Eighteen major research and industrial partners have teamed up in a European Union (EU) Fast Track project to develop high-efficiency thin-film silicon solar modules using nanotechnology.

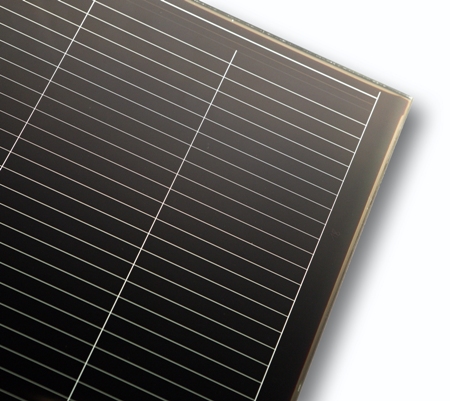

Thin-film silicon solar modules can be produced much more economically than conventional solar cells. In the case of thin-film modules, the silicon is applied to the substrate in a layer about one micrometre thick and does not need to be carefully cut out from expensive wafers. (Source: Forschungszentrum Jülich)

Thin-film silicon solar modules can be produced much more economically than conventional solar cells. In the case of thin-film modules, the silicon is applied to the substrate in a layer about one micrometre thick and does not need to be carefully cut out from expensive wafers. (Source: Forschungszentrum Jülich)

The objective of the project is to fabricate a commercial prototype of next-generation thin-film solar modules with 12% efficiency in the next three years. The partners include Forschungszentrum Jülich; Ècole Polytechnique Fédérale de Lausanne; Fyzikální ústav AV ČR; Univerza v Ljubljani; CVD Technologies; Universiteit Utrecht; Centre national de la recherche scientifique; Uniresearch; Stichting Energieonderzoek Centrum Nederland; Agenzia nazionale per le nuove tecnologie, l'energia e lo sviluppo economico sostenibile; Technische Universität Dresden; Oerlikon Solar; Technische Universiteit Delft; Malibu; Forschungs- und Applikationslabor Plasmatechnik; Euroglas; SolarExcel; and SINGULUS Stangl Solar.

Forschungszentrum Jülich is the coordinator of the project, which has received a fund worth € 9.3 million from the EU. The project, launched on March 1, 2012, is scheduled to run until February 28, 2015. The inaugural meeting of the project was conducted in Jülich from March 28 to 29, 2012.

The current efficiency of commercial thin-film solar modules is 10%, which is comparatively lower than the efficiency of conventional solar cells. However, one of the advantages of the thin-film solar modules is their lower production cost as they can be produced by applying silicon to a 1-µm-thick substrate layer and need not to be selectively cut out from high-cost wafers.

Tandem solar cells, comprising two layers atop each other, are particularly efficient as these layers can absorb various fractions of sunlight. Each of these layers is partitioned into multiple sub-layers, which interact with each other in a complicated and unpredictable manner. Hence, current thin-film solar cells are being produced using proven combinations of substrates and components.

In the Fast Track project, research and industry partners with their vast experience will optimize and integrate different techniques and components in order to fabricate a new-generation of thin-film silicon solar modules with 12% efficiency at a cost below € 0.5 per watt nominal power. For this purpose, the partners will test several optical functional layers and nanomaterials and upgrade the whole process chain. They will try to manipulate the electronic and optical properties through the utilization of an innovative multiphase material called nanocrystalline silicon dioxide. The material’s solid structure offers more options than pure silicon.

Although nanostructures can optimize light trapping, the structure of the perfect light-scattering layer has not been predicted yet. Forschungszentrum Jülich’s Dr. Aad Gordijn, who is the Project Coordinator, informed that the partners will study the superimpositions of various structures based on pyramids or craters to design an optimized morphology.