Jun 7 2016

Hydrogen-powered cars could soon become a reality with a new, radical technique process that enables efficient sourcing of hydrogen from liquid formic acid.

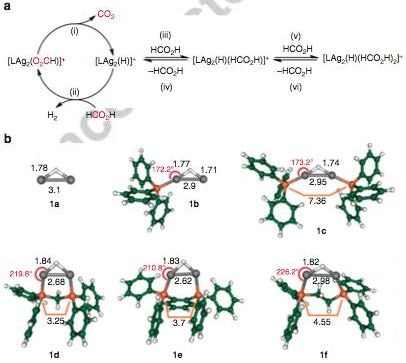

How the catalyst works. (CREDIT: University of Melbourne)

How the catalyst works. (CREDIT: University of Melbourne)

The idea of producing hydrogen from formic acid has never been considered to be practical. This is mainly because waste by-products are produced during the process, and also hydrogen can decompose only at high temperatures.

However, an international team of scientists, headed by Professor Richard O'Hair of University of Melbourne have succeeded in designing a molecular catalyst to overcome this problem. This molecular catalyst forces formic acid to generate only carbon dioxide and hydrogen and that too at 70°C temperature,

Professor O'Hair, from the University of Melbourne’s School of Chemistry and Bio21 Institute partnered with Professors Philippe Dugourd from the University of Lyon, Philippe Maitre from the University of Paris South, Bonači?-Koutecky? from the Humboldt-University Berlin, and Dr. Roger Mulder from CSIRO Manufacturing to undertake this study.

At a molecular level, it presents a major breakthrough in the field of catalyst design. Highly selective chemical reactions can be produced by formulating such catalysts.

One of the grand challenges for chemists today is to develop perfect chemical reactions that proceed with 100 per cent yield and 100 per cent selectivity without forming any waste products.

Professor O'Hair said.

"With formic acid, the aim was to transform it into hydrogen and carbon dioxide, which could really lend itself to the important practical applications of hydrogen energy in the transport sector."

Although hydrogen and carbon dioxide are obtained successfully in this approach, the main goal of future studies would be to produce sources of hydrogen that have zero emissions.

A series of silver complexes was designed by the research team using a set of strong gas-phase techniques, and the reaction between these silver complexes and formic acid was examined.

The research team was successful in identifying and arranging the most suitable catalyst that could efficiently exploit the production process of hydrogen and carbon dioxide.

Mr Athanasios Zavras, the first author of the study and a PhD student at the University of Melbourne, stated that it was an exciting experience to witness the initial gas-phase results being substantiated with the NMR instrument.

"We were glued to our seats that day," he said.

"I prepared solutions containing well-defined amounts of the same silver, salt and ligand combination and these were studied with a NMR that allowed us to incrementally increase the temperature from 25°C and track the formation of products.

There was no reaction for a while, but we persevered and at 70°C, we unequivocally identified the production of hydrogen gas and carbon dioxide. It was an extremely exciting moment.

Mr Athanasios Zavras

Presently, the deficit of refueling infrastructure for hydrogen power continues to be a major issue. According to the researchers, such problems can be resolved by using of liquid formic acid.

Although the new catalyst design is a remarkable innovation in meeting the hydrogen energy needs, Professor O'Hair highlights the various barriers that still need to be overcome. For instance, carbon dioxide production and how it can possibly be recycled to reproduce formic acid.

The study was funded by the Australian Research Council, and has been reported in the journal Nature Communications.