Mar 1 2017

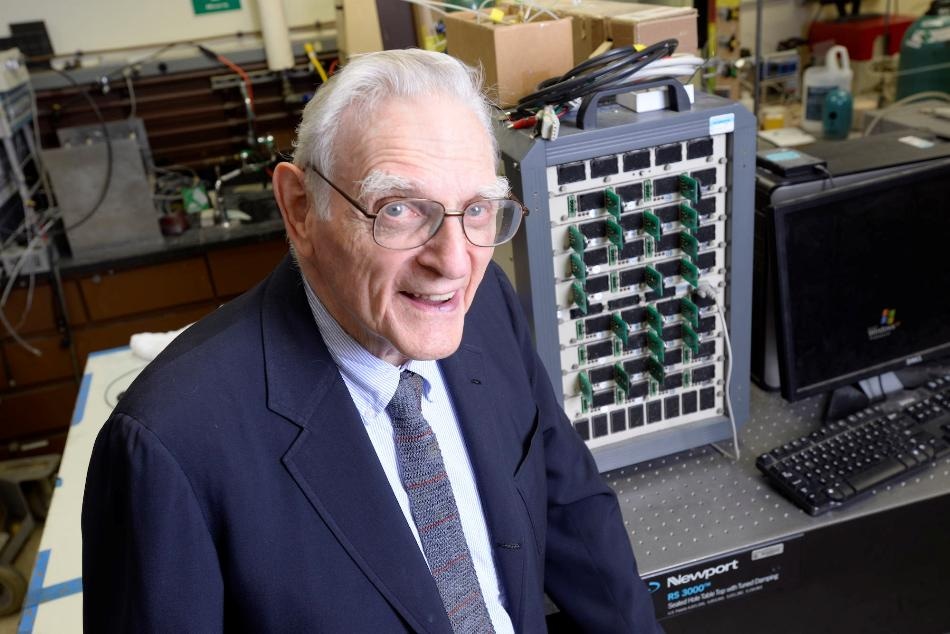

John Goodenough, professor in the Cockrell School of Engineering at The University of Texas at Austin and co-inventor of the lithium-ion battery, in the battery materials lab he oversees. Credit: Cockrell School of Engineering

John Goodenough, professor in the Cockrell School of Engineering at The University of Texas at Austin and co-inventor of the lithium-ion battery, in the battery materials lab he oversees. Credit: Cockrell School of Engineering

The first all-solid-state battery cells that could to longer-lasting, faster-charging, safer rechargeable batteries for stationary energy storage, electric cars and handheld mobile devices have been developed by a team of engineers headed by John Goodenough, a 94-year-old professor in the Cockrell School of Engineering at The University of Texas at Austin and co-inventor of the lithium-ion battery.

Goodenough’s most recent breakthrough, is a cost-effective all-solid-state battery that is noncombustible and has prolonged cycle life (battery life) with fast rates of charge and discharge and a high volumetric energy density, was completed in collaboration with Cockrell School senior research fellow Maria Helena Braga.

Cost, safety, energy density, rates of charge and discharge and cycle life are critical for battery-driven cars to be more widely adopted. We believe our discovery solves many of the problems that are inherent in today’s batteries.

John Goodenough, Professor, Cockrell School of Engineering

The team demonstrated that their newly developed battery cells have almost three times as much energy density as the existing lithium-ion batteries. A higher density means that a car can drive additional miles between charges, as the energy density of a battery cell gives an electric vehicle its driving range.

An increased number of charging and discharging cycles is also allowed by the UT Austin battery formulation, which equates to longer-lasting batteries, and a faster recharging rate (minutes rather than hours).

Liquid electrolytes are used by today's lithium-ion batteries in order to transport the lithium ions between the anode, the battery’s negative side, and the cathode the battery’s positive side. Charging of a battery cell too fast can result in the formation of “metal whiskers” or dendrites that will travel through liquid electrolytes, developing a short circuit that can lead to explosions and fires.

The researchers depend on glass electrolytes, instead of liquid electrolytes, as the glass electrolytes enable the application of alkali-metal anode without the development of dendrites.

The energy density of a cathode is increased and a prolonged cycle life is delivered with the use of an alkali-metal anode (potassium, sodium or lithium), which is not possible in the case of standard batteries. The researchers conducted a number of experiments where the cells developed by them demonstrated over 1,200 cycles with low cell resistance.

When used in a car this type of battery could perform well in subzero degree weather as the solid-glass electrolytes can operate or contain increased conductivity, at -20 °C. This is the very first all-solid-state battery cell capable of operating below 60 °C.

While at the University of Porto in Portugal, Braga and her colleagues began to develop solid-glass electrolytes. Almost two years earlier, she started to collaborate with Goodenough and researcher Andrew J. Murchison at UT Austin.

Braga stated that Goodenough introduced an understanding of the properties and composition of the solid-glass electrolytes that led to a new version of the electrolytes. This new version has now been patented through the UT Austin Office of Technology Commercialization.

The glass electrolytes of the engineers enable them to plate and strip alkali metals on the anode and cathode sides without dendrites, which simplifies the battery cell fabrication process.

Yet another advantage is the fact that the battery cells can be developed from earth-friendly materials.

The glass electrolytes allow for the substitution of low-cost sodium for lithium. Sodium is extracted from seawater that is widely available.

Maria Helena Braga, Senior Research Fellow, Cockrell School of Engineering

Goodenough and Braga are both continuing to focus on improving their battery-related research and are also working on many patents. In the short term, they expect to work with battery makers in order to produce and test their new materials in energy storage devices and electric vehicles.

This research receives support from UT Austin, however there are no grants linked with this work. License agreements are being actively negotiated by the UT Austin Office of Technology Commercialization with several companies engaged a wide range of battery-related industry segments.