SELFRAG has developed a revolutionary process for commercial recycling of incinerator slag using high voltage electrodynamic fragmentation.

The first commercial recycling system for incinerator slag is to be installed in Switzerland for SAIDEF in Posieux, Canton Fribourg. It will be ready for operation in the early part of 2016.

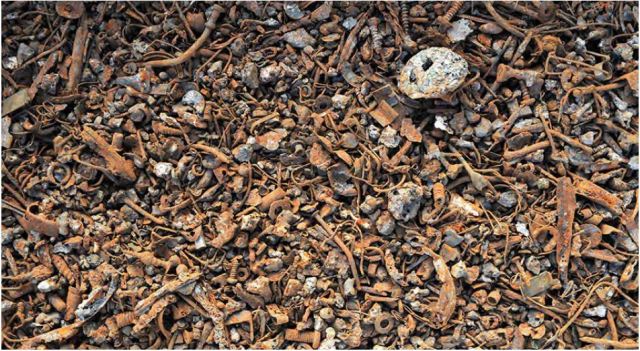

Ferrous metal after processing and sorting

Ferrous metal after processing and sorting

Slag, or bottom ash, can contain high levels of both ferrous and non-ferrous metals. This could be a useful source of these valuable materials. The proportion of metals in slag could be 50 to 100% higher than in natural mineral deposits such as copper mines

During incineration, the high temperature involved in the process causes an agglomeration of the various fractions. This agglomeration has made it challenging to recover the valuable fraction in an economical manner.

The innovative process developed by SELFRAG involves a high voltage fragmentation process for separating the recyclable fractions. The high voltage pulse generators produce electrical discharges that can be compared to the discharges caused by lightning.

The slag fractions are effectively separated by the powerful shockwaves generated by the artificial lightning discharges. This preferential fragmentation method has a selective nature that improves the quality and quantity of the recycled materials.

Untreated Slag

SAIDEF, which has incinerator operations in Posieux, aims to reduce its landfill requirements by 30% by utilizing the SELFRAG system, and also double its ferrous and non-ferrous metals recovery.

The CEO of SAIDEF, Albert Bachmann, reported on the VBSA symposium:

“Extensive tests convinced us of this new technology. We can double our recovery, especially for non-ferrous metals. The recovered metals are cleaner and will generate a higher sales price.

"Additionally, about 5 to 10% of the total slag volume is completely cleaned, fulfilling stringent Swiss regulations on inert fractions and can be potentially used as aggregates in road construction, which opens up another income source.

"The metal recycling, together with the decontamination of the remaining material, will reduce the waste to be landfilled by 20-30%, leading to a cost saving of CHF 50 per tonne. There is an additional benefit through the reduction of fossil CO2 emission from the waste incineration process, a mandatory requirement in Switzerland from 2020.”

Frédéric von der Weid, CEO of SELFRAG, stated:

“SELFRAG is a recognized pioneer in the field of electrodynamic fragmentation. Our vision is to establish an economical recycling method for the respectful use of the world’s resources. Thanks to our new slag treatment system the metals from the waste in Fribourg will be re-used instead of being landfilled. We hope that this project is a paradigm shift and will convince other cities too.”

SELFRAG and Frei Fördertechnik are to collaborate in the installation of the 3t/hour system in Posieux. Collin Frei, CEO of Frei Fördertechnik, commented:

“The partnership between SELFRAG and Frei Fördertechnik allows us to offer a combination of state-of-the-art technology with proven systems engineering capabilities within the incinerator and landfill industries.

"The partnership enables optimized processing, sorting and conveying of bottom ash, delivering immediate financial benefits and setting a new standard for environmentally friendly treatment of bottom ash.”