Feb 12 2016

Loughborough University engineering experts are helping to improve lives in India by sharing essential knowledge of how to turn waste into clean energy.

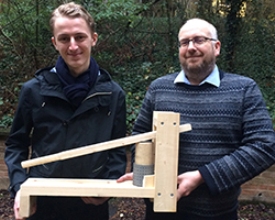

From left, Matthew Palmer and Dr Blanchard with the prototype wooden press. (©LoughboroughUniversity)

From left, Matthew Palmer and Dr Blanchard with the prototype wooden press. (©LoughboroughUniversity)

Dr Richard Blanchard, Lecturer in Renewable Energy at the Centre for Renewable Energy Systems Technology (CREST) at Loughborough University, has been joined by Chemical Engineering student Matthew Palmer in creating a cost-effective, alternative fuel source to firewood and charcoal.

In India, about 1 million people die annually from respiratory diseases due to household air pollution caused by smoke and fumes from burning firewood and charcoal. These fuels are often used in an open fire or simple stove with incomplete combustion, and result in a large amount of smoke.

To help empower disadvantaged women connected with the Russ Foundation in South India, Dr Blanchard built a simple prototype wooden press in order to make biomass briquettes. Matthew then enlisted the help of students Sahil Jhamb and Dominic Cowell, from the School of Business and Economics, to devise a briquette formula made from paper, sawdust and ash - materials which are easily accessible in India and often go to waste.

A metal version of the prototype press has since been made and installed at the charity to allow the women to create low-cost biomass briquettes, earn a wage and gain vocational skills as a result.

This has all been made possible thanks to MyIndia - a social enterprise project which aims to tackle fuel poverty in the country. It is led by students who make up Enactus Loughborough – an entrepreneurial action group established to make a positive change in the world.

And last year, the MyIndia team won the Santander 60 Second Pitch competition and were awarded £1,500 towards the project. Sahil was chosen as one of 10 finalists from universities across Great Britain after he posted a 60 second video about the positive impact biomass briquettes can have on people’s lives.

Dr Blanchard said: “MyIndia is an excellent example of a project which is making a real difference to people’s lives. Matthew initially asked me to help out and make a wooden prototype briquette press which could be easily replicated by the Russ Foundation. On my part I’m sharing knowledge and expertise to help people in poverty make a better life for themselves and their families; and ultimately be a part of a project that they can take ownership of – this is what it’s all about.”

Matthew added: “This project demonstrates the power of collaboration and I hope it inspires other student engineers to take up opportunities outside their degree and get involved with projects such as MyIndia. This is also a great example of students and lecturers working together to share simple engineering knowledge overseas. Without Dr Blanchard’s expertise, we wouldn’t have been able to help the Russ Foundation in the way that we did.”

To find out more about Enactus Loughborough, visit www.enactuslboro.co.uk.