Researchers from the School of Arts and Sciences and School of Engineering at Tufts University have found out that single atoms in a metal alloy possess an ability to catalyze hydrogenation reactions.

single-atom alloy catalysts for hydrogenation reactions

single-atom alloy catalysts for hydrogenation reactions

Hydrogenation is the process of adding hydrogen atoms to organic compounds and it plays a major role in the pharmaceutical, petrochemical and food industries. The process requires a catalyst like alloy or metal to bind the hydrogen atoms with other molecules. However, it is complex to produce alloys that act as hydrogenation catalysts.

Tufts scientists revealed that when individual atoms of palladium, a costly precious metal, are added to copper, a cheaper material, a single atom alloy is produced, which is ideal for hydrogen-related reactions. Usually, industrial processes utilize small amounts of precious metal, which is 5 to 10 nm wide, to produce a catalyst. The Tufts team has dispersed individual atoms of palladium having a width of half a nanometer on the copper surface. This method provides higher cost savings.

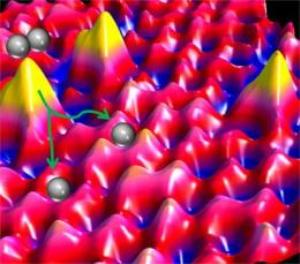

The team heated small quantities of the precious metal to about 1,000°C. The single atoms evaporated and implanted on the copper surface at this temperature. The researchers used a scanning tunneling microscope to observe the dispersion of the single atoms on the copper support and to study how molecular hydrogen can detach at individual palladium sites and drop onto the copper layer. Mass spectrometry revealed that the new alloy had catalyzed the hydrogenation of acetylene and styrene with more than 95% selectivity.

Maria Flytzani-Stephanopoulos, professor in energy sustainability, Georgios Kyriakou, assistant professor of chemistry, and Matthew Boucher, a Ph.D. student, have led the single-atom alloy testing. The team is looking at ways to use the single-atom alloy catalysts as affordable substitutes in hydrogenation processes to produce green foods, pharmaceuticals and agricultural chemicals.