Apr 20 2017

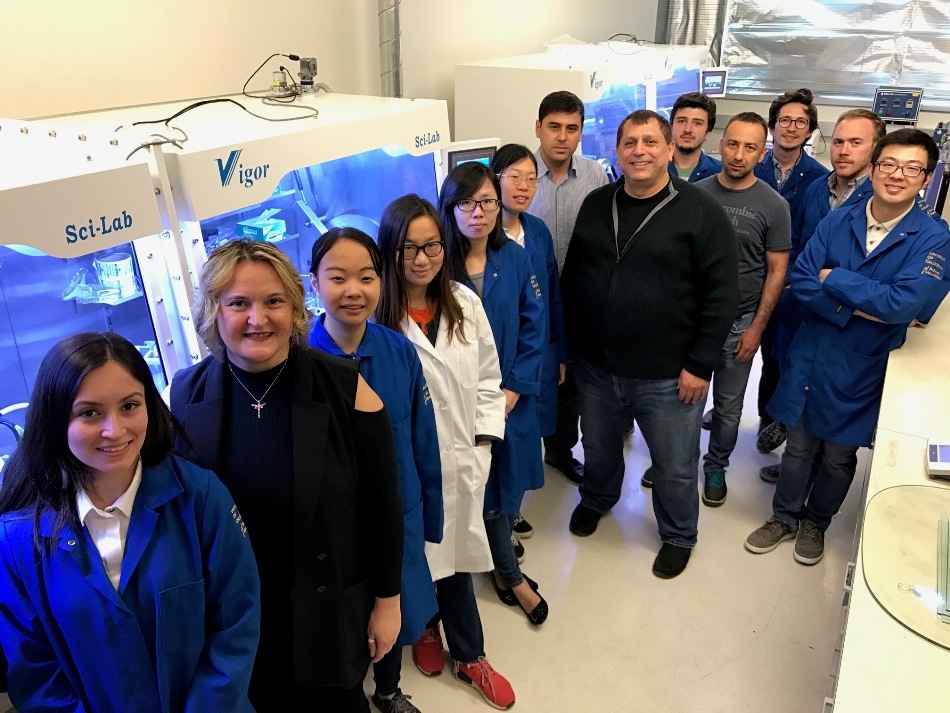

A team of battery researchers led by Cengiz Ozkan, professor of mechanical engineering, and Mihri Ozkan, professor of electrical engineering at UC Riverside. (Credit: University of California (UCR))

A team of battery researchers led by Cengiz Ozkan, professor of mechanical engineering, and Mihri Ozkan, professor of electrical engineering at UC Riverside. (Credit: University of California (UCR))

A research group at the University of California (UCR), Riverside’s Bourns College of Engineering has developed nanosilicon anodes for high-performance lithium-ion batteries, by simply using a low-cost chemical process and waste glass bottles.

The batteries will not only extend the range of plug-in hybrid electric vehicles and electric vehicles, but also provide extra power with fewer charges to laptops, cell phones, and similar personal electronics.

The study titled “Silicon Derived from Glass Bottles as Anode Materials for Lithium Ion Full Cell Batteries,” has been described in the Nature journal Scientific Reports. The project was headed by Cengiz Ozkan, professor of mechanical engineering, and Mihri Ozkan, professor of electrical engineering.

Every year, billions of waste glass bottles are disposed in landfills even with current recycling programs. This prompted the research team to ask whether silicon dioxide found in waste beverage bottles would be able to provide high purity silicon nanoparticles that can be subsequently used for lithium-ion batteries.

Compared to conventional graphite anodes, silicon anodes can store as much as 10 times more energy. However, shrinkage and expansion during charge and discharge cycles make these silicon anodes unstable. This problem can be reduced by downsizing silicon to the nanoscale. By integrating a low-cost chemical reaction and an abundant and relatively pure form of silicon dioxide, the team developed lithium-ion half-cell batteries that are capable of storing almost four times more energy than that of traditional graphite anodes.

The researchers applied a three-step process to produce the anodes. In this process, glass bottles were crushed and ground into a fine white power, followed by a magnesiothermic reduction to convert silicon dioxide into nanostructured silicon, and finally coating the silicon nanoparticles with carbon to enhance their stability as well as energy storage properties.

In laboratory tests, coin cell batteries that were made using the glass bottle-based silicon anodes considerably outperformed conventional batteries, as predicted. Excellent electrochemical performance was demonstrated by carbon-coated glass derived-silicon (gSi@C) electrodes, with a capacity of ~1420 mAh/g at C/2 rate following 400 cycles.

Changling Li, paper’s lead author and a graduate student in materials science and engineering, informed that a single glass bottle provides sufficient nanosilicon for hundreds of three-five pouch cell batteries or coin cell batteries

We started with a waste product that was headed for the landfill and created batteries that stored more energy, charged faster, and were more stable than commercial coin cell batteries. Hence, we have very promising candidates for next-generation lithium-ion batteries.

Changling Li, Graduate Student, UCR

This is the latest research in a series of projects headed by Cengiz Ozkan and Mihri to make lithium-ion battery anodes from environmentally friendly materials. In the past, studies have primarily focused on creating and testing anodes from sand, portabella mushrooms, and diatomaceous (fossil-rich) earth.

Apart from Mihri, Cengiz Ozkan and Li, other contributors include graduate students Wei Wang, Chueh Liu, Zafer Mutlu, Kazi Ahmed, Jeffrey Bell, and Rachel Ye. The UC-Riverside and UC Faculty Climate Champion initiative provided financial support for this work.

A patent application for the above inventions has been filed by the UCR Office of Technology Commercialization.

The Glass is Greener