Nov 22 2017

As we make progress toward more sustainable ways of powering our way of life, there is a pursuit to bridge the gap between the carbon dioxide-emitting fossil fuels we depend on for our most fundamental needs, and the cleaner, but not yet economically attainable alternative technologies.

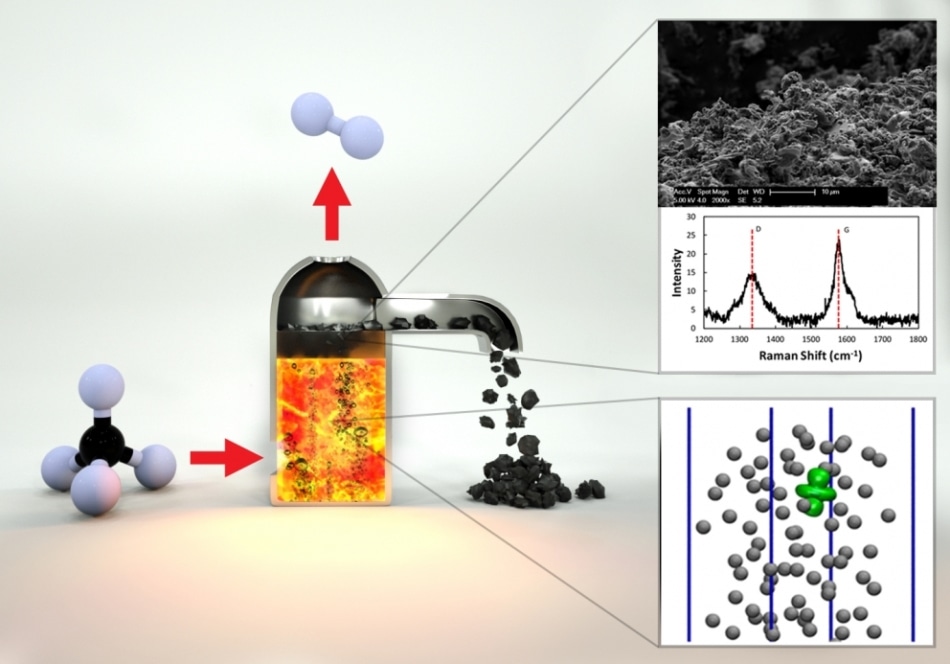

Hydrogen Production with a Ni-Bi molten catalyst (Photo Credit: Brian Long)

Hydrogen Production with a Ni-Bi molten catalyst (Photo Credit: Brian Long)

To achieve this, a team at UC Santa Barbara has considered methods by which currently inexpensive and plentiful methane (CH4) can be reduced to clean-burning hydrogen (H2) at the same time preventing the formation of carbon dioxide (CO2), which is a greenhouse gas. The team’s report, “Catalytic molten metals for the direct conversion of methane to hydrogen and separable carbon,” appears in the Science journal.

In the U.S., methane will be the heart of our economy for four or five decades, and figuring out ways to use it more sustainably is what motivates us. This paper was an interesting angle on something we’ve been looking at for a long time.

Eric McFarland, Professor, Chemical Engineering, UCSB

Methane is a product of both natural and man-made processes. It is the primary component of natural gas and is a key source of fuel for heating, cooking and powering our homes. Methane is also used in transportation and manufacturing. Methane, as a waste product, is a more potent greenhouse gas than carbon dioxide. Hence, it is the focus of numerous efforts to capture and reduce such emissions.

Steam methane reforming (SMR) is the most common process for producing commercial hydrogen and has been commercialized for decades. However, the researchers point out that SMR consumes notable amounts of energy and certainly produces carbon dioxide, which is usually released into the atmosphere. When the process was launched, CO2 was not considered an issue. However, as we became more conscious of greenhouse gases, it has snowballed into a universal concern.

The cost of operating the SMR process, and the potential additional costs of carbon taxes and carbon sequestration, puts hydrogen production by SMR at risk for considerable cost increases. This is particularly true in smaller scale operations that might provide the hydrogen required for fuel cell vehicles.

The UCSB team includes a long-established collaboration on catalytic methods to natural gas conversion between Theoretical Chemist and Professor Horia Metiu and McFarland. Along with Chemical Engineering Professor Michael Gordon, they started exploring the use of molten salts and molten metals as interesting and unfamiliar catalytic systems. Metiu’s theoretical work recommended that different combinations of metals in molten alloys could provide increased catalytic activity for converting methane into solid carbon and hydrogen.

The researchers have advanced a single-step method through which methane can be converted into hydrogen, which is simpler and possibly inexpensive compared to traditional SMR methods, and results in a solid form of carbon that can be effortlessly transported and stored indefinitely.

You introduce a bubble of methane gas into the bottom of a reactor filled with this catalytically active molten metal. As the bubble rises, the methane molecules hit the wall of the bubble and they react to form carbon and hydrogen.

Eric McFarland

Eventually, by the time the methane bubble reaches the surface, it has separated into hydrogen gas, which is released at the top of the reactor; then, carbon solids that float to the top of the liquid metal can be skimmed off, added McFarland. Compared to standard methods that depend on reactions that occur on solid surfaces, the molten metal alloy surfaces are not deactivated by the carbon accumulation and can be reused indefinitely. The combination of an active liquid metal and its solubility to hydrogen permits the melt to take up moderately more hydrogen and carbon than may be present within the gas bubbles. This allows the process to be efficient with very high-pressure methane in order to produce high-pressure hydrogen.

You’re really allowing yourself to pull all the products away from the reactants and that causes the equilibrium to be shifted toward the products. The process in principle can operate at high pressure and still get very high methane conversion.

Eric McFarland

According to McFarland, the ecosystem for deploying this kind of technology already exists, given existing infrastructure for processing hydrocarbons such as coal and natural gas, the current abundance of methane, and industry and legislative efforts to tighten up the capture of fugitive emissions. He added that the research has captured the attention and support of Royal Dutch Shell. The electricity generated from hydrogen derived by this zero-carbon dioxide process would be inexpensive than prevalent rates for solar energy, which, while eventually more sustainable, is not price competitive with fossil fuels today.

“If the entire world is wealthy, then wind and solar would be sufficiently low cost to be widely deployed, but it’s not cheap enough for the world that we have today,” said McFarland.

From an emissions standpoint, it is particularly important to deploy low-cost, low-emissions technologies in countries such as China, which is currently the world’s largest emitter of greenhouse gases, he added. Africa and India, which have huge and growing hydrocarbon consumptions, would benefit from such technology as well; they are, however, not rich enough to have the luxury of solar panels.