Nov 21 2012

Alstom today announced the launch of its “LP75” very long Last Stage Blade* (LSB) for nuclear steam turbines at the Nuclear New Build Summit in Shanghai.

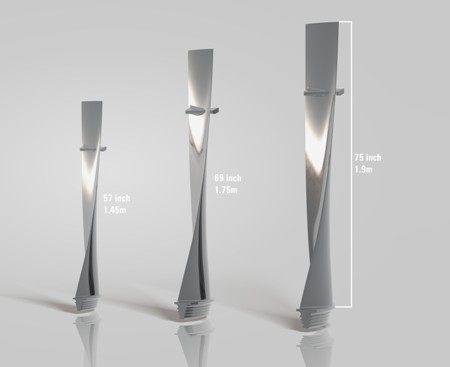

The Arabelle Last Stage Blade Product Range

The Arabelle Last Stage Blade Product Range

This 75” new blade is the longest in the world and its exhaust area** of 58m2 is the largest compared to any other product on the market. Designed for use in the low pressure section of Alstom’s Arabelle nuclear steam turbine, the LP75 builds incrementally on Alstom's existing LP69 turbine blade to improve performance and achieve the best possible efficiency from any nuclear steam turbine today.

The LP75 provides a reduction of one-fifth in exhaust losses compared with the existing LP69. This means that energy waste is minimised while electrical output can be maximised: Depending upon project specific conditions, typically an output gain of 10 MW is expected, enough to provide the yearly electricity consumption of 60,000 Chinese households.

In particular the upgraded LP75 blade can provide more output in cold and very cold cooling conditions from all reactor models. It is thus well suited for climates such as the UK, Scandinavia, or at coastal locations in temperate to very cold areas.

“Our 69” LSB in operation at Oskarshamn, Sweden is already the longest blade in commercial operation in the world. The LP75 builds on Alstom's existing expertise and will give our nuclear power customers increased electrical output to enhance their plant performance,” said Patrick Fragman, Senior Vice President of Nuclear.

With this new blade, the Arabelle LSB line now offers three sizes LP57, LP69 and LP75 and greater flexibility in plant design. Featuring the same welded rotor technology and lightweight LSB design of those earlier models, the LP75 also uses similar manufacturing processes and shares many parts, thanks to a progressive product evolution. This helps to mitigate risks of equipment failure as well as costly delays.

The Arabelle steam turbine currently powers six nuclear units and is under various stages of construction in another 18 units in four countries.

* Last Stage Blades are part of the low pressure module in a steam turbine generator which converts heat energy from steam into electricity in a nuclear power plant. Longer blades reduce exhaust losses, increase efficiency of a steam turbine and allow to further optimise backpressure – all of which contribute to greater power output of the nuclear power plant.

** Exhaust area is measured at the blade exit.