Alcoa and The Saudi Arabian Mining Company (Ma’aden) today announced completion of a first-of-its-kind engineered wetlands wastewater management system in Saudi Arabia at the Ma’aden-Alcoa joint venture project site.

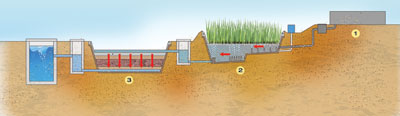

Alcoa’s wetlands system comprises three steps including (1) an anaerobic treatment tank which breaks down and separates organic material in the water; (2) a passive engineered wetland that utilizes vegetation for further treatment of organics and removal of nitrogen and metals; and (3) a cell housing bauxite-based technology that disinfects and polishes the water. The result is water treated to the same or better quality as that of a conventional system.

Alcoa’s wetlands system comprises three steps including (1) an anaerobic treatment tank which breaks down and separates organic material in the water; (2) a passive engineered wetland that utilizes vegetation for further treatment of organics and removal of nitrogen and metals; and (3) a cell housing bauxite-based technology that disinfects and polishes the water. The result is water treated to the same or better quality as that of a conventional system.

The newly constructed system will reduce water demand by nearly two million US gallons (7.5 million litres) per day and save more than US$7million (SAR 26 million) annually that would otherwise be used to purchase fresh water.

The Alcoa-designed and engineered technology – known as a Natural Engineered Wastewater Treatment system – collects sanitary and industrial wastewater and then cleans and disinfects the water without the use of chemicals or the creation of water discharge and odors associated with conventional tank systems. The water will then be reused in the manufacturing process and for irrigation at the Ma’aden-Alcoa aluminum complex at Ras Al Khair. The complex includes a refinery, smelter and rolling mill.

“Sustainable development is a core value for Ma’aden,” said Abdulaziz A. Al Harbi, Ma’aden Aluminium’s president. “It is also a critical component of our operating excellence that will enable Ma’aden Aluminium to become the world's lowest-cost producer of primary aluminum, alumina and aluminum products, with access to growing markets in the Middle East and beyond.”

“This innovative waste management system demonstrates the value of combining Ma’aden’s local knowledge and expertise with the technological depth and sustainability leadership that Alcoa brings to the Ma’aden-Alcoa joint venture,” said Ray Kilmer, Alcoa’s Executive Vice President and Chief Technology Officer. “Together with Ma’aden, we are bringing to life this oasis in the desert which will safely treat and conserve water in a way that is good for the environment and the bottom line.”

This sustainable technology, demonstrated via full-scale deployment at the Alcoa Technical Center near Pittsburgh, Pennsylvania, is now being considered for other wastewater treatment applications throughout Saudi Arabia.

Alcoa technical experts developed the system to mimic the physical, chemical and biological processes of natural wetlands. In addition to saving water and money, the innovative design was constructed six months faster than a conventional tank-based system and eliminated an estimated 1,000 metric tons of steel for piping and tanks. The project is expected to be fully operational by the end of July this year.

Alcoa’s wetlands system comprises three steps including (1) an anaerobic treatment tank which breaks down and separates organic material in the water; (2) a passive engineered wetland that utilizes vegetation for further treatment of organics and removal of nitrogen and metals; and (3) a cell housing bauxite-based technology that disinfects and polishes the water. The result is water treated to the same or better quality as that of a conventional system.

For more information on the Ma’aden-Alcoa joint venture project visit: http://www.alcoa.com/saudi_arabia/.