Empa, an interdisciplinary research and services institution, declared that the initial outcomes of the woven polymer electrode formulated by it has indicated hopeful results showing that the new material has the potential to replace the present indium tin oxide coatings.

The traditional silicon-based solar cells available in the market are found to be unsuitable for producing supple, thin-film solar cells, which incorporates flexible, and transparent electrodes to collect and carry the collected power. Though indium tin oxide (ITO) offers a viable alternative, its cost makes it unviable for use in large solar cell applications. The Indium-free transparent oxides available in the market are becoming scarce due to an increased demand for them. In the process the materials, such as carbon nanotubes also known as graphene and conductive polymers are currently being studied. The problem of fragility continues to be the biggest disadvantage and the efforts are on to produce a supple yet secure type of conductive substrates cost- effectively.

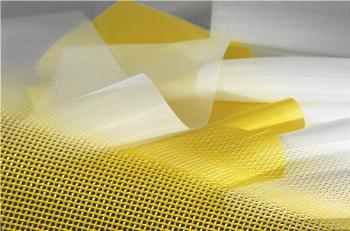

Flexible precision fabric which, in cooperation with the Swiss company Sefar AG, was developed into an electrode for thin-film solar cells

Flexible precision fabric which, in cooperation with the Swiss company Sefar AG, was developed into an electrode for thin-film solar cells

Empa in association with Sefar has developed the translucent flexible woven polymer and the development project has received financial support from the Swiss Commission for Technology and Innovation (CTI). Sefar with its expertise in precision fabrics has manufactured the woven polymer in large quantities cost -effectively through a roll to roll process. The metal wires are wound into the material to make it electrically conductive. In the next process, the woven material is implanted inside a static plastic layer ensuring to keep the metal filaments exposed to sustain its electrical conductivity quality.

The newly produced electrode remains flexible while retaining its transparent and firm attributes. A series of coatings applied by Empa researchers over the new substrate has produced a new organic solar cell with comparable efficiency of a normal ITO based solar cell. The new woven electrode continues to remain more stable when twisted when compared to other flexible plastic substrates that use a slim coating of conductive ITO.