Nov 15 2017

A recent study led by researchers at the Department of Energy’s Joint BioEnergy Institute (JBEI), based at Lawrence Berkeley National Laboratory (Berkeley Lab), shows the significance of microbial communities as a source of stable enzymes that could be applied to convert plants to biofuels.

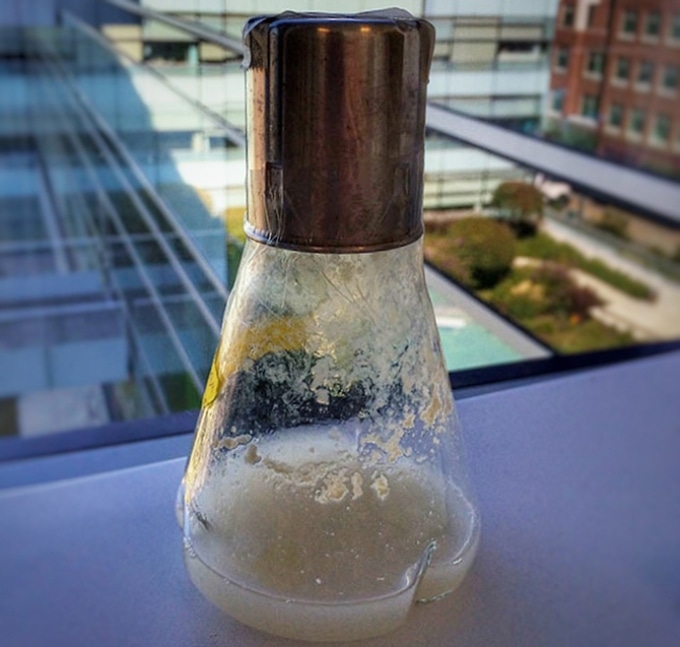

This 50-milliliter flask contains a symbiotic mix of bacteria derived from compost that was maintained for three years. (Credit: Steve Singer/JBEI)

This 50-milliliter flask contains a symbiotic mix of bacteria derived from compost that was maintained for three years. (Credit: Steve Singer/JBEI)

The study, just published in the journal Nature Microbiology, talks about the discovery of new types of cellulases, enzymes that aid in breaking down plants into ingredients that can be used to make bioproducts and biofuels. The cellulases were cultured from a microbiome. Using a microbial community deviates from the approach normally taken of using isolated organisms to get enzymes.

The researchers initially examined the microbial menagerie found in a few cups of municipal compost. Metagenomic analysis at the DOE Joint Genome Institute (JGI) of the microbiome helped expose that 70% of the enzymatic activity started from cellulases created by a bunch of uncultivated bacteria in the compost. They discovered that the enzymes without difficulty broke down the cellulose in plant biomass into glucose at temperatures up to 80 °C.

Here we’re cultivating an entire community of microbes to access enzymes that we couldn’t get from isolates. Some microbes are difficult to culture in a lab. We are cultivating microbes living in communities, as they occur in the wild, which allows us to see things we don’t see when they are isolated. This opens up the opportunity to discover new types of enzymes that are only produced by microbes in communities.

Steve Singer, Senior Scientist, Biological Systems and Engineering Division, Berkeley Lab and Director of Microbial and Enzyme Discovery, JBEI

The bacterial population, Candidatus Reconcilibacillus cellulovorans, produced cellulases that were arranged in extraordinarily robust carbohydrate-protein complexes, a structure never before seen in isolates. The stability of the new cellulase complexes makes them appealing for applications in biofuels manufacture, the study authors said.

“The enzymes persist, even after a decline in bacterial abundance,” said Singer, who compared the microbial community with sourdough starters fermented from friendly bacteria and wild yeast. “We kept the microbial community cultivation going for more than three years in the lab.”

This stability is a main advantage compared to other cellulases that degrade more quickly at high temperature, the researchers said.

To establish whether the enzyme production can be scalable for industrial applications, JBEI researchers partnered with researchers from the Advanced Biofuels and Bioproducts Process Demonstration Unit (ABPDU) at Berkeley Lab, a scale-up facility set-up by DOE to help speed up the commercialization of biofuels research findings.

Researchers at JBEI, a DOE Bioenergy Research Center, were able to create 50 ml samples, but in almost six weeks, the researchers at ABPDU scaled the cultures to a volume 6,000 times larger – 300 liters – in industrial bioreactors.

The lead author of the study is Sebastian Kolinko, who worked on the study as a JBEI postdoctoral researcher.

Other co-authors on this research include researchers from Taipei Medical University, the University of Georgia, the Manheim University of Applied Sciences, and Technical University of Braunschweig in Germany.

JGI is a DOE Office of Science User Facility. This study was mainly supported by the DOE Office of Science and the DOE Office of Energy Efficiency and Renewable Energy.