In this interview, AZoCleantech speaks with a French research group that has been shortlisted as a finalist for the European Inventor Award 2023. Composed of five researchers, this multidisciplinary team has developed a safe and efficient method of storing hydrogen in a solid form, which is likely to play a crucial role in the ongoing fight against climate change.

The European Inventor Award 2023 is Europe’s top innovation prize that recognizes Individuals’ contributions to scientific and technology progress. What innovation led to your team becoming shortlisted for such an award?

We were shortlisted for our new technology that enables the mass storage of renewable energies.

Some of the energy types that can be stored include the following:

- The storage of hydrogen in solid form in magnesium (MgH2)

- Original additives that accelerate hydrogen absorption/desorption reactions

- Additives for high thermal conduction (Expanded natural graphite or NEG) and formation of solid compacts

- “Adiabatic” tank design allows for the reversible storage of reaction heat on a peripheral tank containing a Phase Change Metal (PCM)

- Tanks with external heat exchange, allowing heat regeneration such as waste heat recovery.

The research was initially carried out at the French National Center for Scientific Research (CNRS). After the first patent was filed, the technology was transferred to two industry partners, McPhy and JOMI-LEMAN, to commence commercialization of the product.

Image Credit: JOMI-LEMAN

As the demand for energy and resources continues to skyrocket, why is it crucial to discover innovative solutions for the challenges posed by climate change?

Carbon-free renewables are essentially intermittent. Thus, the ability to store large amounts of energy is crucial when it comes to satisfying different consumption patterns with varying demands (morning/middle of the day/evening, week). The ability to store this energy will allow us to be more flexible and adapt to consumption.

Green hydrogen is becoming a popular alternative as governments and industries try to move away from fossil fuels. What is green hydrogen, and how can it potentially be used to help achieve global decarbonization?

Green hydrogen tends to be produced via electrolysis from decarbonized electricity.

Our technology is perfectly suited to the storage of large quantities of renewable energy for a wide range of uses, e.g., domestic or industrial uses, such as chemistry (and H2 as a chemical molecule), metallurgy, cement, heavy transport (trains, ferries, trailers, etc.).

Image Credit: JOMI-LEMAN

Despite its key role in the energy transition, hydrogen is relatively hard to store and transport. What are some of the key factors that make the storage and transportation of hydrogen so difficult?

For the same mass, hydrogen (33 kWh/kg) holds three times more energy than carbon fuels, and the best lithium batteries aim for 0.3 kWh/kg. However, one bottleneck here is that hydrogen is a low-density energy carrier.

Molecular hydrogen (H2 or di-hydrogen) in a compressed state at 750 Bar, however, contains 43 kg of hydrogen per m3 of hydrogen, and in its liquid state (-253°C), it contains 70 kg of hydrogen per m3 of liquid. These two types of “compression” require significant energy (compression or liquefaction). Nonetheless, with our proposal for atomic hydrogen in magnesium, we would be able to obtain 106 kg of hydrogen per m3.

One of the main goals within the industry is the safer and more efficient storage of hydrogen. Could you please provide an overview of your novel method that facilitates this?

Our proposition allows for reversible storage and parallel (or regenerative) heat formation. Therefore, this reversible solid storage can achieve a total energy efficiency of more than 80%.

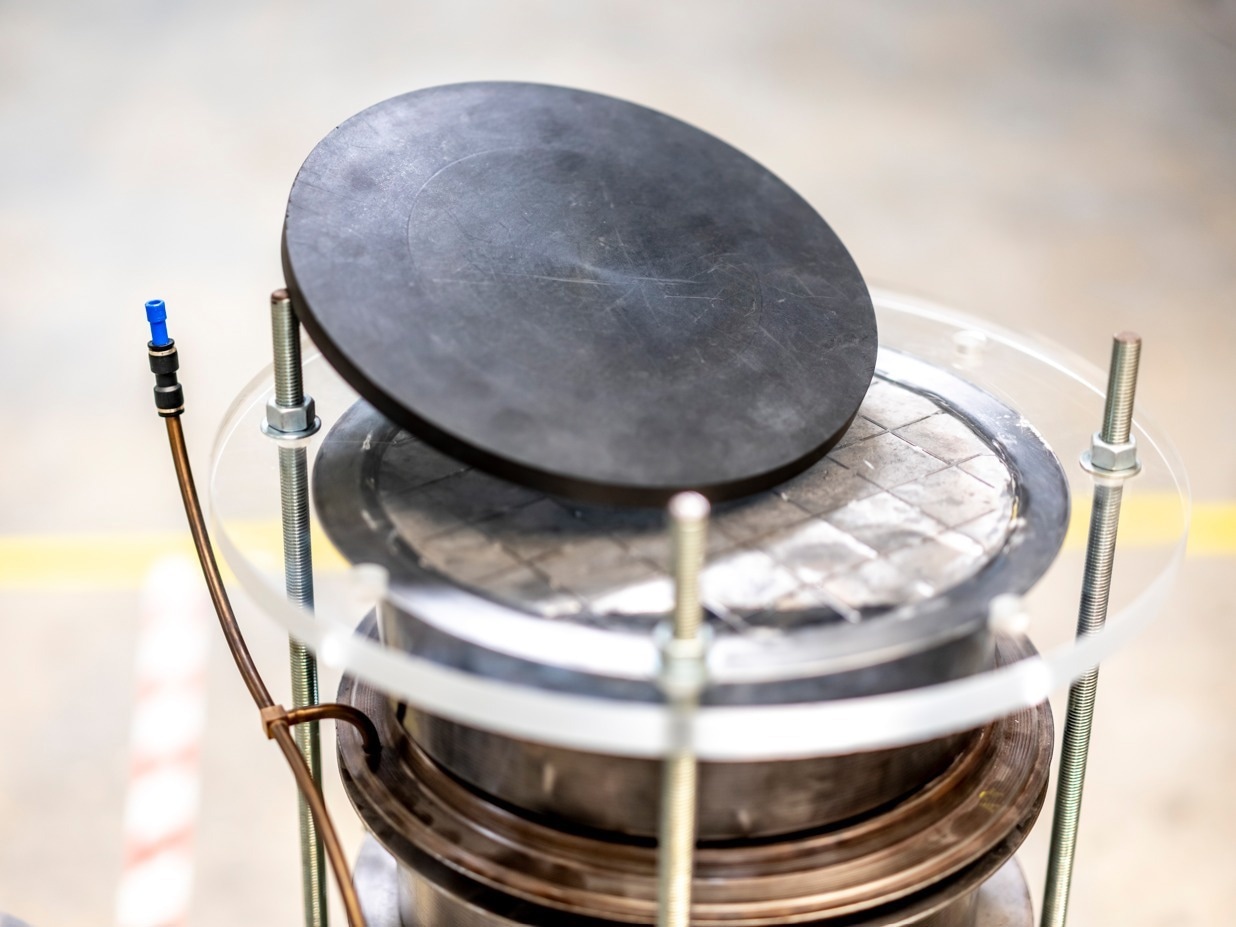

Image Credit: JOMI-LEMAN

For example, the elemental solid storage can be a basic MgH2 elemental disc with a catalyst and heat-conducting additives (NEG). The capacity of such a pellet of ~1-liter volume is about 650 N liters of hydrogen for a total pellet mass of ~1 kg. This compact is perfectly stable and safe at room temperature, and there is no reaction or release of H2 into the air. The tank containing a stack of pellets is charged at 10-15 Bar with hydrogen directly from the electrolyzer and STA supplied to the hydrogen desorber at 2-3 Bar.

Our pellets have cycled absorption/desorption up to 7400x without degrading storage capacities and reaction kinetics.

How will this innovative solution help to make green hydrogen more accessible in a world that is trying to combat climate change?

Energy storage in the form of hydrogen is the perfect answer to the production of renewable or green energy, which is intermittent. The storage can be adapted to the needs of different scales (kWh to GWh). As for MgH2, magnesium (the 7th element) is evenly distributed over the continents, is relatively inexpensive, is a known metallurgy, is totally recyclable and biocompatible, and absorbs up to 7.6wt of hydrogen, thus forming a mono-metal hydride (which is resistant to cycles).

How does this technique compare to more conventional methods of hydrogen storage?

One of the most significant benefits of the solid disk storage technique is its much-improved safety features. More conventional methods of hydrogen storage pose risks of leakage or combustion. However, this particular solid disk can be safely handled at ambient temperatures without having a reaction with the surrounding air.

Moreover, more conventional methods of hydrogen storage are energy-intensive (compression vs. liquefaction), and economic and logistical aspects can come into question when considering the distribution of the molecule. Obviously, pipeline distribution networks cannot be extended to all consumers and locations.

Our solution is to produce and store on-site, as electricity is easily and safely transported to regular production via electrolysis.

Image Credit: JOMI-LEMAN

What sectors are likely to benefit the most from this scientific advancement?

This hydrogen storage technology is applicable to a number of wide-ranging sectors.

The storage of hydrogen in solid form has two purposes: Storing energy (combustion of fuel cells) and using the clean molecule for synthetic chemistry. This concerns domestic consumption (heating) and mobility (petrol stations and, above all, industrial needs which continue to be very carbon intensive - chemicals such as ammonia and others - iron and steel industries (ore reduction and heating) float-glass, cement works…).

It is important to note that research efforts are also being made to recover the heat of the reaction from Mg↔H2.

We aim to deliver bulk hydrogen for ammonia synthesis and seawater desalination with electrolyzers connected to PV fields in desert countries.

Our proposal also meets the demand for heavy goods transportation:

- Ferry mobility; for example, in Norway, where solid storage containers can be easily provisioned (and very quickly loaded) in harbors using renewable electricity.

- Transport of very large masses of hydrogen between continents (Australia-Japan, Chile-Germany, etc.), in which the advantages of solid storage in traditional container ships is threefold: in terms of mass, energy, and most importantly, safety.

When can our readers expect to see this patent implemented in the real world, and will you be working alongside any companies to help facilitate this fabrication?

There are, in fact, five successive patents. ‘Our’ company, JOMI-LEMAN, is already being equipped with original and large-scale machines and equipment, which are self-designed. Demonstrators are also being created. The targeted production of MgH2 ranges from 30 t/year to 600 t/year in the medium term.

What would it mean for you to win the European Inventor Award, and how will this help to accelerate your research and development?

Winning such an award would be highly rewarding for the teams that have invested so much into our research; this project involved 15 years of R&D and the collaboration of more than 12 Ph.D. students.

Above all, winning this award would be a great way to showcase our efforts to decarbonize energy, which offers a vision of a more sustainable and serene future for humanity. We’re not ready for degrowth quite yet.

It will also help us to connect with new contacts and stimulate investments to amplify this technology. In these uncertain times, communication, in the broadest sense, is a lever to support future-oriented solutions.

Do you have any future plans to enhance this technology further?

The JOMI-LEMAN company is currently in the start-up process but plans to expand. New patents are in the works. Material shaping technologies will evolve for better efficiency (in terms of energy, time, and manpower). Upstream research is also interested in other hydrogen storage materials for specific targeted applications.

About the Finalists

About the Finalists

Albin Chaise - Engineer and Research Scientist at CEA LITEN

Chaise obtained his Engineer degree after studying at the School of Mechanical and Aeronautical Technologies in Poitiers. He received his Ph.D. in material physics after three years of studying the magnesium hydride used as a hydrogen storage medium and, particularly, improving the thermal conductivity of this material used in a heat exchanger.

From 2008 to 2016, Chaise continued to develop hydrogen storage in CEA (Commissariat à l’Energie Atomique et aux énergies alternatives). He worked alongside a company to scale up magnesium-based hydrogen storage technology using the present invention. With his team, he diversified the H2 storage technology by co-developing heat exchangers with ambient temperature metal hydrides.

Since 2016, Chaise has studied the hydrogen and CO2 catalytic conversion to hydrocarbons through demonstration projects like JUPITER 1000, METHYCENTRE or METHAREN in France and Europe. He is currently working on developing innovative heat-exchanger reactors to match the Power to Gas technology with the future market of hydrogen and non-fossil gases.

Chaise has authored 17 research publications and 25 patents, of which 16 address hydrogen storage in metal hydrides.

Patricia de Rango - Research Scientist, Centre National de la Recherche Scientifique (CNRS), Grenoble, France

de Rango earned her Diplôme d’Igénieur from the School of Energy and Material and her Masters in Material Sciences from Orléans University. She received her Ph.D., on the Magnetic Texturing of High-Tc Superconductors, from CNRS CRTBT and her Habilitation Doctorate from Grenoble University, in recognition of her high scientific level and original approach to physics.

She was part of a six-month fellowship with the Japan Society for the Promotion of Science (JSPS) at the Tsubuka Magnet Laboratory in Tsubuka, Japan. She was included in the three-month Hystore Technologies CE-PIAP program in Cyprus. de Rango also received a Senior Scientist position (Research Director) at CNRS in 2013.

Since 2009, she has been an expert at the International Energy Agency (IEA) working on Task 40: ‘Energy storage and conversion based on Hydrogen.’ Additionally, since 2020 she has been co-leader of the ‘Storage’ thematic axis of the Hydrogen Research Federation (FRH2). de Rango is currently a Research Scientist focusing on Material Science and a Thesis Director at the Joseph Fourier University in Grenoble Alpes University.

de Rango has authored 117 research publications in international journals, and her work has been cited over 2,400 times. From 1988 to 2008, she taught practical work in Solid Chemistry at the National School of Electrochemistry and Electrometallurgy of Grenoble (ENSEEG) at Grenoble INP. In 2012, she received the Yves Rocard award from the French Society of Physics for the innovation of ‘Hydrogen Storage into Magnesium Hydride.’

Daniel Fruchart - Expert at MgREEsource SAS, France

Fruchart earned two MSc degrees, the first in ‘Pure and Fundamental Mathematics’ from Lille University and the second in ‘Physics and Crystallography’ while studying in Grenoble, France. Fruchart was awarded the position of Senior Scientist (Research Director 1) at CNRS in 1995. From 1980 to 1984, he taught Crystallography for the Second Year Physical Engineering term at the Grenoble Institute of Technology. He was Head of the French-Spanish European Laboratory, MANES, from 1994 to 2004. He was included in the three-month Hystore Technologies CE-PIAP program in Cyprus.

In 2008, Fruchart co-founded McPhy Energy SAS and composed Research DR (Derivative Report) on Solid H-storage until the company ceased the H-storage activity in 2014. At the same time, he was an expert at JOMI-LEMAN SAS on energy transfer and materials and systems storage until 2021.

Fruchart was the founder/manager of HollyFlow-Eurl, a company that specializes in the expertise of materials and systems for energy. Since 2020, he has been an expert at MgREEsource SAS in recycling NdFeB (neodymium) magnets by hydrogen decrepitation. Alongside Michel Jehan, he researches Solid H-Storage, specifically materials and tanks, at McPhy Energy and later at JOMI-LEMAN.

Fruchart is responsible for more than 30 industrial, institutional, and internationally-based Research and Development contracts. He has published nearly 900 research papers, mostly in international peer-reviewed journals. He was a member of several board committees from 1999 to 2014 and is an IEA expert and International Atomic Energy (IAEA) advisor. In 2012, he received the Yves Rocard award from the French Society of Physics for the innovation of ‘Hydrogen Storage into Magnesium Hydride.’

His achieved patents state him as the inventor of:

- New hard magnets NdFeB metal hydrides (1985) licensed Ugimag, then sold San-Huan (China)

- Homogen granulometry hard magnet materials (1991) licensed Ugimag, then sold San-Huan (China)

- Forged hard magnet alloys for bonded magnets (1998) Rhöne6Poulence, then Sold Santoku (Japan)

- Process treatment sodium from surgenerator plant (1999)

- Magnetic thin layer deposits implanted by PAPVD for 3D recording ((2006)

- Tank for hydrogen and heat reversible storage (2008) lMcPhy.

- New efficient magnetocaloric materials (2008) Rhöne-Poulenc.

Michel Jehan - President and CEO of JOMI-LEMAN SAS, and Founder of JOMI-LEMAN

Jehan earned his bachelor's degree in the technical series from the Lemonnier Institute and his DUT in Mechanical/High-Speed Metal Cutting for Aeronautics from the Technology Institute University. He has an engineering degree in Electo-Mechanical Engineering/Physics, Metallurgy, Steel Plant Processes and Company Administration from the National School of Engineers.

He started his career in the field of non-ferrous and ferrous metals in France at VALLOUREC as a steel plant production engineer, a production manager at Nobel BOZEL (now Pechiney Electrométallurgie), and then as a Managing Director at Extrament Industrie. Jehan was recruited by a Canadian company, Timminco, as their Technical and Commercial Director, where he worked until 1991. He focused on the industrial production of calcium, strontium, and magnesium in Europe. He then became the Managing Director at INREC in Geneva, Switzerland.

He later created his own company in 1995, MCP (Metal Composite Powder) Technologies, for the granulation of calcium and magnesium and later went into the industrial production of magnesium granules and powders for hot metal desulfurization in steel plants and magnesium supplies for chemical Grignard reagents for medicines, synthetic flavor, and fragrances.

In January 2008, he founded McPhy Energy with Daniel Fruchart and was its CEO, CTO, and Board Member until he retired from the company in November 2013. Since 2013, he has been President and CEO of JOMI-LEMAN SAS and is the founder of JOMI-LEMAN, consulting on metallurgy and energy storage. He was also President of the association ALPHEA in Lorraine.

Jehan is responsible for seven publications on the principles and uses of magnesium and co-authored with other members of his team.

Among his achieved patents, four state him as the inventor of:

- The AFFIVAL process (1980). (Production of cored wires for liquid steel treatments).

- A continuous casting production process of magnesium allows for anodes' cathodic protection (1995 – private patent).

- A new electrochemical process reactor for direct hydrogen large-scale production (2014).

- A new electrochemical process for electricity storage (2015).

In 2012, he received the Yves Rocard award from the French Society of Physics for the innovation of ‘Hydrogen Storage into Magnesium Hydride.’ Jehan also received the French National Special prize of the jury: « Chéreau-Lavet 2011 » Reward of the year as a Creative Engineer and inventor showing numerous patents and a lot of creativity owing to the creation of jobs for many employees during his career

Nataliya Skryabina - Director of Research Department, JOMI-LEMAN SAS, France

Skryabina earned her MSc in Physics from Perm State University (PSU), Perm, Russia, and her Ph.D. from the Polytechnic Institute in Voronezh, Russia. She obtained her Habilitation Doctorate on ‘The Nature of the Deformation Effects in Metal-Hydrogen Systems’ from PSU.

She started her physics career as a Senior Research Associate and Manager of the Laboratory responsible for Structural Research at the Republic Engineer Centre of Powder Metallurgy in Perm, Russia, in 1984. From there, she became a Senior Research Associate and Head of the Scientific sector in the X-Ray Diffraction Lab at the Mining Institute of the Russian Academy of Sciences in 1989.

During her 21 years at PSU, Skryabina held positions including Leader of the X-Ray Diffraction Laboratory, Associate Professor, and Professor in the Departments of Physics and Chemistry, a role she held from 2000 until her retirement in 2016. From January 2003 to August 2005, June 2005 to October 2006, and June 2007 to October 2008, she was an Invited Scientist at CNRS, Grenoble, France.

Since 1981, Skryabina has published one monograph and close to 330 papers in Russian and International Scientific Journals. She was a member of the Editorial Board of the International Scientific Journal for Alternative Energy and Ecology (2002-2014). She received 14 research grants from 1994 to 2014. Skryabina has co-authored four patents; all addressed to metal-hydrogen storage systems.

About the European Inventor Award

The European Inventor Award is one of Europe's most prestigious innovation prizes. Launched by the EPO in 2006, the award honors individual and team solutions to some of the biggest challenges of our time. The finalists and winners are selected by an independent jury comprising former Award finalists. Together, they examine the proposals for their contribution toward technical progress, social and sustainable development, and economic prosperity.

About the EPO

With 6,300 staff members, the European Patent Office (EPO) is one of the largest public service institutions in Europe. Headquartered in Munich with offices in Berlin, Brussels, The Hague, and Vienna, the EPO was founded with the aim of strengthening cooperation on patents in Europe. Through the EPO's centralized patent granting procedure, inventors are able to obtain high-quality patent protection in up to 44 countries, covering a market of some 700 million people. The EPO is also the world's leading authority in patent information and patent searching.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.