Mar 26 2008

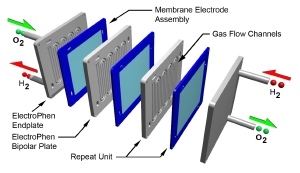

Fuel cell materials company Bac2 will launch its first standard product, blank bipolar plates for polymer electrolyte membrane (PEM) fuel cells, at the Fuel Cell Pavilion, Hall 13, during Hannover Messe 2008.

Bipolar plates make up to 30% of the cost of a PEM fuel cell stack. ElectroPhen plates offer substantial cost savings without compromising performance.

Bipolar plates make up to 30% of the cost of a PEM fuel cell stack. ElectroPhen plates offer substantial cost savings without compromising performance.

The plates, which are based on Bac2's unique conductive polymer, ElectroPhen, can be machined more simply than metal plates, making them ideal for fuel cell prototyping and development work. Each plate measures 300mm x 200mm x 3mm and its conductivity easily exceeds US Department of Energy specifications for use in automotive applications. Up to 100 plates can be ordered on 7-day delivery. It is anticipated that customers will purchase blank plates for fuel cell stack evaluation before migrating quickly to custom-molded ElectroPhen plates to take maximum advantage of the material's performance and low cost in mass production.

Bipolar plates make up to 30% of the cost of a PEM fuel cell stack. ElectroPhen plates offer substantial cost savings without compromising performance. The material has a raw state conductivity one billion times higher than commonly used resin binders, which means that no post-processing, such as extreme temperature or surface machining, is required to meet conductivity goals. ElectroPhen plates are easily molded and economical to produce in high volume. The material can be customised with plasticizers, reinforcers, and conductive filler, allowing fine-tuning of its characteristics for specific applications. ElectroPhen is thermally stable, resilient to temperature and inert towards fuel cell catalysts and membranes. It cures at room temperature and its basic raw materials are widely available from major chemical suppliers.