Aug 18 2015

By combining information about power plant operation with real-time air quality predictions, researchers have created a new capability to minimize the human health effects of air pollution resulting from electric power generating facilities.

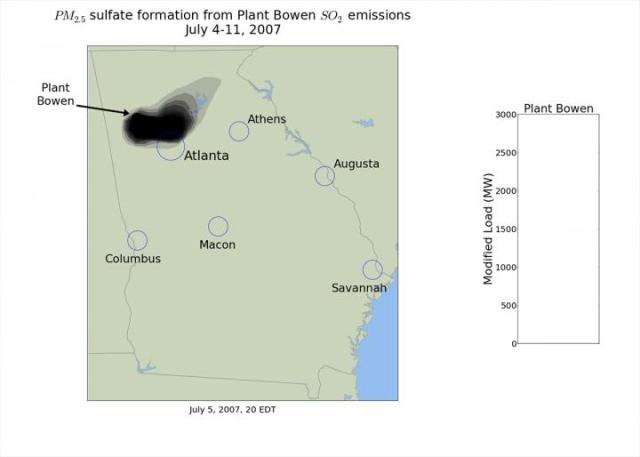

A still frame from the air quality prediction model shows the expected location of impacts from the emissions of an electric generation facility in Georgia, based on data from 2007. Limiting the output of the plant when the impacts are occurring in major population centers could reduce health effects of the emissions. Credit:Georgia Tech

A still frame from the air quality prediction model shows the expected location of impacts from the emissions of an electric generation facility in Georgia, based on data from 2007. Limiting the output of the plant when the impacts are occurring in major population centers could reduce health effects of the emissions. Credit:Georgia Tech

The Air Pollutant Optimization Model, described in the journal Proceedings of the National Academy of Sciences, provides a new approach for reducing the health effects of ozone and fine particulate pollution. By helping to minimize both health impacts and generating costs, the hybrid model may provide a new tool for utility companies seeking to meet air quality standards, complementing traditional capital-intensive emission controls.

In a test case based on data for the state of Georgia for selected months from 2004 to 2011, the new model suggests that health impacts could have been reduced by $176 million, while increasing generating costs by $84 million - a net savings of approximately $92 million in health costs. For power systems elsewhere, costs and savings would vary by the types of fuel used, the locations of generating facilities and the amount of flexibility available in regional power systems.

The test case evaluated sulfate emissions in Georgia prior to installation of flue gas desulfurization units, which have since reduced emission of that pollutant by as much as 97 percent. Sulfates are a major source of fine particulate matter.

"We looked at what would be the least expensive way of running these power plants if you take into account both the generating costs and the health impact costs," said Valerie Thomas, one of the paper's senior authors and a professor in the School of Industrial and Systems Engineering and School of Public Policy at the Georgia Institute of Technology. "You would still be operating plants that emit pollutants, of course, but you would reduce operations at the ones having the greatest impact and increase the use of facilities that have less impact or are in other areas."

The new approach depends on the use of "reduced form" air quality predictions. Comprehensive air quality models typically take days of computer time to calculate concentrations of pollution for one emissions scenario, but the new format uses only the "sensitivities" derived from the full model to accurately produce predictions in less than a second. This capability allows utility companies, for the first time, to test many possible scenarios in evaluating how air quality would change with different combinations of generating plant operations.

For instance, when wind conditions carry emissions from one generating facility toward a major population center, that plant could be throttled back and power from a facility affecting fewer people used in place of it.

"For the first time, we have integrated the capability for rapidly predicting air quality into the electricity system operation model," said Athanasios Nenes, a professor in Georgia Tech's School of Earth and Atmospheric Sciences and School of Chemical & Biomolecular Engineering. "We can now run thousands of scenarios very quickly, as the winds and other conditions change hourly, to find the most economical way to generate electricity that minimizes population exposure to pollution."

Georgia Tech environmental researchers have been developing and refining air quality models for decades, and now operate models to help regulatory agencies predict when air quality could reach levels of concern. At the same time, other Georgia Tech researchers have studied optimization of power generation to produce power at the lowest cost.

"Putting these technologies together has given us a capability we've never had before," said Armistead Russell, a professor in Georgia Tech's School of Civil and Environmental Engineering. "Tradeoffs are always made, but right now those decisions have to be made without the necessary knowledge."

In Georgia, electricity generating facilities use a variety of fuels, including nuclear, coal, natural gas and biomass. The generating facilities range in size, and have differing capabilities to be powered up and down in time scales consistent with changes in the weather, Thomas said.

"We are accustomed to modeling the aspects of how these plants work together to meet demands, which varies on different days of the week and at different seasons of the year," she explained. "None of the plants can be flipped on or off like a light bulb, but the utility companies can adjust up and down the amount of power they are producing."

Certain generating facilities cost more to operate, and when they are used to substitute for power generated by less expensive facilities, that raises the overall cost. However, the model shows that these higher generating costs can be more than offset by reductions in human health costs.

"This is really all about 'smart generation,'" said Nenes. "If there's a way to meet the standards by controlling who emits what and at what time, that may change the amount of investment you'd need to make in new emission control equipment. Hour-by-hour, we'll be able to determine what makes the most sense in terms of both cost to produce electricity and its impacts."

While the hybrid Air Pollutant Optimization Model tracks many forms of pollutants, those regulated by the U.S. Environmental Protection Agency are fine particulates and ozone. Fine particulates can affect cardiovascular and respiratory health, while ozone at high concentrations can trigger asthma attacks in susceptible persons.

Power plants currently account for about a third of pollution, but as a next step, the researchers hope to include emissions from mobile sources such as automobiles in their model. The researchers are also evaluating use of their model in countries such as China and India that have greater pollution concerns.