Feb 24 2015

FCO Power Inc. today announced the further development of its next-generation solid oxide fuel cell (SOFC) stack for residential fuel cell systems in existing apartments. Use of the stack makes it realistic to install fuel cells in existing apartments, which account for approximately 40 percent of housing in Japan, from 2020.

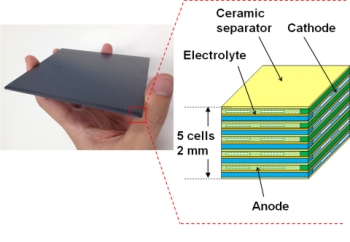

Printed Fuel Cell(TM) appearance and conceptual diagram (Graphic: Business Wire)

Printed Fuel Cell(TM) appearance and conceptual diagram (Graphic: Business Wire)

Printed Fuel CellTM features

The Printed Fuel CellTM is a SOFC in which all single cell layers, including separators (anode, electrolyte, cathode, and ceramic separator) are laminated repeatedly before sintering and subsequently simultaneously sintered only once as a stack.

The Printed Fuel CellTM does not require a cell support because it does not need to maintain mechanical strength as single cell unit. As a result, the total thickness of a single cell and separator is just 0.4 mm, which is approximately one tenth the thickness of conventional technology. Because it is so thin, The Printed Fuel CellTM achieves 5 kW/L, which is the highest level in the world.

Additionally, the Printed Fuel CellTM has a simple, thin laminated structure that requires a limited amount of material and parts, making it suitable for low-cost, automated mass production. As a result, FCO Power expects to be able to price the Printed Fuel CellTM at a level that is well below NEDO’s target stack price of JPY50,000 /kW for 2020 to 2030.

Features of next-generation SOFC stack for residential use

The stack under development for residential 700W systems leverages the Printed Fuel CellTM features and is only 3 cm thick. The stack comprises a number of 70W stacks.

This all-ceramic SOFC stack has a unique stack cooling structure, which allows the use of thin layers and simultaneously homogenizes the overall stack temperature distribution. As a result, the hot module volume, including heat insulation materials, is less than one quarter of that of existing products.

SOFC system with next-generation SOFC stack

Use of this next-generation stack makes the hot module thin and compact. This means that it is realistic to develop SOFC systems for existing apartments, such as wall-mounted and porch installation. By leveraging high volumetric power density and low-cost stack technology, FCO Power and its alliance partners aim to commercialize the SOFC system in 2020, the year of the Tokyo Olympics.

FCO Power aims to contribute further energy saving and greenhouse gas reduction in the residential sector by expanding the fuel cell target market to existing apartments in addition to current detached houses and newly-built apartments.

This next-generation SOFC stack will be exhibited at the 11th International Hydrogen & Fuel Cell Expo from February 25 to February 27, 2015, at Tokyo Big Sight. Part of this development was conducted with the support of a New Energy and Industrial Technology Development Organization grant.

SOFC background

Among the several types of fuel cell available, SOFCs are expected to become especially widely used because of their higher power generation efficiency and ability to operate with a diverse variety of gases. Although SOFC systems for residential use have already been commercialized, the current target market is limited to detached houses and some newly-built apartments. Existing apartments, which account for approximately 40 percent of housing in Japan, are out of scope.

The main reason is that the SOFC stack is bulky and high cost. However, FCO Power is developing a next-generation stack, which is only 3 cm thick for 700W residential system by leveraging the Printed Fuel CellTM, a unique high volumetric power density and low-cost SOFC.