Dec 12 2013

Sapphire Energy, Inc., one of the world leaders in algae-based Green Crude oil production, and Phillips 66, an integrated energy manufacturing and logistics company, announced a strategic joint development agreement aimed at taking production of algae crude oil a significant step toward commercialization.

The companies will work together to collect and analyze data from co-processing of algae and conventional crude oil into fuels. The goal is to complete fuel certifications to ready Sapphire Energy's renewable crude oil, called Green Crude, for wide-scale oil refining.

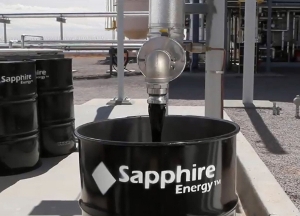

Sapphire Energy is producing Green Crude oil from algae year-round at the Green Crude Farm. (PRNewsFoto/Sapphire Energy, Inc.)

Sapphire Energy is producing Green Crude oil from algae year-round at the Green Crude Farm. (PRNewsFoto/Sapphire Energy, Inc.)

Under the agreement the companies will expand Sapphire Energy's current testing programs to further validate that Green Crude can be refined in traditional refineries and meet all of the Environmental Protection Agency's (EPA) certification requirements under the Clean Air Act. This includes determining the optimal operating conditions for processing algae crude oil into American Society for Testing and Materials (ASTM)-certified diesel, gasoline and jet fuel. Once the study is finished, the companies will work together to complete the EPA certification process to register a new fuel product entering the market.

"In under a year, Sapphire Energy has entered into contracts with two major companies in the oil and gas industry, showing that there is increasing momentum for algae fuel as a viable crude oil alternative, and significant interest by refiners to have new and better options to meet the California Low Carbon Fuel Standard (LCFS) and the federal Renewable Fuel Standard (RFS)," said Cynthia 'CJ' Warner, CEO and chairman of Sapphire Energy. "We're looking forward to building a strong relationship with Phillips 66, an established leader in research and development for next generation fuels, who understands the opportunity our Green Crude oil holds as a feasible and sustainable crude oil choice for refiners."

"Phillips 66 is committed to providing energy and improving lives. We are continually on the lookout for promising technology advances in energy manufacturing and logistics," said Merl Lindstrom, vice president of Technology for Phillips 66. "We believe this joint development project with Sapphire Energy could produce a refinery-ready, sustainable product for Phillips 66, creating yet another exciting opportunity in this rapidly changing energy landscape."

Combining Phillips 66's experience in algae research and technical expertise in hydroprocessing and fuels upgrading with Sapphire Energy's algae cultivation knowledge could yield promising results. This new relationship with Sapphire Energy complements other Phillips 66 renewable fuels collaborations in academia and other sectors to convert a wide array of sustainable feedstocks to transportation fuels. The company's biofuels platform is one piece of a technology strategy that also includes research and development of fuel cells and solar cells.

Sapphire Energy is now producing crude oil daily from algae biomass cultivated and harvested at the company's Green Crude Farm, located in Columbus, N.M. The farm is the world's first algae-to-energy facility that demonstrates the entire value chain of algae-based crude oil production, from cultivation, to harvest, to the conversion of biomass into ready-to-refine crude oil. In initial testing by Sapphire Energy, Green Crude oil was upgraded into on-spec ASTM 975 diesel fuel, proving its compatibility with the existing network of pipelines, refineries and transport systems. The company expects to be at commercial demonstration scale in 2015, commercial scale in 2018, and is eventually projected to produce 1 billion gallons per year by 2025.

About Sapphire Energy

San Diego-based Sapphire Energy is pioneering an entirely new industry – Green Crude production – with the potential to profoundly change America's energy and petrochemical landscape for the better. Sapphire's products and processes in this category differ significantly from other forms of biofuel because they are made solely from photosynthetic microorganisms (algae and cyanobacteria), using sunlight and CO2 as their feedstock; are not dependent on food crops or valuable farmland; do not use potable water; do not result in biodiesel or ethanol; enhance and replace petroleum-based products; are compatible with existing infrastructure; and are low carbon, renewable and scalable. Sapphire has an R&D facility in Las Cruces, New Mexico, and is currently operating the first Integrated Algal BioRefinery in Columbus, New Mexico, continuously since May 1, 2012.