Jan 29 2016

Stephen Foley, an associate professor in the Department of Chemistry at the University of Saskatchewan (U of S), and his team appear to possess the Midas touch when it comes to research on the extraction of gold.

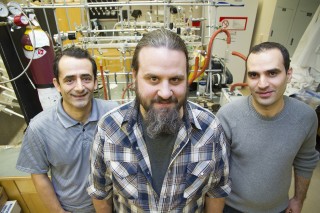

University of Saskatchewan research could revolutionize the gold extraction industry. Loghman Moradi, Stephen Foley and Hiwa Salimi (l to r) have discovered a chemical solution that extracts gold with less expense, time and and environmental cost than other current industry practices. (Kris Foster)

University of Saskatchewan research could revolutionize the gold extraction industry. Loghman Moradi, Stephen Foley and Hiwa Salimi (l to r) have discovered a chemical solution that extracts gold with less expense, time and and environmental cost than other current industry practices. (Kris Foster)

Foley, together with his research associate Loghman Moradi and PhD student Hiwa Salimi, discovered a new eco-friendly and cost-effective way for recovering and recycling gold from electronic waste.

"We’ve found a simple, cheap and environmentally benign solution that extracts gold in seconds, and can be recycled and reused. This could change the gold industry" said Foley.

According to Foley, the major problem with gold is that it is one of the least reactive chemical elements, causing difficulties in dissolving gold. The common gold mining process needs a huge quantity of sodium cyanide, meaning it causes environmental issues. Recycling gold from electronic wastage, like circuits and computer chips, involves procedures that cause environmental issues and are also expensive.

The environmental effects of current practices can be devastating.

Stephen Foley, Associate Professor, Department of Chemistry, U of S

Annually more than 50 million tons of electronic waste is produced in the world per year, and 80% of this ends up in landfills.

The team from U of S have invented a technique, mixing acetic acid with very small amounts of another acid and an oxidant. This solution extracts gold efficiently, and without the environmental issues of current practices in the industry. The gold extraction is done under mild conditions, and the solutions dissolves gold at the fastest rate ever witnessed.

Gold is stripped out from circuits in about 10 seconds, leaving the other metals intact.

Stephen Foley, Associate Professor, Department of Chemistry, U of S

Foley stated that 5,000 liters of aqua regia is required to extract one kilogram of gold from printed circuit boards, and none of which can be recycled. With the new solution, one kilogram can be extracted using just 100 liters, which can all be recycled. One liter of this solution is priced at 50 cents.

Foley’s team have invented a cheaper process with faster extraction and lower toxicity. This approach could be capable of revolutionizing the gold mining process and the industry.

The team now aims to use this new process in large-scale gold recycling businesses.

Source:

University of Saskatchewan