Oct 6 2016

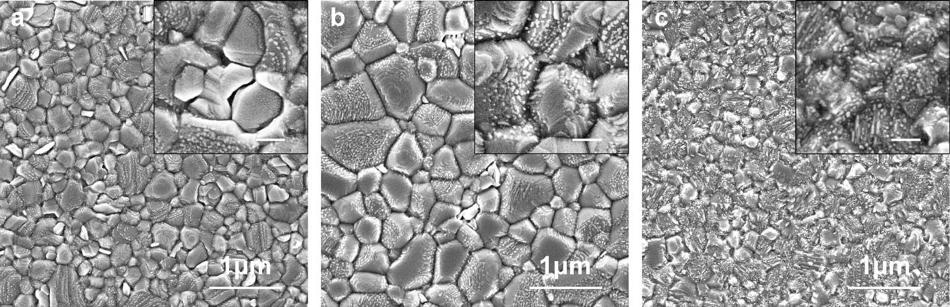

This is a comparison of grain boundaries in MAPbI3 perovskite films following thermal annealing (a), DMF solvent annealing (b), and methylamine post annealing treatment. The methylamine post annealing treatment shows the most improvement, as the grain boundaries become fused and less defined after application.

(CREDIT - Yan Jiang)

This is a comparison of grain boundaries in MAPbI3 perovskite films following thermal annealing (a), DMF solvent annealing (b), and methylamine post annealing treatment. The methylamine post annealing treatment shows the most improvement, as the grain boundaries become fused and less defined after application.

(CREDIT - Yan Jiang)

The importance of renewable energy sources is gaining more attention than ever since the environmental cost of conventional energy sources began to rise and the supply of fossil fuels became a finite resource.

The hurdle however lies in efficiently harnessing solar energy for regular use. Although silicon-based solar cells are capable of trapping solar energy, they are expensive to manufacture on an industrial scale.

A recent study from the Energy Materials and Surface Sciences Unit at the Okinawa Institute of Science and Technology Graduate University (OIST), led by Prof. Yabing Qi, has explored the use of organo-metal halide perovskite films in solar cells.

Perovskite films are basically highly crystalline materials that can be produced by a large number of varied chemical combinations and can be deposited economically. Some of the latest publications from Prof. Qi’s lab cover three different areas of innovation in the study of the perovskite film: a new post annealing treatment to boost perovskite stability and efficiency, an observation of the decomposition products of a specific perovskite, and a new means of creating perovskites that keeps up the solar efficiency when scaled up.

For perovskite films to be as useful as solar cells, they should be able to harvest solar energy with high efficiency in a cost effective manner, be comparatively easy to manufacture, and be able to handle the outdoor environment over an extended period of time.

Recently, Dr. Yan Jiang in Prof. Qi’s lab has published a research in Materials Horizons that may help enhance the solar efficiency of the organo-metal halide perovskite MAPbI3. He found out that the use of a methylamine solution during post-annealing caused a decrease in issues linked with grain boundaries. Grain boundaries are noticeable as gaps between crystalline domains and can lead to unnecessary charge recombination. This is a general occurrence in perovskite films and can decrease their efficiency, making the enhancement of grain boundary issues vital to maintain high device performance. Dr. Jiang’s novel post annealing treatment generated solar cells that had fused grain boundaries, decreased charge recombination, and displayed superior conversion efficiency of 18.4%. His treated perovskite films also displayed excellent reproducibility and stability, making his technique practical for production of solar cells at industrial scale.

One of the main downsides to the use of perovskites in comparison to silicon in solar cells is their comparatively short lifespan. In order to develop a solar cell that can survive the outdoor environment over an extended period of time, it is vital to establish the key products of perovskite decomposition. Previous research on MAPbI3 perovskite films brought about the conclusion that the gas products of thermal degradation of this material were hydrogen iodide (HI) and methylamine (CH3NH2).

However, stimulating new research from Dr. Emilio J. Juarez-Perez, also in Prof. Qi’s lab, published in Energy & Environmental Science, reveals that main gas products of degradation are ammonia (NH3) and methyliodide (CH3I) instead. Dr. Juarez-Perez used a blend of mass spectrometry (MS) and thermal gravimetric differential thermal analysis (TG-DTA) to appropriately establish both the chemical nature and mass loss of these products. Since the products of decomposition are now known, researchers can explore ways to stop material degradation, which in turn would lead to more stable materials for use in the future.

A persistent issue in academic research is frequently the failure to scale up experiments to industry level. While perovskite films can be produced with comparative ease on a small scale at a laboratory, they are cumbersome to replicate on the large scale. A recent research from Dr. Matthew Leyden in the Journal of Materials Chemistry A offers the possibility to make industrial production of perovskites a lot simpler. His work involves chemical vapor deposition, an economical process frequently used in industry, to develop large solar cells and modules of FAPbI3 perovskites. This is one of the initial exhibitions of perovskite solar cells and modules fabricated by a technique extensively used in industry, making the large-scale production of perovskite films more practical. The solar cells and modules made are considerably larger, e.g., 12cm2, than those normally studied in academia, about <0.3cm2.

These solar modules demonstrate improved thermal stability and comparatively high efficiencies, which is remarkable as several perovskite solar cells lose efficiency significantly as they are scaled up, making this type of research practical for commercial purposes.

The research work from Prof. Qi’s research unit has moved perovskite solar cells one step closer to large-scale production by offering solutions to issues of efficiency, scalability and life-span. Going forward, more exciting research will be achieved as the unit works towards making the dream of using cost-effective renewable energy resources a reality.