Jun 30 2016

The natural component of plant cell walls, the scaffolding that covers every cell and plays an important role in the ability of plants to grow against gravity and reach heights ranging from unkempt grasses to the elevated splendor of redwoods is lignin. However lignin poses a problem for researchers that are keen to transform plant biomass to biofuels and other sustainable bio-products. Lignin makes it difficult to break down the plant matter so its carbon-rich building blocks could be transformed into forms appropriate for running automobiles or producing energy.

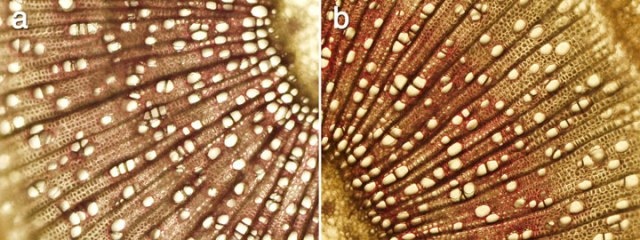

Microscopic images of wood tissues from wild type (a) and transgenic (b) aspen trees show similar anatomical and structural features, suggesting that the transgenic plant maintains normal growth and wood formation even with altered lignin composition. CREDIT: Brookhaven National Laboratory

Microscopic images of wood tissues from wild type (a) and transgenic (b) aspen trees show similar anatomical and structural features, suggesting that the transgenic plant maintains normal growth and wood formation even with altered lignin composition. CREDIT: Brookhaven National Laboratory

Engineering plants that contain less lignin could be the answer. However earlier attempts to do this have regularly led to weaker plants and short growth, effectively stopping biomass production.

By modifying a new enzyme that is involved in lignin synthesis, the U.S. Department of Energy's Brookhaven National Laboratory researchers and colleagues have changed the lignin in aspen trees in a manner that raises biofuel access to building blocks without plant growth inhibition. Their research, published in Nature Communications, resulted in around 50% rise in yield of ethanol from healthy aspen trees whose woody biomass released 62% more simpler sugars than inhabitant plants.

Our study provides a useful strategy for tailoring woody biomass for bio-based applications.The lignin forms a barrier of sorts around the other polymers. Digestive enzymes can't get through to break down the cellulose and hemicellulose to release their simple sugars.

Chang-Jun Liu, Biologist, Brookhaven

Lignin constitutes 20% of aspen's woody structures, with hemicellulose and cellulose polymers making up roughly 45 and 25%, together with other minor components.

Earlier work, like Liu's research altering enzymes taking part in lignin synthesis, has proven that decreasing or changing plants' lignin content can create more digestible woody biomass. However most of these methods, mainly those that radically decreased lignin content, resulted in weaker plants and harsh reductions in biomass yield, making these plants inappropriate for large-scale cultivation.

The researchers investigated an innovative novel strategy to alter lignin's structure on the basis of thorough examination of enzyme structures that were earlier solved by Liu and his colleagues through the usage of x-rays at the National Synchrotron Light Source (NSLS), which is a DOE Office of Science User Facility at Brookhaven Lab, currently substituted by a brighter NSLS-II.

`The results of this work was reported in Plant Cell (2012) and the Journal of Biological Chemistry (2010 and 2015). This was partially an effort to comprehend the mechanism of enzymes of selectivity. The researchers also earlier looked for a series of variations of the enzyme, called monolignol 4-O-methyltransferase, some of which effectively altered the structure of lignin building blocks so they would not be included into the lignin polymer.

The researchers used biochemical tests to spot an alternate of monolignol 4-O-methyltransferase that had a minor chemical "preference" for reacting with one particular kind of lignin precursor. The researchers said that this alternate could lower the development of a specific lignin constituent.

The researchers transplanted this variant gene into a fast-growing strain of aspen trees, which is a model for the additional trees within the poplar family, which have extensive potential for bioenergy production due to their ability to grow in different regions and on non-agricultural land. The researchers grew the modified aspen trees beside crude control trees in a greenhouse on Brookhaven's property.

Modified Cell Walls Had More Sugar

The trees that formed the engineered enzyme had less total lignin in their cell walls. On further analysis, the researchers discovered that these trees also had changed lignin structure, with a noteworthy decrease in the level of one of the main types of lignin constituents usually found in aspen trees. These discoveries were also confirmed using 2D NMR spectroscopic imaging by a research group headed by John Ralph of the University of Wisconsin and the Great Lakes Bioenergy Research Center, a DOE Bioenergy Research Center. The engineered trees had a smaller amount "labile" lignin, whilst the left over lignin parts became structurally more condensed, thereby forming more number of cross-linkages between the polymers.

We expected that this condensed, more cross-linked lignin might make the plants even harder to digest, but found that wood containing these structures released up to 62 percent more simple sugars when treated with digestive enzymes.

Chang-Jun Liu, Biologist, Brookhaven

This modified wood yielded ethanol almost 50% more than the ethanol yield of wood obtained from crude control trees.

The researchers discovered that their method of changing lignin content and composition also raised the making of cellulose fibers, the major source of fermentable sugars in the cell wall, by imaging aspen wood samples with IR light at NSLS. This raise in cellulose content might contribute partly to the improved release of simple sugars. The alterations in lignin and cell wall structures did not have an effect on the growth of the engineered aspens. The biomass yields and wood densities were similar to those of the control trees.

These data suggest that lignin condensation itself is not a critical factor affecting the digestibility of the cell wall. The findings also support the idea that engineering the enzymes that modify lignin precursors represents a useful biotechnological solution for effectively tailoring the digestibility of poplar-family woody biomass to generate feedstocks for biofuel production. It's gratifying when fundamental studies of enzyme function, such as the findings that underpin this work, can be translated to contribute to solving real-world problems.

Chang-Jun Liu, Biologist, Brookhaven

The DOE Office of Science funded this research.