Jun 23 2017

Researchers have created a new low-temperature catalyst for making high-purity hydrogen gas and using up carbon monoxide (CO) at the same time. The discovery could enhance the performance of fuel cells that function on hydrogen fuel but can be poisoned by CO. The details of the discovery have been reported in a paper published online in the journal Science.

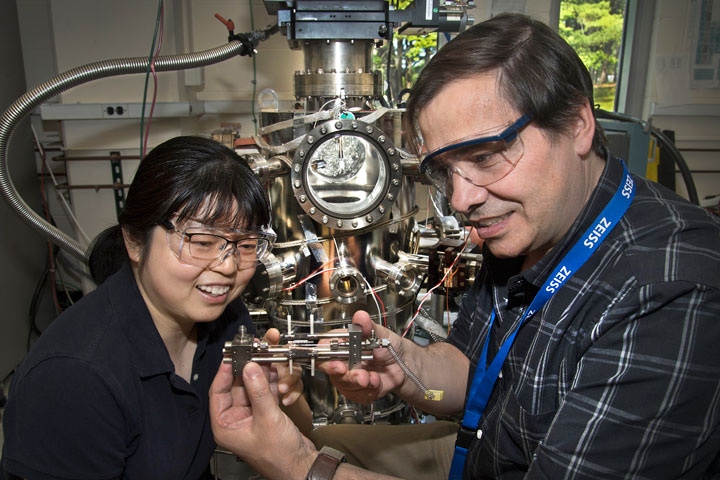

Brookhaven Lab chemists Ping Liu and José Rodriguez helped to characterize structural and mechanistic details of a new low-temperature catalyst for producing high-purity hydrogen gas from water and carbon monoxide. (Credit: Brookhaven Lab)

Brookhaven Lab chemists Ping Liu and José Rodriguez helped to characterize structural and mechanistic details of a new low-temperature catalyst for producing high-purity hydrogen gas from water and carbon monoxide. (Credit: Brookhaven Lab)

“This catalyst produces a purer form of hydrogen to feed into the fuel cell,” said José Rodriguez, a Chemist at the U.S. Department of Energy’s (DOE) Brookhaven National Laboratory. Rodriguez and colleagues in Brookhaven’s Chemistry Division—Ping Liu and Wenqian Xu—were among the team of Researchers who assisted in characterizing the mechanistic and structural details of the catalyst, which was synthesized and analyzed by Collaborators at Peking University in an effort guided by Chemistry Professor Ding Ma.

Since the catalyst works at low pressure and low temperature to convert water (H2O) and carbon monoxide (CO) to hydrogen gas (H2) and carbon dioxide (CO2), it could also lower the cost of working this so-called “water gas shift” reaction.

With low temperature and pressure, the energy consumption will be lower and the experimental setup will be less expensive and easier to use in small settings, like fuel cells for cars.

José Rodriguez, Chemist, U.S. Department of Energy’s (DOE) Brookhaven National Laboratory

The gold-carbide connection

The catalyst is composed of bunches of gold nanoparticles layered on a molybdenum-carbide substrate. This chemical combination is quite different from the oxide-based catalysts used to work the water gas shift reaction in huge industrial hydrogen production plants.

Carbides are more chemically reactive than oxides and the gold-carbide interface has good properties for the water gas shift reaction; it interacts better with water than pure metals. The group at Peking University discovered a new synthetic method, and that was a real breakthrough. They found a way to get a specific phase—or configuration of the atoms—that is highly active for this reaction.

José Rodriguez, Chemist, U.S. Department of Energy’s (DOE) Brookhaven National Laboratory

Brookhaven Researchers played a major role in interpreting the reasons for the high catalytic activity of this configuration. Rodriguez, Wenqian Xu, and Siyu Yao (then a Student at Peking University but currently a Postdoctoral Research Fellow at Brookhaven) conducted structural analysis using x-ray diffraction at the National Synchrotron Light Source (NSLS) while the catalyst was operating under technical or industrial conditions. These operando experiments showed vital details about how the structure altered under various operating conditions, including at varied temperatures.

Possessing those structural details, Zhijun Zuo, a Visiting Professor at Brookhaven from Taiyuan University of Technology, China, and Brookhaven Chemist Ping Liu helped to create models and a theoretical framework to describe why the catalyst functions the way it does, using computational resources at Brookhaven’s Center for Functional Nanomaterials (CFN).

“We modeled different interfaces of gold and molybdenum carbide and studied the reaction mechanism to identify exactly where the reactions take place—the active sites where atoms are binding, and how bonds are breaking and reforming,” she said.

Additional research at Oak Ridge National Laboratory’s Center for Nanophase Materials Sciences (CNMS), the Advanced Light Source (ALS) at Lawrence Berkeley National Laboratory, and two synchrotron research facilities in China helped to enhance the researchers’ understanding.

“This is a multipart complex reaction,” said Liu, but she noted one vital factor: “The interaction between the gold and the carbide substrate is very important. Gold usually bonds things very weakly. With this synthesis method we get stronger adherence of gold to molybdenum carbide in a controlled way.”

That configuration stabilizes the main intermediate that forms as the reaction progresses, and the stability of that intermediate establishes the rate of hydrogen production, she said.

The Brookhaven team will pursue analyzing this and other carbide catalysts with new capabilities at the National Synchrotron Light Source II (NSLS-II), a new facility that opened at Brookhaven Lab in 2014, replacing NSLS and generating X-rays that are 10,000 times brighter. With these brighter X-rays, the Researchers are confident about capturing more details of the chemistry in action, including specifics of the intermediates that form throughout the reaction process to confirm the theoretical predictions made in this research.

The research at Brookhaven Lab was funded by the U.S. DOE Office of Science.

Additional funders for the total research project include: the National Basic Research Program of China, the Chinese Academy of Sciences, National Natural Science Foundation of China, Fundamental Research Funds for the Central Universities of China, and the U.S. National Science Foundation.