Article updated on 17th April 2020

Sergi Lopez Roig / Shutterstock

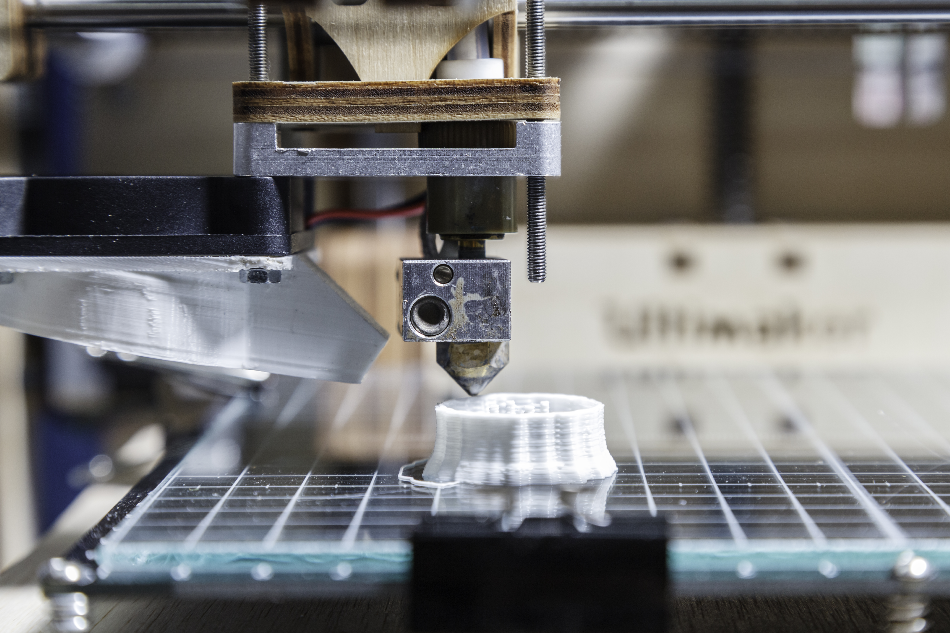

3D printing has the potential to be a clean technology, but it is far too soon to claim it is entirely clean. From a consumer point of view, 3D printing represents a future reduction in manufacturing and energy costs; instead of ordering something online and expending cost on transport and delivery, a 3D printer can produce the product at home. This is a valid argument but does not represent the modern reality.

Most 3D printers are industrial with home consumer models priced out of reach to the average buyer. There are also raw material factors to be considered. Whilst time and energy are saved in production costs, some of the materials 3D printers use are not always recyclable. Add to this the fact that little quantitative research exists to show 3D printing to be a clean technology.

Clean 3D Printing

Every new manufacturing technology should be assessed for environmental sustainability. Clean technology is defined in terms of its lifecycle, the greenhouse gas emissions produced, whether it causes air pollution, the use of toxic chemicals and whether or not it uses non-renewable resources. 3D printing is an additive manufacturing technique, meaning the parts produced often require additional processing to meet the correct dimensions and appearance of the final product.

At the moment 3D printing is not scaled to an industrial level, so it consumes resources that generate additional environmental problems. To be a truly clean technology, 3D printing would have to replace conventional manufacturing as a whole.

However, we cannot dismiss the potential impact 3D printing could have as a clean technology. Additive manufacturing allows us to produce complex shapes and parts that traditional manufacturing struggles to achieve. For example, 3D printing can produce specialized cabin components for passenger jets using lightweight materials. This reduces the weight of the overall aircraft which in turn reduces the amount of aviation fuel required for flights thus lessening the environmental impact of greenhouse gas emissions.

On-demand production is another potential benefit of 3D printing often cited by environmentalists. Instead of expending time and fuel on delivering a product ordered online, the retailer could transmit the specifications directly to the consumer’s home 3D printer which would then manufacture their order immediately. Yet this method could only be considered clean if the raw materials used to manufacture the product were 100% recyclable.

Many scientists believe on-demand production and endless customization could lead to more throw-away consumer products. There is also a lack of qualitative research to suggest the emissions of tiny plastic particles produced by 3D printers are not harmful to humans.

3D printing currently uses 4 main processes;

- Thermoplastic extrusion

- Inkjet

- Photopolymer

- Laser Sintering

Each process has advantages over traditional manufacturing, but none could be classed as entirely clean. Thermoplastic extrusion uses easily recyclable plastics like polyethylene terephthalate, but it also uses acrylonitrile butadiene styrene which is not. Inkjet saves energy on batch printing and doesn’t produce a lot of waste, but the method makes the printing of consumer goods commercially unviable. Photopolymer printing would work if used at the industrial scale because it uses liquid polymers with batch printing; a method associated with high energy efficiency.

However, it also uses solidified polymers (non-recyclable) and toxic materials. Laser sintering is only viable if used at the industrial scale. Whilst it is adapted to metals, ceramics, thermoplastics, and glass, all the plastic is non-recyclable and goes to landfills.

Yet whilst it is too soon to call 3D printing a clean technology, it has positively impacted the environment in unexpected ways. Less then 1% of the world’s water is unpolluted and fit for drinking. The introduction of 3D printing in the water industry has enabled the US Department of Energy (DOE) to begin planning entirely new desalination technology. In partnership with General Electric (GE), the DOE plan to use 3D printed turbines to form a ‘hyper cooling loop’ through a compressed combination of air, salt, and water. As the salt freezes it will separate from the ice providing potable water upon thaw. These large scale efforts could prove crucial considering water scarcity in developing countries. Employing the technology at an industrial scale could also help the cleaning efforts of contaminated water supplies around the world.

Would 3D Printing Make Manufacturing Cleaner?

Yes, but with current methods, only at the industrial batch scale. There is a potential for localization in manufacturing, reducing transport and the need for fossil fuel consumption. There is also the potential for greater availability of spare parts for complex machinery. As yet though, there is no financial incentive for manufacturers to produce digital designs for the consumer to allow them to ‘print’ their product off at home. Home 3D printers are currently more for the hobbyist with the environmental benefits negated by a lack of incentive by industrial manufacturers to adopt the technology.

References

- How 3D printing is increasing access to clean water - 3D Print – 19/04/19 https://3dprint.com/241702/how-3d-printing-is-increasing-access-to-clean-water/

- Cellink announces new 6 head printhead 3D bioplatform – 3D Printing Industry – 09/09/19 https://3dprintingindustry.com/news/cellink-announces-new-six-printhead-3d-bioprinting-platform-161329/

- Is 3D printing really a clean technology? – AZO Clean Tech - 05/07/19 https://www.azocleantech.com/article.aspx?ArticleID=908

- It’s too soon to call 3D printing a green technology – Green Biz – 18/09/18 https://www.greenbiz.com/article/its-too-soon-call-3d-printing-green-technology

- 3D Printing & Industrial Ecology - Wiley Online Library – Journal of Industrial Ecology – 05/10/17 https://onlinelibrary.wiley.com/doi/full/10.1111/jiec.12669

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.