Jan 10 2013

Sandia National Laboratories Truman Fellow Anne Ruffing has engineered two strains of cyanobacteria to produce free fatty acids, a precursor to liquid fuels, but she has also found that the process cuts the bacteria’s production potential.

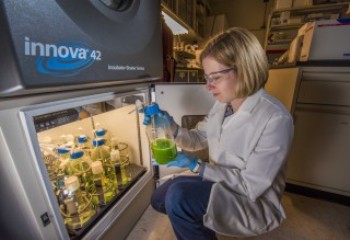

Truman Fellow Anne Ruffing looks at a flask of cyanobacteria with precipitated fatty acid floating on top. She has engineered two strains of cyanobacteria to produce free fatty acids, a precursor to fuels, as she studies the direct conversion of carbon dioxide into biofuels by photosynthetic organisms.

Truman Fellow Anne Ruffing looks at a flask of cyanobacteria with precipitated fatty acid floating on top. She has engineered two strains of cyanobacteria to produce free fatty acids, a precursor to fuels, as she studies the direct conversion of carbon dioxide into biofuels by photosynthetic organisms.

Micro-algal fuels might be one way to reduce the nation’s dependence on foreign energy. Such fuels would be renewable since they are powered by sunlight. They also could reduce carbon dioxide emissions since they use photosynthesis, and they could create jobs in a new industry. President Barack Obama, speaking in February at the University of Miami, advocated for investments in algae fuel development, saying they could replace up to 17 percent of the oil the United States now imports for transportation.

“Even if algae are not the end-term solution, I think they can contribute to getting us there,” Ruffing said. “Regardless of however you look at fossil fuels, they’re eventually going to run out. We have to start looking to the future now and doing research that we’ll need when the time comes.”

She has been studying the direct conversion of carbon dioxide into biofuels by photosynthetic organisms under a three-year Truman Fellowship that ends in January. She presented her project at a poster session in August and published her work on one strain, “Physiological Effects of Free Fatty Acid Production in Genetically Engineered Synechococcus elongatus PCC 7942,” as the cover article in the September 2012 issue of Biotechnology and Bioengineering.

Ruffing considers her studies as proof-of-concept work that demonstrates engineering cyanobacteria for free fatty acid (FFA) production and excretion. She wants to identify the best hydrocarbon targets for fuel production and the best model strain for genetic engineering, as well as gene targets to improve FFA production.

She is using cyanobacteria — blue-green algae — because they are easier to genetically manipulate than eukaryotic algae, the natural “oil”-producing photosynthetic microorganisms more commonly used for algal biofuels, and because cyanobacteria can be engineered to create a variety of target fuels. Genetically engineered cyanobacteria excrete FFA and allow fuel to be collected without harvesting the cyanobacteria. This lowers the requirement for nitrogen and phosphate and reduces costs.

But current yields from engineered strains are too low for large-scale production.

Ruffing favors cyanobacteria because fuel from engineered cyanobacteria is excreted outside the cell, in contrast to eukaryotic algae, in which fuel production occurs inside the cell.

In general, this is how the process works: Eukaryotic algae grow in a pond to the density needed, then producers must get rid of the water, collect the cells and break them open to get the fuel precursor inside. This precursor is isolated and purified, then chemically converted into biodiesel. Cyanobacteria excrete the fuel precursor outside the cell, so a separation process can remove the product without killing the cells. That eliminates the need to grow a new batch of algae each time, saving on nitrogen and phosphate.

While other research efforts have focused on metabolic engineering strategies to boost production, Ruffing wants to identify what physiological effects limit cell growth and FFA synthesis.

“You can’t really hope to continue to engineer it to produce more of the fatty acids until you address these unforeseen effects,” she said. “As much as you want to do the applied side of things, creating the strain, you can’t get away from the fundamental biology that’s necessary in order to do that.”

Much of our fundamental understanding of photosynthesis comes from cyanobacteria, but it’s only been in the past decade or so, with advances in gene manipulation and recombinant DNA technology, that they’ve been considered for fuel production, Ruffing said.

The strains she engineered for FFA production show reduced photosynthetic yields, degradation of chlorophyll-a and changes in light-harvesting pigments, Ruffing said. She saw some cell death and lower growth rates overall, and suspects the toxicity of unsaturated FFA and changes in membrane composition are responsible.

Now she’s looking at what genes are changing when cyanobacteria produce fatty acids. She’s creating mutants by knocking out certain genes or introducing or overexpressing genes to see how that affects the cell and fatty acid production.

“So I’m engineering the cell, then I’m trying to learn from the cell how to work with the cell to produce the fuel instead of trying to force it to produce something it doesn’t want to produce,” she said.

She’s producing FFA from Synechococcus elongatus PCC 7942 and Synechococcus sp. PCC 7002, chosen as so-called model organisms that have been studied for several decades and for which tools exist to manipulate their genes. She also is working with the two strains and a third, Synechocystis sp. PCC 6803, for biofuel toxicity screening.

Ruffing hopes to continue working on strain development after the fellowship ends.

“It is possible that there’s a natural strain out there that could be a better option, so this is still pretty early research,” she said. “There’s a lot of exploration to do.”

Sandia National Laboratories is a multiprogram laboratory operated and managed by Sandia Corporation, a wholly owned subsidiary of Lockheed Martin Corporation, for the U.S. Department of Energy’s National Nuclear Security Administration. With main facilities in Albuquerque, N.M., and Livermore, Calif., Sandia has major R&D responsibilities in national security, energy and environmental technologies, and economic competitiveness.