Jun 11 2013

The only truly practical biofuels will be those made from abundant feedstocks like switchgrass, wheat straw, and other woody plants, whose cell walls consist of lignocellulose. After pretreatment to remove or reduce the lignin, the sugary remains of cellulose and hemicellulose are fermented by microorganisms to yield the biofuel.

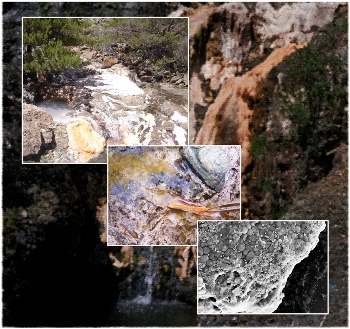

Eroding serpentine rock in The Cedars creates highly alkaline springs. Lignin in plant matter that falls into the springs is attacked by the alkalinity, while alkili-tolerant strains of Cellulomonas and other microorganisms break down the cellulose and process the sugars. (The Cedars photos by Michael Cohen and Nathan Rank, inset micrograph of FA1 Cellulomonas on switchgrass by Nina Kamennaya, Lawrence Berkeley National Laboratory)

Eroding serpentine rock in The Cedars creates highly alkaline springs. Lignin in plant matter that falls into the springs is attacked by the alkalinity, while alkili-tolerant strains of Cellulomonas and other microorganisms break down the cellulose and process the sugars. (The Cedars photos by Michael Cohen and Nathan Rank, inset micrograph of FA1 Cellulomonas on switchgrass by Nina Kamennaya, Lawrence Berkeley National Laboratory)

“Each additional step in the process adds to the cost,” says Michael Cohen, a professor of biology at Sonoma State University who has discovered bacteria that could, with a little help from bioengineers at the U.S. Department of Energy’s Lawrence Berkeley National Laboratory (Berkeley Lab), increase the efficiency and reduce the cost of biofuel processing. “The species of bacteria we’re testing may be able to combine two important steps into one.”

Cohen found the unique strain of bacteria, which can tolerate high alkalinity and degrade cellulose at the same time, in a strange and isolated part of California called The Cedars, located inland from Timber Cove in the state’s Outer Coast Range. The site’s deep canyons and rocky serpentine barrens, all but invisible from the area’s few public roads, create a biological island that is home to living things rarely seen elsewhere.

Although industrial pretreatments for reducing lignin range from steam explosions to acid baths (low pH), Cohen knew that some of the most effective technologies soak the feedstock not in acid but its opposite, highly alkaline liquid (high pH), which breaks up the woody matrix to release the digestible hydrocarbons, the sugars. Only then are the bugs – microbes – added to do the fermenting.

What drew Cohen to The Cedars were its spectacular travertine springs, formed of calcium carbonate from eroding serpentine rock. On the logarithmic pH scale the spring water reached a remarkable pH 11.9, compared to pure water’s pH 7. With help from botanist Roger Raiche, who has led the effort to preserve The Cedars as an ecological preserve, Cohen took samples of decaying plant material and the diverse community of microorganisms in the springs.

“It was a case where nature was mimicking an industrial process, soaking the woody material in a high pH solution and breaking down the cellulose with microorganisms,” says Cohen. The task was to identify and isolate which bugs were the cellulose degraders.

Out of the woods and onto the lab bench

As a participant in DOE’s Visiting Faculty Program at Berkeley Lab, which supports research by outside faculty through collaborations with Lab scientists, Cohen worked with expert microbiologists Tamas Torok, Hoi-Ying Holman, and other members of the Earth Sciences Division.

Torok searches for extremophiles, bugs that thrive in harsh environments such as intense heat or radiation, in places like the Chernobyl Exclusion Zone, the steppes of Central Asia, and the mud pots of the Kamchatka Peninsula. Holman, the director of the Berkeley Synchrotron Infrared Structural Biology (BSISB) program at the Lab’s Advanced Light Source, studies real-time chemical processes in living cells on the microscopic scale.

On samples of ground-up switchgrass Cohen cultured communities of microorganisms, both bacteria and fungi, from decaying plants in alkaline spring water from The Cedars. Once the cultures were established, they were maintained in water that imitated the chemical composition of the original spring water. Using synchrotron infrared spectromicroscopy at the BSISB, Cohen and his colleagues were able to isolate eight or nine active cellulose degraders. One stood out.

“It was a strain of Cellulomonas bacteria, the only strain we extracted under oxygen-depleted conditions,” says Cohen. The FA1 strain was either aerobic (thriving in air) or anaerobic (living without air) depending on its environment. It could survive without oxygen, but, unlike most anaerobes, oxygen would not poison it.

FA1’s response to highly alkaline conditions was similar. “Cellulomonas FA1 is not an extremophile,” Cohen says. “It doesn’t love high pH, and in fact it would prefer a more neutral environment – but it’s highly alkali tolerant.”

Promising as it is, Cellulomonas FA1 leaves much room for improvement. “Unlike yeast, bacteria have many fermentation pathways, so when it comes to making biofuel contenders like ethanol, FA1 probably can’t make much,” Cohen says. Of the Cellulomonas species that can excrete ethanol, most would die if the ethanol concentration exceeded one percent. Only a few can tolerate up to 12 percent.

Turning an organism with remarkable properties – the ability to withstand extreme alkaline conditions and a complete lack of oxygen while degrading cellulosic biomass – into an efficient producer of biofuel is a challenge for the metabolic engineer.

In fact, it’s a Billion-Ton Challenge, described in DOE’s strategic analyses of U.S. agriculture and forestry resources for providing a billion tons of sustainable biomass annually, with the aim of reducing the country’s petroleum consumption by 30 percent. With the biomass available, the challenge becomes one of industrial technique.

“That challenge is beyond our capacities at Sonoma State University, but it could be done at Berkeley Lab – I’m already at work on the proposal,” says Cohen. “Cellulomonas FA1 is the best starter organism I could think of.”