Sep 6 2017

To see fuel cells in action, a ride on the University of Delaware’s Fuel Cell bus will prove these cells can power vehicles in an eco-friendly way.

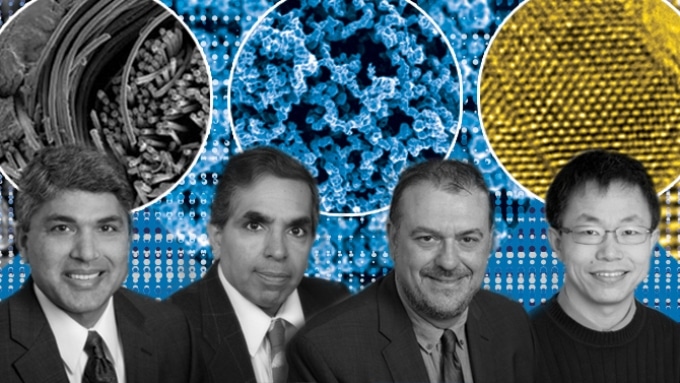

A team of UD engineering faculty members and department leaders brought their research groups together for a fuel cell innovation. This illustration includes Professors Ajay K. Prasad, Suresh G. Advani, Dionisios Vlachos and Yushan Yan. (Credit: University of Delaware)

A team of UD engineering faculty members and department leaders brought their research groups together for a fuel cell innovation. This illustration includes Professors Ajay K. Prasad, Suresh G. Advani, Dionisios Vlachos and Yushan Yan. (Credit: University of Delaware)

Over the past two years, Toyota, Hyundai and Honda have launched vehicles that work on fuel cells, and carmakers such as BMW, GM and VW are involved in creating prototypes.

If only their power sources lasted longer and were economical, fuel cell vehicles could come into the mainstream faster. Presently, a team of Engineers at UD have created a technology that could make fuel cells more durable and cheaper.

They explain the technology in a paper published in Nature Communications on September 4th. Authors include Weiqing Zheng, a Research Associate at the Catalysis Center for Energy Innovation; Liang Wang, an Associate Scientist in the Department of Mechanical Engineering; Fei Deng, a Research Associate in Materials Science and Engineering; Stephen A. Giles, a Graduate Student in Chemical and Biomolecular Engineering; Ajay K. Prasad, Engineering Alumni Distinguished Professor and Chair of the Department of Mechanical Engineering; Suresh G. Advani, George W. Laird Professor in the Department of Mechanical Engineering; Yushan Yan, Distinguished Engineering Professor in the Department of Chemical and Biomolecular Engineering and the Associate Dean for Research and Entrepreneurship for the College of Engineering; and Dionisios Vlachos, Allan and Myra Ferguson Professor of Chemical and Biomolecular Engineering and Director of the Catalysis Center for Energy Innovation.

Cleaner energy, lower cost

Hydrogen-powered fuel cells are a green alternative to internal combustion engines because they generate power through electrochemical reactions, without causing any pollution.

Materials known as catalysts trigger these electrochemical reactions. Platinum is the most popular catalyst in the type of fuel cells used in vehicles.

However, platinum is costly. The metal costs about $30,000/kg.

Therefore, the UD team created a catalyst of tungsten carbide, which costs about $150/kg. They made tungsten carbide nanoparticles in a unique way, much smaller and more scalable than earlier techniques.

“The material is typically made at very high temperatures, about 1,500 °C, and at these temperatures, it grows big and has little surface area for chemistry to take place on,” Vlachos said. “Our approach is one of the first to make nanoscale material of high surface area that can be commercially relevant for catalysis.”

The tungsten carbide nanoparticles were made using a series of steps including hydrothermal treatment, separation, reduction, carburization and more.

We can isolate the individual tungsten carbide nanoparticles during the process and make a very uniform distribution of particle size.

Weiqing Zheng, Author and Research Associate, the Catalysis Center for Energy Innovation

Subsequently, the team added the tungsten carbide nanoparticles into the membrane of a fuel cell. Automotive fuel cells, known as proton exchange membrane fuel cells (PEMFCs), have a polymeric membrane. This membrane divides the cathode from the anode, which splits hydrogen (H2) into ions (protons) and supplies them to the cathode, which discharges current.

The plastic-like membrane starts to wear out in time, particularly if it has to endure too many wet/dry cycles, which can take place easily as heat and water are generated during the electrochemical reactions in fuel cells.

When tungsten carbide is added into the fuel cell membrane, it humidifies the membrane at a level that enhances performance.

The tungsten carbide catalyst improves the water management of fuel cells and reduces the burden of the humidification system.

Liang Wang, an Associate Scientist, the Department of Mechanical Engineering

The Researchers also discovered that tungsten carbide traps destructive free radicals before they can degrade the fuel cell membrane. Thus, membranes containing tungsten carbide nanoparticles last longer than traditional ones.

The low-cost catalyst we have developed can be incorporated within the membrane to improve performance and power density. As a result, the physical size of the fuel cell stack can be reduced for the same power, making it lighter and cheaper. Furthermore, our catalyst is able to deliver higher performance without sacrificing durability, which is a big improvement over similar efforts by other groups.

Ajay K. Prasad, Engineering Alumni Distinguished Professor and Chair of the Department of Mechanical Engineering

The UD Researchers used innovative approaches to examine the durability of a fuel cell made with tungsten carbide. They used a scanning electron microscope and focused ion beam to get thin-slice images of the membrane, which they scrutinized with software, rebuilding the 3D structure of the membranes to establish fuel cell longevity.

The team has applied for a patent and plans to commercialize their technology.

“This is a very good example of how different groups across departments can collaborate,” Zheng said.