Mar 1 2011

Researchers at the Germany-based Fraunhofer Institute for Solar Energy Systems have successfully achieved new peak efficiencies for silicon solar cells that can be applied easily over larger areas.

The researchers have demonstrated that it will be possible to achieve 20% efficiency in a few years using advanced cell structures.

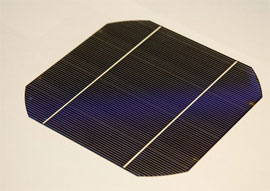

Since more than 80% of the solar cells fabricated currently, are based on crystalline silicon, the focus of the industry is on the optimization of the cost of silicon solar cells, otherwise known as the “workhorse” of photovoltaics.

CRYSTALLINE SOLAR CELLS

CRYSTALLINE SOLAR CELLS

Today only about 14% to 19% of incident solar energy is converted into electricity using silicon solar cells. With research, it will be possible to reach the 20% efficiency mark. Additionally, with incorporation of research results in the production process, concurrent with Germany’s accelerated market development, will aid in further reducing the costs of photovoltaic electricity.

The advanced cell structures differ due to the type of silicon base and the thin emitter, which is capable of collecting the electrical charge carriers. Christian Schmiga, the project leader for high-efficiency silicon solar cells at Fraunhofer, explained that dissimilar procedures were employed for processing the emitter layer. Phosphorous diffusion was used for the n-emitter layer of the p-type solar cells and boron diffusion and aluminum alloying for the p-emitter layer of the n-type of solar cells.

The researchers achieved 19.3% efficiency by using an aluminum-alloyed emitter on the n-type solar cell and 19.6% efficiency by using a boron diffused emitter with a passive surface on an n-type silicon solar cell. A crucial result was the 19.6% efficiency achieved by using a phosphorus diffused emitter on the p-type solar cell using the patented laser-fired contact (LFC) technology.