Environmental and social consciousness is quickly becoming the defining characteristic of a sustainable tire industry. Tires produce pollution throughout their entire life cycle. To promote sustainability and ensure the utilization of carbon-free materials along with the development of end-of-life tire management policies, WBCSD’s Tire Industry Project (TIP) is playing a crucial role. This article provides an overview of the project, its goals, and the crucial plans being devised and implemented.

Image Credit: overcrew/Shutterstock.com

What is the Tire Industry Project (TIP)?

The Tire Industry Project (TIP), founded in 2005 by the World Business Council for Sustainable Development (WBCSD), is the leading worldwide platform for tire manufacturers to discuss sustainability concerns.

To foster an ecologically sustainable future, TIP's goal is to effectively identify and investigate any possible public health and environmental hazards linked to the life cycle impacts of tires. TIP has the resources to collaborate with governments worldwide to ensure ecologically sound remedies for end-of-life tire management, tire and road wear particles, and renewable natural rubber.

The primary objective of the Tire Industry Project is to understand and mitigate the numerous ecological effects deeply connected to the lifecycle of tires. This involves examining multiple phases, including mining raw materials, tire fabrication processes, utilization and efficacy, and end-of-life management.

Environmental Sustainability Challenges Surrounding Tire Industry

Several sustainability issues arise during the entire lifecycle of the tire industry. From the process of raw materials extraction to the end-of-life management process, several environmental issues are prevalent.

The production of tires generates a massive quantity of solid refuse from various sources. During the manufacturing process of tires, volatile organic compounds (VOC) are primarily emitted. Compounding results in VOC emission due to healing substances, incubators for startups, and the blending process. In various situations, liquid waste is developed with the help of impurities such as anti-tack agents, oil and grease, and elastomers.

As per the recent article published in Environmental Pollution, the most recent risk analysis performed by EU authorities discovered that tire recycling results in the discharge of 16,000 tons of microplastics annually and that the total amount of plastic particles will ultimately constitute a threat to the environment.

Abrasion of particulates and chemical leakage during various phases of tire life highlight the need to comprehend the dangers of polymeric substances, as well as the substances they contain and their transformation byproducts.

Identification of Environmental Factors by TIP

The need to tackle ecological and social effects in the tire industry has resulted in a greater emphasis on logistics, particularly the natural rubber chain of supply. The tire business utilizes 70 percent of all natural rubber manufactured worldwide. Through the Global Platform for Sustainable Natural Rubber (GPSNR), TIP partners strive to guarantee that vendors meet human rights and environmental standards.

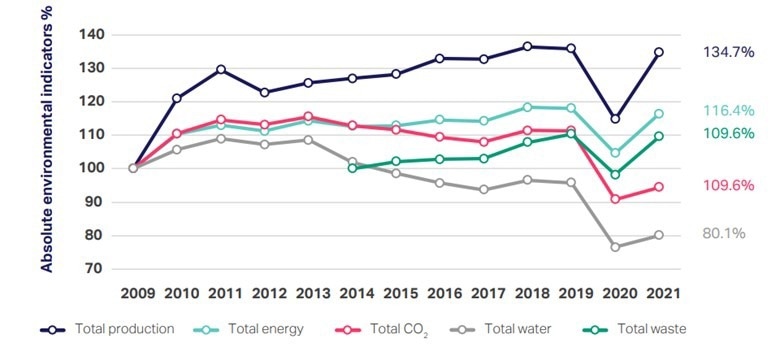

The experts at TIP issued a comprehensive report focused on identifying key environmental parameters essential for sustainable development. The significant factors highlighted are CO2 emissions, ISO 14001 site certification, energy consumption, and water with drawls.

The report indicates a decreasing trend in CO2, water, and energy emissions since 2009. This pattern was halted by the COVID-19 pandemic in 2019 and 2020, resulting in a 21 percent drop in overall manufacturing year-over-year.

Figure Depicting Absolute Values of Key Environmental Indicators Highlighted by TIP. Image Credit: World Business Council

for Sustainable Development

The most significant efficiency improvement has been highlighted for water. The intensity of water dropped by 41% between 2009 and 2021. A total of 232, or 96%, of the 241 production plants managed by TIP members in 2021 were ISO 14001-certified.

The report also mentions novel methods and strategies to improve energy efficiencies and reduce CO2 emissions. TIP focuses on compressed air systems optimization, novel modified heat pumps at manufacturing sites, swapping natural gas for hydrogen gas, and superior performance and control of tire curing apparatus.

Composing a Sustainable Development Goals (SDG)-Based Approach

The eleven-member TIP companies developed a strategic road map to promote the necessary transformation for achieving the SDGs. The Tire Industry Partnership highlighted seven possibilities where the tire industry can have a profound effect while contributing to the Sustainable Development Goals across three major themes: supply chain, operations, and products and services.

It concentrates on expanding and speeding up activities to achieve an impartial, just, and environmentally sustainable natural rubber value chain that ensures decent labor conditions and respects the rights of individuals. Operations discipline could aid in decarbonizing processes, reducing greenhouse gases, and ensuring the sustainable use of organic resources by devising sustainable methods.

End-of-Life Tire Management Strategy

End-of-life tires (ELTs) and their components are a cost-effective and versatile asset for a sustainable economy.

Effective ELT administration processes encourage the re-use of ELTs while minimizing unauthorized tire disposal. TIP conducted seminars with the US Tire Manufacturers Association (USTMA), the European Tire and Rubber Manufacturers Association (ETRMA), and the China Tire Recycling Association (CTRA), and subsequently published a comprehensive report.

According to the report, corporations in the US recovered nearly 76% of ELTs for use in goods such as rubber-modified concrete, vehicle components, and tire-derived gasoline. This was a decline from 2013's peak recycling rate of 96%.

The complicated web of state laws inhibits the nationwide duplication of operations, requirements, and compositions, impeding the expansion of ELT markets in the US. According to TIP, steps are required across the value chain to promote ELT administration by, for example, encouraging capacity for recycling in tire design, scheduling research priorities, and enabling innovative thinking and entrepreneurship by providing funds and exchanging knowledge. TIP evaluates established techniques and criteria for enhanced tire value chain sustainability evaluation and surveillance.

Sustainable Tire Materials

TIP has researched and devised strategies for the utilization of novel tire materials. Cardno ChemRisk assisted the Tire Industry Project (TIP) in producing cryogenically milled tire tread (CMTT) particles. Initially, the tire's exterior can be cleansed with pneumatic air or a cloth.

Using an appropriate cutting instrument, the tread was cut off from the top of the top belt or the protective layer of undamaged tires. The tread sections were then sent to Pulva Corporation to produce CMTT. This CMTT generation method minimizes possible external influences, such as the generation of harmful byproducts, and minimizes contamination.

TIP has also assisted the Organization for Economic Cooperation and Development (OECD) with a report designed to assist in bridging the gap between suitable safety and ecological risk evaluation techniques and frameworks along with the swift development of nanotechnology for tire processing.

Nanomaterials offer possibilities for ingenuity in tire production, enhancing the ecological viability and economic efficacy of the tire industry and the transportation sector. They have been employed in tires to reduce tire rolling resistance, reducing petroleum consumption and greenhouse gas emissions while ensuring superior tire wear resistance, traction, and road adhesion.

Market Analysis

According to the most recent report by Bonafide Research, the global tire market will be worth USD 339.85 billion by 2027, with a CAGR of 6.75 percent. Over the forecast period, the Middle East & Africa region is anticipated to experience the highest CAGR of 9.98%, resulting in a market size of USD 26.64 billion.

In 2022, the global tire market reached 2,321,3 Million units per the market analysis published by IMARC Group.

IMARC Group forecasts that the market will reach 2,741,2 Million Units by 2028, expanding at a compound annual growth rate (CAGR) of 2.88% from 2023 to 2028.

In short, TIP is working tirelessly to boost the sustainable manufacturing of tires and is ensuring thorough research in every sector, including tire and road wear particles (TRWP), sustainable materials, and SDG-based strategies.

All such steps and the novel breakthrough achieved in academia ensure a sustainable, carbon-free future for the tire manufacturing sector.

References and Further Reading

Bonafide Research and Marketing Pvt. Ltd. (2022) Global Tire Market to be valued at USD 339.85 Billion by 2027 growing at 6.75%: Bonafide Research. [Online] Available at: https://www.globenewswire.com/en/news-release/2023/04/06/2642668/0/en/Global-Tire-Market-to-be-valued-at-USD-339-85-Billion-by-2027-growing-at-6-75-Bonafide-Research.html

Trudsø, L. et. al. (2022). The need for environmental regulation of tires: Challenges and recommendations. Environmental Pollution, 311, 119974. Available at: https://doi.org/10.1016/j.envpol.2022.119974

IMARC Impactful Insights (2022) Tire Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2023-2028. [Online] Available at: https://www.imarcgroup.com/tyre-manufacturing-plant

TIP (WBCSD) (2022) Environmental Key Performance Indicators for Tire Manufacturing 2009-2021. [Online] Available at: https://www.wbcsd.org/download/file/15553

TIP (WBSCD) (2022) Perspectives on End-of-Life Tire (ELT) Management: Challenges and potential solutions in the US, Europe and China. [Online] Available at: https://www.wbcsd.org/download/file/15889

TIP (2021) Toward a more sustainable use of nanomaterials in tires. [Online] Available at: https://www.wbcsd.org/Sector-Projects/Tire-Industry-Project/News/Toward-a-more-sustainable-use-of-nanomaterials-in-tires

TIP (2022) Tire and Road Wear Particles (TRWP) and other materials research. [Online] Available at: https://www.wbcsd.org/Sector-Projects/Tire-Industry-Project/Resources/Tire-and-Road-Wear-Particles-TRWP-and-other-Material-Research

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.