May 3 2016

Researchers from UNSW have built flexible, full-sized, thin-film, solar cells that have the highest efficiency ever recorded so far, making ‘zero-energy’ buildings a potential reality. Zero-energy buildings produce as much power as they use up. These solar cells are non-toxic as well as economical.

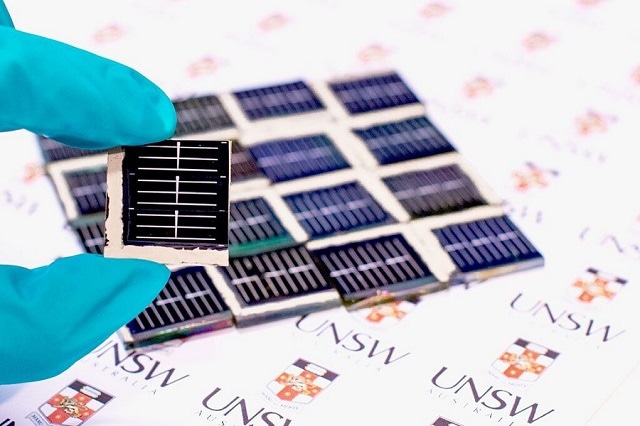

The new high-efficiency, low-toxicity solar cells developed by UNSW's Australian Centre for Advanced Photovoltaics. (Photo Credit- Wilson Da Silver/UNSW)

The new high-efficiency, low-toxicity solar cells developed by UNSW's Australian Centre for Advanced Photovoltaics. (Photo Credit- Wilson Da Silver/UNSW)

So far, two big challenges have hindered the progress of ‘zero-energy’ buildings. One was the cost of the currently used thin-film solar cells that are utilized in windows, roofs and façades, and the other was the scarcity and toxicity of the materials.

The UNSW team was headed by Dr Xiaojing Hao of the Australian Centre for Advanced Photovoltaics at the UNSW School of Photovoltaic and Renewable Energy Engineering. The new solar cell created by the team is based on a competing thin-film technology called CZTS. NREL, the USA’s National Renewable Energy Laboratory, confirmed this world leading 7.6% efficiency in a 1 cm2 area CZTS cell.

In comparison to its thin-film competitors, CZTS cells are produced using abundant materials - copper, zinc, tin and sulphur. CZTS also does not possess any toxicity issues, which are seen in its two thin-film competitors - cadmium-telluride (CdTe) and copper-indium-gallium-selenide (CIGS). Selenium and cadmium are toxic even at minuscule doses, while indium and tellurium are very rare.

This is the first step on CZTS’s road to beyond 20% efficiency, and marks a milestone in its journey from the lab to commercial product. There is still a lot of work needed to catch up with CdTe and CIGS, in both efficiency and cell size, but we are well on the way.

Dr Xiaojing Hao, School of Photovoltaic and Renewable Energy Engineering, UNSW

“In addition to its elements being more commonplace and environmentally benign, we’re interested in these higher bandgap CZTS cells for two reasons,” said Professor Martin Green, a mentor of Dr Hao.

“They can be deposited directly onto materials as thin layers that are 50 times thinner than a human hair, so there’s no need to manufacture silicon ‘wafer’ cells and interconnect them separately,” he added. “They also respond better than silicon to blue wavelengths of light, and can be stacked as a thin-film on top of silicon cells to ultimately improve the overall performance.”

As CZTS solar cells can be deposited on a variety of surfaces, the UNSW researchers believe that they are well on their way to building thin-film photovoltaic cells that can be firm or flexible, durable and adequately economical to be broadly integrated into buildings to produce electricity from the sunlight that hits structures such as façades, roof tiles, glazing, and windows.

This could happen sooner than expected as CZTS is cheaper and easier to transport from the lab to the real world than other thin-film solar cells, as the commercialized manufacturing method is readily available. UNSW is partnering with many large companies that are eager to advance applications much before it realizes 20% efficiency, probably in the next few years, according to Hao.

I’m quietly confident we can overcome the technical challenges to further boosting the efficiency of CZTS cells, because there are a lot of tricks we’ve learned over the past 30 years in boosting CdTe and CIGS and even silicon cells, but which haven’t been applied to CZTS.

Dr Xiaojing Hao, School of Photovoltaic and Renewable Energy Engineering, UNSW

At present, thin-film photovoltaic cells, such as CdTe, are predominantly used in large solar power farms, as the toxicity in cadmium makes them inappropriate for residential systems, while CIGS cells are widely used in Japan on rooftops.

First Solar, a US$5 billion company, specializing in large-scale photovoltaic systems, depends wholly on CdTe. CIGS is the favored technology of China's Hanergy, the world’s largest thin-film solar power company.

Thin-film technologies such as CIGS and CdTe are also popular as they are physically flexible, which promotes its use in potential applications including roofing membranes, curved surfaces, or translucent and transparent structures like skylights and windows. However, the construction sector is wary of the level of the toxicity in these technologies after learning from the history with asbestos. Scarcity of the materials also makes these thin-film technologies less appealing, as costs will increase as demand rises. Regardless of this, the global market for building-integrated photovoltaics (BIPV) is valued at US$1.6 billion.

Hao believes CZTS’s low cost, non-toxic environmental profile and abundance of materials will propel builders and architects to use thin-film solar panels in buildings on a wider scale.

Until now, many architects have replied on traditional solar panels that are produced from crystalline silicon. Although they are more economical than CZTS cells, solar panels do not offer the same versatility for curved surfaces and other odd geometries required to easily combine into building designs.