Mar 2 2017

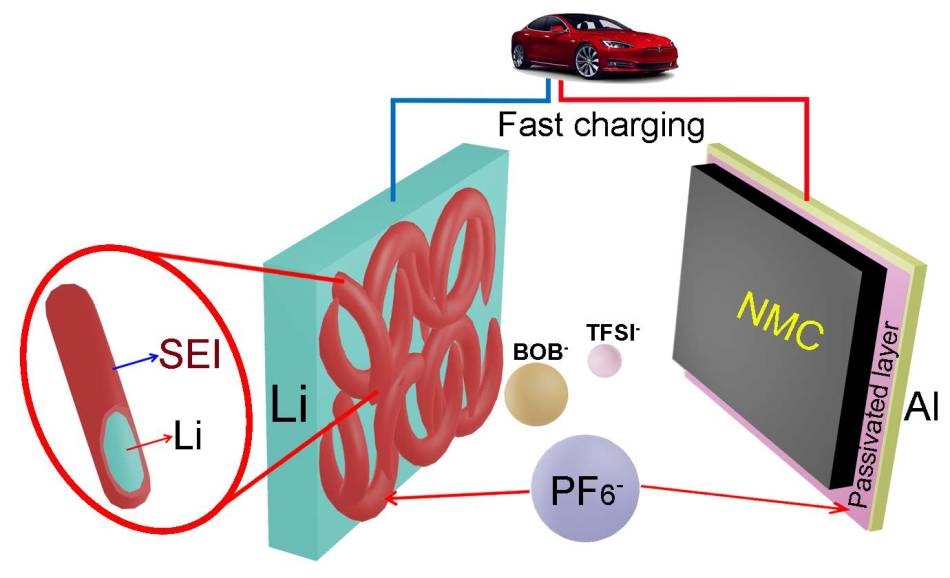

An artist's illustration shows how PNNL's addition of the chemical lithium hexafluorophosphate to a dual-salt, carbonate solvent-based electrolyte makes rechargeable lithium-metal batteries stable, charge quickly, have a high voltage, and go longer in between charges. (Credit: PNNL)

An artist's illustration shows how PNNL's addition of the chemical lithium hexafluorophosphate to a dual-salt, carbonate solvent-based electrolyte makes rechargeable lithium-metal batteries stable, charge quickly, have a high voltage, and go longer in between charges. (Credit: PNNL)

Researchers have discovered that adding a tiny bit of something new to the electrolyte in a battery gives energy storage devices more juice per charge than currently used common rechargeable batteries.

New, early-stage research shows that incorporating a small quantity of the chemical lithium hexafluorophosphate to a dual-salt, carbonate solvent-based electrolyte can make rechargeable lithium-metal batteries stable, charge fast, and possess a high voltage.

A good lithium-metal battery will have the same lifespan as the lithium-ion batteries that power today's electric cars and consumer electric devices, but also store more energy so we can drive longer in between charges.

Wu Xu, Chemist, Department of Energy’s Pacific Northwest National Laboratory

Xu is a corresponding author on a paper published in the Nature Energy journal today.

Battery basics

Most of the rechargeable batteries currently used are lithium-ion batteries. These batteries have two electrodes: one that is positively charged and has lithium, and another that is negative and commonly made of graphite. Electricity is produced when electrons flow through a wire that links the two.

To control the electrons, positively charged lithium atoms travel from one electrode to the other via another path, the electrolyte solution in which the electrodes are placed. However, graphite cannot store a lot of energy; limiting the quantity of energy a lithium-ion battery can offer electric vehicles and smartphones.

In the 1970s, researchers used lithium metal for the negative electrode, referred to as an anode, when they first developed lithium-based rechargeable batteries. Lithium was selected as it has ten times additional energy storage capacity compared to graphite.

The problem faced by the researchers was that the lithium-carrying electrolyte reacted with the lithium anode, which resulted in microscopic lithium nanoparticles and branches known as dendrites to grow on the anode surface. This caused those batteries to fail.

Several attempts to resolve the dendrite issue have been made to tweak rechargeable batteries over the years. Researchers tried out other materials such as graphite for the anode. They also tried coating anodes with protective layers, while others attempted to create electrolyte additives.

Some solutions removed dendrites but resulted in impractical batteries with less power. In other techniques, dendrite growth was only slowed, but could not be stopped.

Next-generation storage

Thinking the currently available rechargeable lithium-ion batteries with graphite anodes could be close to their peak energy capacity, PNNL is once again analyzing the older design with lithium metal as an anode. Xu and colleagues were part of previous PNNL research searching for a better-performing electrolyte.

The electrolytes they used created either a battery that did not have the dendrites and was super-efficient but charged very gradually and could not function in higher-voltage batteries, or a faster-charging battery that was unpredictable and had low voltages.

Next, they attempted to add tiny amounts of a salt that is already used in lithium-ion batteries, lithium hexafluorophosphate, to their quick-charging electrolyte. They paired the latest juiced-up electrolyte with a lithium nickel manganese cobalt oxide cathode and a lithium anode. This turned out to be a winning combination, resulting in a quick, efficient, high-voltage battery.

The additive enabled a 4.3-volt battery that retained over 97 % of its original charge after 500 repeated charges and discharges, while carrying 1.75 milliAmps of electrical current per square centimeter of area. It took the battery approximately one hour to fully charge.

Inexpensive protection

The battery performed well largely because the additive helps produce a robust protective layer of carbonate polymers on the lithium anode of the battery. This thin layer prevents lithium from being consumed in unnecessary side reactions, which can ruin a battery.

Also, since the additive is already a well-known component of lithium-ion batteries, it is readily available and comparatively inexpensive. The small quantities required - only 0. 6% of the electrolyte by weight - should also further decrease the cost of the electrolyte.

Xu and his team continue to assess a number of ways to make rechargeable lithium-metal batteries feasible, including enhancing electrodes, electrolytes, and separators. Subsequent steps will specifically include making and analyzing larger quantities of their electrolyte, increasing material loading on the cathode, additionally enhancing the efficiency and capacity retention of a lithium-metal battery using their electrolyte, and trying a thinner anode.

This study was supported by the Department of Energy's Office of Energy Efficiency and Renewable Energy. Researchers performed microscopy and spectroscopy characterizations of battery materials at EMSL, the Environmental Molecular Sciences Laboratory, a DOE Office of Science national User Facility at PNNL. The battery electrodes were produced at DOE's Cell Analysis, Modeling, and Prototyping Facility at Argonne National Laboratory.