Umeco has collaboratively developed flax reinforced composites and recycled composites. The parts for the prototype racing car, the Lola-Drayson B12/69EV, which is an all-electric vehicle have been manufactured using these products. The racing car is set for participation in the FIA Formula E World Championship Series.

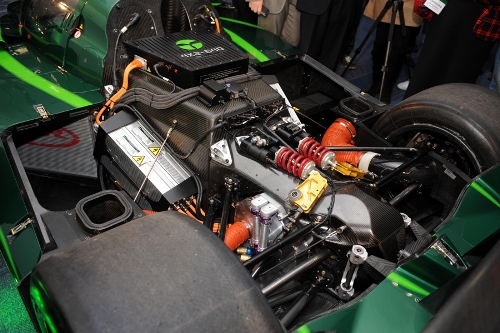

Use of composites under the engine cover of the Lola-Drayson B12/69EV. © Lola Cars International Ltd.

Use of composites under the engine cover of the Lola-Drayson B12/69EV. © Lola Cars International Ltd.

The Lola-Drayson racing car is a joint development between Drayson Racing Technologies and the Lola Group. The car racing championship is to be held in 2013.

Umeco partnered with ELG Carbon Fibre and WMG to study and develop recycled composite materials. ELG reclaimed carbon fibres from MTM49 epoxy prepreg that was out of life. Umeco’s toughened epoxy resin MTM49 was then re-impregnated into the material. The companies performed tests on the material to find out its impact and mechanical properties. These properties were compared with original virgin prepregs. The tests revealed that the stiffness of the fibres was comparable to the original virgin prepregs and that the loss of strength was minimal.

Umeco has collaborated with Composites Evolution and WMG to conduct research and develop flax-reinforced composites. The woven flax material was provided by Composites Evolution. Umeco’s MTM28 and MTM49 epoxy resins were impregnated in the material. The Warwick Innovative Manufacturing Research Centre and the Engineering and Physical Sciences Research Council supported the WMG at the University of Warwick. Flax fibres possess good insulating and vibration damping qualities. While they have mechanical properties comparable to that of glass fibres, they have a lesser environmental impact.

Lola has been involved in the project and has specified the criteria necessary for the parts in the 850 hp Lola-Drayson B12/69EV car. A range of parts have been manufactured using MTM49/Biotex Flax and MTM28/Biotex Flax material. The racing car features electrical regenerative damping, composite battery power, inductive charging and moveable aerodynamics, making it an innovative sustainable ‘green’ technology project.