Researchers from the University of Wisconsin-Milwaukee (UWM) have developed nitrogen-enriched iron-carbon nanorods, which can be used as a low-cost alternative to platinum catalysts used in microbial fuel cells (MFCs).

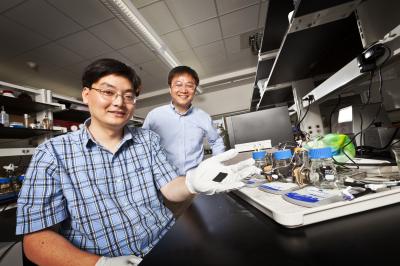

Zhen (Jason) He, assistant professor of civil engineering (left), and Junhong Chen, professor of mechanical engineering, display a strip of carbon that contains the novel nanorod catalyst material they developed for microbial fuel cells. (credit: Troye Fox)

Zhen (Jason) He, assistant professor of civil engineering (left), and Junhong Chen, professor of mechanical engineering, display a strip of carbon that contains the novel nanorod catalyst material they developed for microbial fuel cells. (credit: Troye Fox)

With equivalent efficiency and 5% of the cost of a platinum catalyst, the novel material paves the way to develop more economical storage and energy conversion devices. The nitrogen-enriched iron-carbon nanorods, developed by UWM Professor Junhong Chen, show promise to substitute the platinum catalyst in microbial electrolysis cells (MECs) that produce hydrogen.

Chen together with Assistant Professor Zhen (Jason) He is carrying out tests on the nanorods. The researchers discovered that the nanorod catalyst demonstrated a performance better than a graphene-based catalyst. Moreover, the nanorod catalyst consistently outperformed two other potential substitutes for platinum over a period of six months.

According to Chen, the nanorods have demonstrated scalability and stability. However, more research is required to find the method of mass-production of the novel material and to identify the cause for its superior performance. The study results have been reported in the Advanced Materials journal.

The nanorod catalyst consists of nitrogen affixed to the carbon rod surface and an iron carbide core. It is a known fact that a carbon catalyst’s efficiency can be improved by nitrogen. Iron carbide, which also demonstrates better catalytic functionalities, interplays with the carbon on the surface of the rod, thus communicating with the core. Moreover, the material’s novel structure is favorable for electron transport, which is crucial for oxygen reduction reaction.

The nitrogen-enriched iron-carbon nanorod catalyst outperformed graphene-based catalyst material in MECs; however, its efficiency is lower than that of the platinum catalyst. He commented that this result demonstrates that the nanorods hold potential for more different applications than graphene and provides evidence to the difference in performance of the nanorods in MECs.