May 22 2017

Critical concerns have been raised by a number of studies regarding the promise of corn ethanol’s ability to alleviate climate change and minimize dependence on fossil fuels.

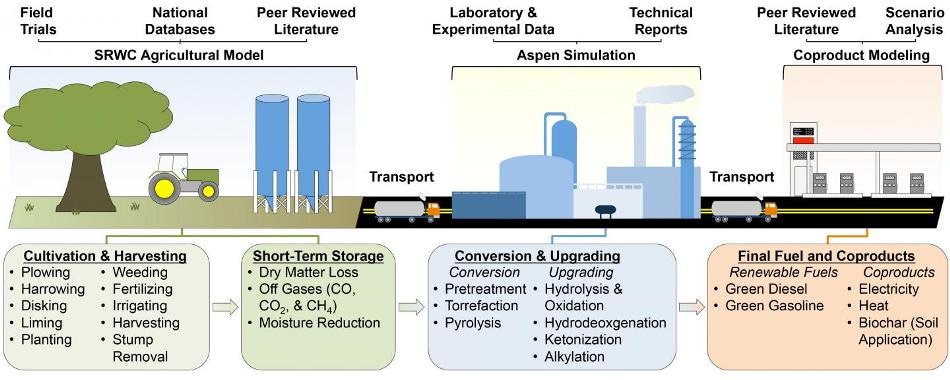

This is a schematic showing the stages modeled in the biomass-to-fuel life cycle assessment. This image first appeared in the Royal Society of Chemistry journal Energy & Environmental Science, Issue 5, 2017. (CREDIT - Vikas Khanna)

This is a schematic showing the stages modeled in the biomass-to-fuel life cycle assessment. This image first appeared in the Royal Society of Chemistry journal Energy & Environmental Science, Issue 5, 2017. (CREDIT - Vikas Khanna)

Some of the studies have proposed that after a complete life cycle assessment—meaning an examination of environmental impact throughout all stages of a product’s life—biofuels such as corn ethanol may not offer any greenhouse gas emissions reductions compared to petroleum fuels.

The Royal Society of Chemistry journal Energy & Environmental Science recently published a study by a team from the University of Pittsburgh and the University of Oklahoma examining the full life cycle impact of one potential “second-generation biofuel” created from short-rotation oak. The research discovered that second-generation biofuels produced from perennial grasses and managed trees may provide a viable fuel resource.

“Multistage torrefaction and in situ catalytic upgrading to hydrocarbon biofuels: analysis of life cycle energy use and greenhouse gas emissions” (DOI: 10.1039/C7EE00682A) described a novel approach to the manufacture of second-generation biofuel while also broadly accounting for all of the steps involved in the total supply chain.

Corn ethanol environmental impacts weren’t really studied until after its commercialization. The great thing about this project is it addresses full life cycle sustainability questions of new fuel sources before they come up later down the road.

Vikas Khanna, assistant professor of civil and environmental engineering at the University of Pittsburgh and the study’s corresponding author.

In 2007, the United Nations called for a five-year moratorium on food-based (or first-generation) biofuels because of apprehensions that they would consume farmland and cause global food shortage. Dr. Khanna and his team’s research used wood from oak trees, as they can be harvested throughout the year and minimize the need for large-scale storage infrastructure.

Second-generation biofuels differ from first generation biofuels because they don’t come directly from food crops like corn and soy. They include woody crops, perennial grasses, agricultural and forest residues, and industrial wastes.

Dr. Khanna

An important metric for establishing the efficacy of fuel is the Energy Return on Investment (EROI) ratio. The EROI of petroleum crude manufacture remains high at approximately 11:1, meaning an investment of one unit of energy will give 11 units of energy. However, the EROI has been progressively reducing since 1986 and will continue to deteriorate as fossil fuels become more limited and difficult to access. When researchers examine potentially promising energy sources, they aim for a ratio greater than 1:1. Corn derived ethanol, for instance, has an EROI of 1.3:1. The research discovered the median EROI for multistage second-generation biofuel systems ranges from 1.32:1 to 3.76:1.

The Energy Independence and Security Act of 2007 stipulates that cellulosic biofuels, like the ones used in the research, must outdo the greenhouse gas emissions of fossil fuels by minimizing relative emissions by 60% to obtain economic incentives from the government. The research exceeded minimum requirements and exhibited an 80% decrease in greenhouse gas emissions compared to baseline petroleum diesel. Furthermore, there was a 40% decrease in hydrogen consumption compared to a single-stage pyrolysis system.

Pyrolysis is the process of heating biomass to high temperatures in the absence of oxygen to and create biofuel. If it’s done quickly, in one stage, a lot of carbon will be lost. Our research showed that a multistage, lower temperature system of pyrolysis can increase the carbon chain length, create more liquid fuel and improve the energy output of the entire process.

Dr. Khanna

The study’s co-authors include: George G. Zaimes, senior engineer at KeyLogic and former PhD advisee under Dr. Khanna; Andrew W. Beck, graduate research assistant at the University of Pittsburgh; Rajiv R. Janupala, research assistant at the University of Oklahoma; and University of Oklahoma faculty members Daniel E. Resasco, Steven P. Crossley and Lance L. Lobban.