Mohamed Halabi, a researcher of Eindhoven University of Technology, has presented a proof-of-principle to establish the feasibility of producing quality hydrogen from natural gas. The newly developed technology will allow the production of hydrogen by deploying a refined technique at comparatively low level temperatures without discharging carbon dioxide into the air.

Presently, hydrogen is produced from natural gas through a steam reforming process. The complicated process operates using high temperatures up to 850°C and need pressure levels up to 25 bar. The process is performed in multistage operations utilizing separation and purification units. Furthermore, during the post-processing procedures huge quantity of carbon dioxide needs to be treated.

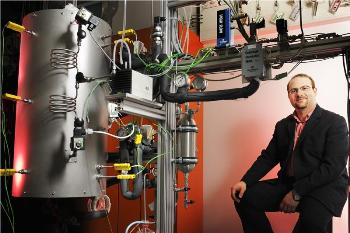

Eindhoven University researcher Mohamed Halabi at his research set-up

Eindhoven University researcher Mohamed Halabi at his research set-up

Halabi functioning in close association with the Energy Research Centre of the Netherlands (ECN) has utilized a new and better technology known as “sorption enhanced catalytic reforming of methane,” by deploying new catalyst/sorbent materials. He demonstrated the process by utilizing a packed bed reactor employing a Rhodium-based catalyst and a Hydrotalcite-based sorbent as materials in the system.

The process generated pure hydrogen with low level of carbon dioxide impurities measuring lower than 100 ppm on the active catalyst and achieving a fuel conversion efficiency of more than 99.5% with a temperature ranging from 400°C to 500°C and a pressure of 4.5 bar. The carbon dioxide produced along with it was completely adsorbed on the sorbent thus stopping the release of carbon dioxide emissions into the air.

Hydrogen is currently utilized as a raw material in the petrochemical industry and is anticipated to play a greater role as a non-polluting, clean and effective energy carrier in the future.