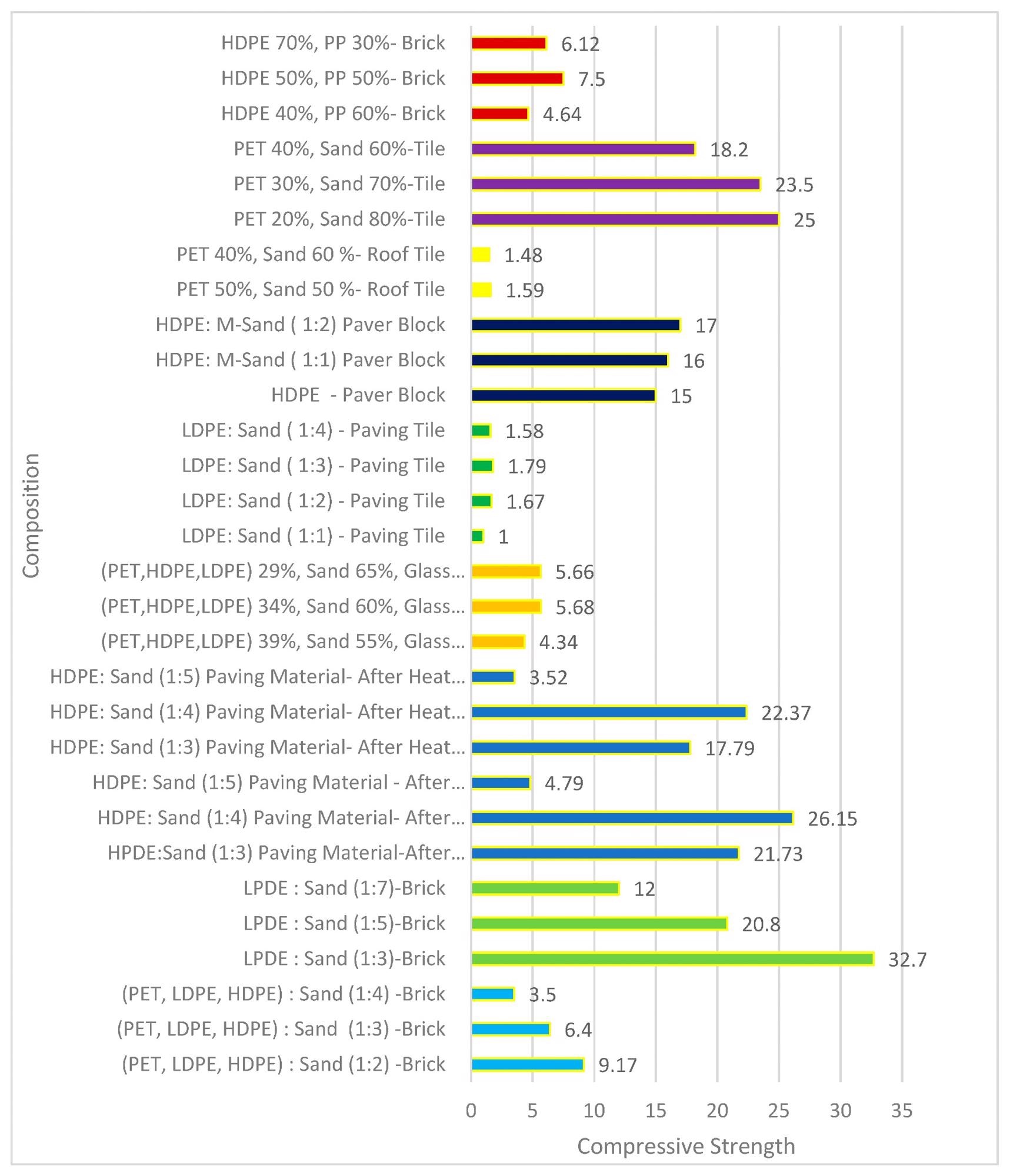

Compressive strength, water permeability, efflorescence, roughness, and conductivity of samples with varied plastic to sand ratios were investigated in the experiments. Figure 7 depicts the compressive strengths of different compositions as well as a list of research that go with them.

Figure 7. Compressive strength of various compositions. Image Credit: Dominique, et al., 2018; Suriyaa, et al., 2021; Ursua, et al., 2019; Osarumwense, et al., 2020; Susila, et al., 2019; Valarmathy, et al., 2021; Bamigboye, et al., 2019; Reta, et al., 2019; Mohan, et al., 2020

Conclusion

Due to environmental concerns, the management of plastic garbage is becoming increasingly regulated. Different organizations are addressing the issues as the world moves toward a circular economy.

The results of previously published research on the development of alternative sustainable building materials (i.e., bricks, pavers, and roofing tiles) that blend plastic waste and sand have been synthesized in this study. The following are some of the findings of this investigation:

- Plastic sand bricks could be a viable alternative for dealing with solid waste issues.

- As the plastic-to-sand ratio increased, the compressive strength fell. In comparison to normal bricks, the plastic sand bricks were lighter in weight and contained no alkali. As the plastic component of the bricks grew, the thermal conductivity of the bricks dropped.

- Plastics such as low-density polyethylene (LDPE) and polyethylene terephthalate (PET or PETE) have the potential to be employed in the manufacture of bricks and blocks.

- There is a scarcity of studies on practical elements of plastic sand bricks, such as fire resistance, cost-effectiveness, thermal conductivity, manufacturing, and commercial considerations.

- Almost all of the studies that were examined were performed on a limited scale. Moving from prototype to mass production of plastic sand bricks will necessitate a significant expenditure.

The conclusions of this research, which detail the current state of plastic sand bricks/blocks, enable researchers to focus on the future in terms of putting this innovative technology into reality and developing new initiatives to reduce plastic pollution. Plastic in construction materials has the potential to play a significant role in lowering global warming while also safeguarding the environment.

Journal Reference:

Al-Sinan, M. A. & Bubshait, A. A. (2022) Using Plastic Sand as a Construction Material toward a Circular Economy: A Review. Sustainability, 14(11), p. 6446. Available Online: https://www.mdpi.com/2071-1050/14/11/6446/htm.

References and Further Reading

- United Nations Development Programme. Plastics and Circular Economy: Community Solutions (2019) Available at: https://www.undp.org/publications/plastics-and-circular-economy-community-solutions .

- Dominique, I., et al. (2018) Recycling high-density polyethylene (HDPE) into construction materials as a key step in plastic waste reduction: Case of Kigali City. Rwanda Journal of Engineering, Science, Technology and Environment, 1. doi.org/10.4314/rjeste.v1i1.2S.

- Khadke, S., et al. (2021) Efficient Plastic Recycling and Remolding Circular Economy Using the Technology of Trust–Blockchain. Sustainability, 13, p. 9142.

- Babayemi, J.O., et al. (2019) Ensuring sustainability in plastics use in Africa: Consumption, waste generation, and projections. Environmental Sciences Europe, 31, p. 60. doi.org/10.1186/s12302-019-0254-5.

- Awoyeraa, P O & Adesina, A (2020) Plastic wastes to construction products: Status, limitations and future perspective. Case Studies in Construction Materials, 12, p. e00330. doi.org/10.1016/j.cscm.2020.e00330.

- Barcelo, L., et al. (2014) Cement and carbon emissions. Materials and Structures, 47, pp. 1055–1065. doi.org/10.1617/s11527-013-0114-5.

- Qasim, M. F., et al. (2021) Producing green concrete plastic waste and nano silica sand. Engineering, Technology & Applied Science Research, 11, pp. 7932–7937. https://doi.org/10.48084/etasr.4593.

- Filho, W. L., et al. (2021) The unsustainable use of sand: Reporting on a global problem. Sustainability, 13, p. 3356. doi.org/10.3390/su13063356.

- United Nations Environment Programme (UNEP) (2019) Sand and Sustainability: Finding New Solutions for Environmental Governance of Global Sand Resources; GRID-Geneva, United Nations Environment Programme: Geneva, Switzerland, Available online: https://wedocs.unep.org/20.500.11822/28163 .

- Guandaos, M., et al. (2016) Use of plastic waste in sand concrete. Journal of Materials and Environmental Science, 7, pp. 382–389.

- Suriyaa, M., et al. (2021) Experimental study on strength behavior of plastic sand bricks. Journal of Materials and Environmental Science, 9, pp. 6–9.

- Bansal, N & Jain, R (2020) Compression of mud brick, sand mud brick and plastic sand mud brick. International Journal of Engineering & Technology, 7, pp. 671–677. Available online: https://www.irjet.net/archives/V7/i1/IRJET-V7I1108.pdf.

- Singh, L. B., et al. (2017) Manufacturing bricks from sand and waste plastic. International Journal of Latest Technology in Engineering, Management & Applied Science, 5, pp. 426–428.

- Saeki, T & Matsuda, H (1986) Process for Producing Plastic Concrete. U.S. Patent 4613649, 23 September.

- Khandelwal, V (2019) Replacement of sand with shredded plastic in cement concrete. International Journal of Engineering & Technology, 8, pp. 946–949.

- Thirugnanasambantham, N., et al. (2017) Manufacturing and testing of plastic sand bricks. International Journal of Scientific and Engineering Research, 5, pp. 150–155.

- Aleena, J. K., et al. (2021) An experimental study on partial replacement of M-Sand with glass powder in plastic sand brick. International Journal of Research and Analytical Reviews, 8, pp. 334–348.

- Maldonado, A., et al. (2018) Setting time of ecological bricks with different percentage PET. KnE Engineering, 2, pp. 354–362. doi.org/10.18502/keg.v3i1.1440.

- Bahoriaa, B. V., et al. (2018) XRD analysis of natural sand, quarry dust, waste plastic (LDPE) to be used as a fine aggregate in concrete. Materials Today Proceedings, 5, pp. 1432–1438. doi.org/10.1016/j.matpr.2017.11.230.

- Kim, B., et al. (2019) Behaviour of sand-filled plastic bottled clay panels for sustainable homes. Journal of Building Engineering, 26, p. 100895. doi.org/10.1016/j.jobe.2019.100895.

- Gu, L & Ozbakkaloglu, T (2016) Use of recycled plastics in concrete: A critical review. Waste Management, 51, pp. 19–42. doi.org/10.1016/j.wasman.2016.03.005.

- Kamaruddin, M. A., et al. (2017) Potential use of plastic waste as construction materials: Recent progress and future prospect. IOP Conference Series: Materials Science and Engineering, 267, p. 012011.

- Almeshal, I., et al. (2020) Use of recycled plastic as fine aggregate in cementitious composites: A review. Construction and Building Materials, 253, p. 119146. doi.org/10.1016/j.conbuildmat.2020.119146.

- Babafemi, A. J., et al. (2018) Engineering properties of concrete with waste recycled plastic: A review. Sustainability, 10, p. 3875. doi.org/10.3390/su10113875.

- Mercante, I., et al. (2018) Mortar and concrete composites with recycled plastic: A review.Science and Technology of Materials, 30, pp. 69–79. doi.org/10.1016/j.stmat.2018.11.003.

- Saikia, N & de Brito, J (2012) Use of plastic waste as aggregate in cement mortar and concrete preparation: A review. Construction and Building Materials, 34, pp. 385–401. doi.org/10.1016/j.conbuildmat.2012.02.066.

- Da Silva, T. R., et al. (2021) Application of Plastic Wastes in Construction Materials: A Review Using the Concept of Life-Cycle Assessment in the Context of Recent Research for Future Perspectives. Materials, 14, p. 3549.doi.org/10.3390/ma14133549.

- Geissdoerfer, M., et al. (2017) The circular economy–A new sustainability paradigm? Journal of Cleaner Production, 143, pp. 757–768. doi.org/10.1016/j.jclepro.2016.12.048.

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions; Towards a circular economy: A Zero Waste Program for Europe. (2014) Document 52014DC0398. Available at: : https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A52014DC0398 .

- Ellen MacArthur Foundation. Towards the Circular Economy: Economic and Business Rationale for an Accelerated Transition (2013) Available at : https://ellenmacarthurfoundation.org/towards-a-circular-economy-business-rationale-for-an-accelerated-transition.

- Nikolaou, I. E., et al. (2021) Circular economy and sustainability: The past, the present and the future directions. Circular Economy and Sustainability, 1, pp. 1–20. doi.org/10.1007/s43615-021-00030-3.

- Valverde, J M & Avilés-Palacios, C (2021) Circular economy as a catalyst for progress towards the Sustainable Development Goals: A positive relationship between two self-sufficient variables. Sustainability, 13, p. 12652. doi.org/10.3390/su132212652.

- Ursua, J R S (2019) Plastic wastes, glass bottles, and paper: Eco-building materials for making sand bricks. The Journal of Natural and Allied Sciences, 3, pp. 46–52.

- Osarumwense, J. O., et al. (2020) Utilization of low density polyethylene (LDPE) plastic wastes in the production of paving tiles.Journal of Materials and Environmental Science,11, pp. 2052–2060.

- The Basics on 7 Common Types of Plastic (2022) Plastic Oceans. Available at : https://plasticoceans.org/7-types-of-plastic/.

- Tawab, O. F. A., et al. (2020) Recycling waste plastic bags as a replacement for cement in production of building bricks and concrete blocks. Journal of Waste Resources and Recycling, 1, p. 202.

- Abas, N F & Taiwo, O O (2020) Utilization of pet wastes aggregate in building construction—A review. International Journal of Recent Technology and Engineering, 9, pp. 656–663. doi.org/10.35940/ijrte.C4636.099320

- Koirala, M P & Joshi, E B R (2017) Construction sand, quality and supply management in infrastructure project. International Journal of Advances in Engineering & Scientific Research, 4, pp.1–15. doi.org/10.5281/zenodo.825068.

- Badraddin, A. K., et al. (2021) Main challenges to concrete recycling in practice. Sustainability, 13, p. 11077. doi.org/10.3390/su131911077.

- Tufa, M., et al. (2021) Study of sand-plastic composite using optimal mixture design of experiments for best compressive strength. Materials Today: Proceedings, 47, pp. 480–487. doi.org/10.1016/j.matpr.2021.05.031.

- Susila, I. M., et al. (2019) The effect of composition of plastic waste low density polyethylene (LDPE) with sand to pressure strength and density of sand/LDPE composite. IOP Conference Series: Materials Science and Engineering, 539, p. 012043. doi.org/10.1088/1757-899X/539/1/012043.

- Valarmathy, N & Sindhu, G P (2021) Comparative study on conventional HDPE paver blocks with M-Sand and bagasse ash as constituent materials. SSRG International Journal of Civil Engineering, 8, pp. 1–3. doi.org/10.14445/23488352/IJCE-V8I1P101.

- Clement, M., et al. (2019) An experimental study on brick manufactured using M-Sand, sawdust, and recycled plastic. International Journal of Innovative Research in Science, Engineering and Technology, 10, pp. 171–178.

- Chauhan, S. S., et al. (2019) Fabrication and testing of plastic sand bricks. IOP Conference Series: Materials Science and Engineering, 691, p. 012083. doi.org/10.1088/1757-899X/691/1/012083.

- Bamigboye, G. O., et al. (2019) Experimental study on the use of waste polyethylene terephthalate (PET) and river sand in roof tile production. Journal of Physics: Conference Series, 1378, p. 42105.

- Reta, Y & Mahto, S (2019) Manufacture of tiles using waste plastic and river sand. International Journal of Research, 6, pp. 335–341.

- Akinyele, J., et al. (2020 Effect of waste PET on the structural properties of burnt bricks. Scientific African, 7, p. e00301. doi.org/10.1016/j.sciaf.2020.e00301.

- Mohan, R. K., et al. (2020) Manufacturing of bricks from HDPE and PP plastic. Journal of Emerging Technologies and Innovative Research, 7, pp. 666–673.

- United Nations Environment Programme (UNEP). Africa Waste Management Outlook: Summary for Decision Makers. 2021. Available online: https://wedocs.unep.org/20.500.11822/25515 .\

- Sultan, M., et al. (2020) Utilization of waste plastic in manufacturing of plastic sand bricks. International Journal of Engineering Science and Innovative, 5, pp. 38–42.

- Chhazed, A., et al. (2019) Utilization of PET waste in plastic bricks, flexible pavement & as alternative constructional material—A review. International Journal of Applied Engineering Research, 14, pp. 616–620.

- Manjarekar, A (2019) Waste plastic bottles used in construction. International Journal of Engineering Research and Development, 7, pp. 86–91.

- Selvamani, C., et al. (2019) Preparation of bricks using sand and waste plastic bottles. International Research Journal in Advanced Engineering and Technology, 5, pp. 4341–4352.

- Parthiban, L., et al. (2018) Experimental study of plastic bricks using polyethylene wastes as partial replacement of M-Sand. International Journal of Advance Scientific Research and Engineering Trends, 4, pp. 351–353.

- Sulyman, M., et al. (2016) Utilization of recycled polyethylene terephthalate (PET) in engineering materials: A review. International Journal of Environmental Science and Technology, 7, pp. 100–108. doi.org/10.7763/IJESD.2016.V7.749.

- Sanchez-Echeverri, L. A., et al. (2021) Mechanical and market study for sand/recycled-plastic cobbles in a medium-size Colombian city. Recycling, 6, p. 17. doi.org/10.3390/recycling6010017.

- Aneke, F I & Shabangu, C (2021) Green-efficient masonry bricks produced from scrap plastic waste and foundry sand. Case Studies in Construction Materials, 4, p. e00515. doi.org/10.1016/j.cscm.2021.e00515.

- Research and Markets. Global Concrete Block and Brick Manufacturing Market Size by Product Type, By Geographic Scope And Forecast (2022) Available at : https://www.researchandmarkets.com/reports/5440575/global-concrete-block-and-brick-manufacturing?gclid=EAIaIQobChMIvMPykuH49wIVRbrVCh2qPApjEAAYAiAAEgK5M_D_BwE (accessed on 6 May).