An experimental gas turbine simulator equipped with an ultra low-emissions combustion technology called low-swirl injector, or LSI, has been tested successfully using pure hydrogen as a fuel – a milestone that indicates a potential to help eliminate millions of tons of carbon dioxide and thousands of tons of NOx from power plants each year.

Introduction

The LSI (low-swirl injector) technology was developed by Robert Cheng of the U.S. Department of Energy’s Lawrence Berkeley National Laboratory. In 2007 the injector won a research and development award from R&D magazine as one of the top 100 new technologies of the year.

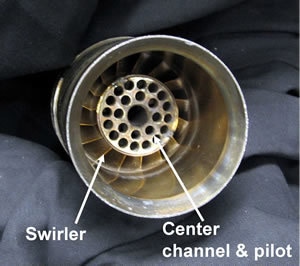

Figure 1. The figure demonstrates a prototype of the low-swirl injector. Fuel flows through the openings of the center channel. This simple design creates the low-swirl flow, with lower emissions of NOx as the result of this process.

Near-Zero Emissions of Nitrogen Oxides

The LSI holds great promise for the industry due to the near-zero-emissions of nitrogen oxides. These gases are emitted during the combustion of fuels such as natural gas during the production of electricity. Nitrogen oxides, or NOx, are greenhouse gases, as well as the main components of the smog.

The Department of Energy’s Office of Electricity Delivery and Energy Reliability initially funded the development of the LSI for use in industrial gas turbines for on-site (i.e. distributed) electricity production. This research was intended to develop a natural gas-burning turbine using the LSI’s ability to substantially reduce the otherwise high NOx emissions.

Low-Swirl Injector Technology

Cheng, David Littlejohn, Kenneth Smith, and Wazeem Nazeer from Solar Turbines Inc. of San Diego adapted the low-swirl injector technology to the Taurus 70 gas turbine that can produce about seven megawatts of electricity. The team’s effort garnered them the R&D 100 honor. This reward is continuing the LSI development for renewable fuels available from landfills, carbon-neutral fuels from organic waste treatments, and fuels from industrial processes such as petroleum refining.

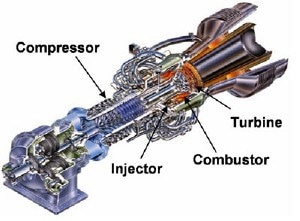

Figure 2. A cutaway view of Solar Turbines' Taurus 70 engine. The research team adapted the low swirl injector for use in this technology, which is similar to a jet engine but is used to generate electricity in power plants on the ground.

“This is a kind of rocket science,” says Cheng, who notes that these turbines, which are being used to produce electricity by burning gaseous fuels, are similar in operating principle to turbines that propel jet airplanes.

Using Hydrogen as Fuel

Another project where the LSI is being tested for its ability to burn syngas (a mixture of hydrogen and carbon monoxide) and hydrogen fuels in an advanced IGCC plant (Integrated Gasification Combined Cycle) is called FutureGen. FutureGen was started and later suddenly terminated due to financial difficulties back in 2015.

FutureGen was planned to be the world’s first near-zero-emissions coal power plant. The FutureGen plant was intended to produce hydrogen from gasification of coal and sequester the carbon dioxide generated by the process. The LSI was one of several combustion technologies being evaluated for use in the 200+- megawatt utility-size hydrogen turbine that was planned to be a key component of the FutureGen plant.

The collaboration between the Berkeley Lab and the National Energy Technology Laboratory (NETL) in Morgantown, WV, achieved the milestone of successfully test-firing an LSI unit using pure hydrogen as its fuel.

Eliminating Millions of Tons of Greenhouse Gases from Power Plants each Year

Because the LSI is a simple and cost-effective technology that can burn a variety of fuels, it could help to eliminate millions of tons of carbon dioxide and thousands of tons of NOx from power plants each year.

In a letter of support to the R&D 100 selection committee, Leonard Angello, manager of Combustion Turbine Technology for the Electric Power Research Institute, wrote:

I am impressed by the potential of this device as a critical enabling technology for the next generation coal-based Integrated Gasification Combined Cycle power plants with CO2 capture…This application holds promise for the gas turbines in IGCC power plants that operate on high-hydrogen-content syngas fuels or pure hydrogen.

Leonard Angello, Manager of Combustion Turbine Technology, Electric Power Research Institute

How the LSI works

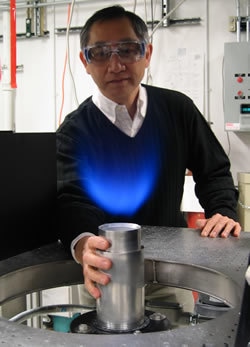

The low swirl injector is a mechanically simple device with fixed parts that imparts a mild spin to the gaseous fuel and air mixture, causing the mixture to spread out. The flame is stabilized within the spreading flow just beyond the exit of the burner. Not only is the flame stable, but it also burns at a lower temperature than that of conventional burners.

The production of nitrogen oxides is highly temperature-dependent, and the lower temperature of the flame reduces emissions of nitrogen oxides to very low levels.

Figure 3. Robert Cheng views an LSI flame. He is touching the burner, demonstrating that it stays cool because the flame is completely lifted from its body.

The LSI principle defies conventional approaches. Combustion experts worldwide are just beginning to embrace this counter-intuitive idea. Principles from turbulent fluid mechanics, thermodynamics, and flame chemistry are all required to explain the science underlying this combustion phenomenon.

Cheng, Solar Turbines Inc., San Diego

Low-Swirl Injector Releases Lower Levels of NOx than Conventional Turbines

Natural gas-burning turbines with the low-swirl injector emit an order of magnitude lower levels of NOx than conventional turbines. Tests at the Berkeley Lab and Solar Turbines showed that the burners with the LSI emit 2 parts per million of NOx (corrected to 15% oxygen). This is over five times less than conventional burners.

Benefits of the LSI Technology

A more significant benefit of the LSI technology is its ability to burn a variety of different fuels from natural gas to hydrogen. Also, undoubtedly, there is an ease to incorporate it into the current gas turbine design — extensive redesign of the turbine is not needed. The LSI is being designed as a drop-in component for gas-burning turbine power plants.

Further Information

This technology is available for license for gas turbines and certain other fields of use. For information, go to https://www.lbl.gov/.

Sources and Further Reading

This article was updated on 24th February, 2020.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.